Medical & Health Care

324 products.

Filter by business area

[Close]

142 products.

[Close all]

Solutions for Pharmaceuticals

[Close]

Mitsubishi Chemical offers comprehensive solutions for medical devices and pharmaceutical packaging, leveraging its deep expertise and proven strong presence in the market over the years. We are expanding our global presence across a wide range of medical fields, providing high-performance resins, films, and tablet packaging for primary packaging in direct contact with pharmaceutical products. Additionally, we supply materials for single-use manufacturing components in pharmaceutical market. Our expert team is ready to recommend the ideal materials and technologies to suit your specific application. Please contact us today to learn more.

Biocatalyst

[Close]

We launched the world's first biocatalytic industrial production of acrylamide in 1985 and have been offering this product since 1999.

DURABIO™ is a bio-based polycarbonate resin derived mainly from plant-based isosorbide. Compared with conventional polycarbonate resin (hereafter abbreviated PC resin) made from bisphenol A (hereafter abbreviated BPA), DURABIO™ features high transparency, excellent optical properties, and outstanding scratch resistance. Its puncture impact behaviour are comparable to those for PC resin. DURABIO™ is a plant-derived polymer but is not biodegradable. It has excellent durability, making possible its deployment in a wide variety of applications such as for optical ・energy related components, a substitute for high-performance glass components, as well as for electronic equipment ・ automotive housings ・ interior and exterior decor.

BioPTMG is a polyether polyol manufactured from plant-derived raw materials.

BioPTMG has the same performance as petroleum-derived PTMG as a raw material for polyurethane and polyester resins and has excellent impact, wear and hydrolysis resistance, flexibility at low temperatures, etc. Taking advantage of these characteristics, it can be used in a wide range of fields, from interior and fashion to industrial materials.

- Grades:

- BioPTMG650、BioPTMG1000、BioPTMG2000、BioPTMG3000

- Japan, Chemical Substances Control Law:

- (7)-129

- Japan, Poisonous and Deleterious Substances Control Law:

- Not applicable.

- Japan, Fire Services Law:

- Hazardous Material Class 4 Petroleums No.4 Hazardous Rank III(BioPTMG650)

Combustible Materials, Flammable Solids(BioPTMG1000, 2000, 3000)

PTMG (Poly(tetramethylene ether)glycol / PTMG) is a linear polyether glycol with hydroxyl groups on both ends. As a polyol, it reacts readily with isocyanates (for example MDI, TDI), etc. to make resins with excellent properties.

- Grades:

- PTMG250、PTMG650、PTMG850、PTMG1000、PTMG1300、PTMG1500、PTMG1800、PTMG2000、PTMG3000、PTMG3200(developed grade in mass production)

- Japan, Chemical Substances Control Law:

- METI-No. 7-129

- Japan, Poisonous and Deleterious Substances Control Law:

- Not applicable.

- Japan, Fire Services Law:

- Hazardous Material Class 4 Petroleums No.3 Hazardous Rank III (PTMG250)

Hazardous Material Class 4 Petroleums No.4 Hazardous Rank III (PTMG650,850)

Combustible Materials, Flammable Solids (PTMG1000, 1300, 1500, 1800, 2000, 3000, 3200(developed grade in mass production))

Maleic anhydride is produced by oxidation of benzene or a C4 hydrocarbon such as butane in the presence of a vanadium oxide catalyst. Maleic anhydride can be converted to maleic acid by hydrolysis and to esters by alcoholysis.

- EINECS: No. 203-571-6

- Japan, Chemical Substances Control Law: METI-No. 2-1101

- Japan, Industrial Safety and Health Law: Dangerous Goods and Toxic Substances Whose Names Should be Labeled and be Notified Appended Table 2-1978

- Japan, Poisonous and Deleterious Substances Control Law: Not applicable.

- Japan, Fire Services Law: Not applicable.

THF (Tetrahydrofuran) is a stable compound with relatively low boiling point and excellent solvency. It is widely-used for dissolution and reaction of various substances. Also it is used as a starting material for the synthesis of poly(tetramethylene ether) glycol (PTMG), etc. Since 1982, Mitsubishi Chemical's Tokai plant has produced high-purity, high-quality THF from butadiene using our proprietary technology.

- EINECS: No. 203-726-8

- Japan, Chemical Substances Control Law: METI-No. 5-53

- Japan, Industrial Safety and Health Law: No. 5-53

- Japan, Industrial Safety and Health Law: Dangerous Goods and Toxic Substances Whose Names Should be Labeled and be Notified Appended Table 2-1278

- Japan, Poisonous and Deleterious Substances Control Law: Not applicable.

- Japan, Fire Services Law: Hazardous Material Class 4 Petroleums No.1 (water-soluble liquid). Hazardous Rank II

- U.N. Class: 3

- U.N. No.: UN2056

NMP (N-Methyl-2-Pyrrolidone) is a polar solvent with outstanding characteristics. It has a wide range of applications because it offers very high solvency, high boiling point, low freezing point, and ease of handling.

- EINECS: No. 212-828-1

- Japan Chemical Substances Control Law: METI-No. 5-113

- Japan, Industrial Safety and Health Law: No. 8-1-1014

- Japan, Industrial Safety and Health Law: Dangerous Goods and Toxic Substances Whose Names Should be Labeled and be Notified Appended Table 2-2108

- Japan, Poisonous and Deleterious Substances Control Law: Not applicable.

- Japan, Fire Services Law: Hazardous material Class 4 Petroleums No.3 (water-soluble liquid).

GBL has a wide range of practical applications because of its low freezing point, high boiling point, and a unique combination of solvent and electrical properties. It has applications as a solvent for special resins, in photography, in batteries, and as an electrolyte. Also a number of derivatives are synthesized from GBL.

- EINECS: No. 202-509-5

- Japan Chemical Substances Control Law: METI-No. 5-3337

- Japan, Industrial Safety and Health Law: No. 5-3337

- Japan, Industrial Safety and Health Law: Dangerous Goods and Toxic Substances Whose Names Should be Labeled and be Notified Appended Table 2-412

- Japan, Poisonous and Deleterious Substances Control Law: Not applicable.

- Japan, Fire Services Law: Hazardous material Class 4 Petroleums No.3 (water-soluble liquid).Aprotic, polar solvent.

12BG (1,2-butanediol) is a branched glycol that has a primary hydroxyl group and a secondary hydroxyl group on adjacent carbon atoms. Mitsubishi Chemical Corporation offers two grades of purity. Both can be reacted with a dicarboxylic acid (e.g., phthalic acid or adipic acid) for use as a polyester polyol or a plasticizer, or reacted with an unsaturated dicarboxylic acid (e.g., maleic anhydride) for use as a raw material for unsaturated polyester resin. The high-purity grade 12BG is suitable for use as a solvent for inks and as a raw material for surfactants.

- EINECS: No. 209-527-2

- Chemical Substance Control Law (CSCL): METI-No. 2-235

- Japan, Industrial Safety and Health Act (ISHA): No. 2-235

- Japan, Poisonous and Deleterious Substances Control Act: Not applicable.

- Japan, Fire Service Act:Hazardous Materials, Category IV—Class III petroleums (water soluble liquids)

14BG (1,4-Butanediol) is a straight chain glycol with hydroxyl groups on both ends. It is used as a raw material for high performance polyester and polyurethane resins as well as for industrial chemicals like tetrahydrofuran and gamma-butyrolactone. Since 1982, Mitsubishi Chemical's Tokai plant has produced high-purity, high-quality 14BG from butadiene using our proprietary technology.

- EINECS: No. 203-786-5

- Japan, Chemical Substances Control Law: METI-No. 2-235

- Japan, Industrial Safety and Health Law: No. 2-235

- Japan, Poisonous and Deleterious Substances Control Law: Not applicable.

- Japan, Fire Services Law: Hazardous material Class 4 Petroleums No.3 (water-soluble liquid).

Polycarbonatediol, BENEBiOL™

[Close]

Polycarbonatediol(PCD) is a linear polycarbonate with hydroxyl groups at both ends. It easily reacts with isocyanate compounds(e.g. MDI, TDI, IPDI, H12MDI), and generates polymers with characteristics such as durability and chemical/hydrolysis resistance. BENEBiOL™ is the biomass-based PCD developed by our proprietary manufacturing technology. Because of “key monomer“ of each grade, polyurethane resins based on BENEBiOL™ will show an outstanding property level with regard to flexibility and chemical/stain resistance for example, in addition to the characteristics of conventional PCD. Besides, your product will be equipped with unique touch and feeling.Biomass-based polycarbonatediol with superior characteristics

Characteristics of polyurethane resins based on BENEBiOL™

non-edible raw material is used for some grades

transparency, stain resistance, chemical resistance, durability, toughness, weather resistance

flexibility, soft feel and touch, high hardness, good fit

FORZEAS™ is a compounding resin developed by Mitsubishi Chemical Corporation using biodegradable and bio-based BioPBS™ and other materials. Each grade has its own unique features and can be used in various applications.

FORZEAS™ can be flexibly formulated depending on customers’ requirements for performance and bio-degradable/bio-based certification.

Biodegradable Polymer, BioPBS™

[Close]

Polybutylene succinate (PBS) is the biodegradable plastic that decomposes into water and carbon dioxide with the microorganism under the soil. PBS has a high heat resistance among the general biodegradablility resin, and PBS has high compatibility with a fiber. Using these goodness, it's possible to achieve the performance which can't be shown by itself as the compound with other resin and material.duct life cycle.

NOVADURAN™ PBT resin has excellent electrical insulation performance, good chemical resistance, moldability. Taking advantage of these characteristics, it has been widely used as a material for automotive ,E&E, and high-performance film applications.

XANTAR™ PC has excellent transparency, impact resistance, flame reistance, heat resistance, electrical properties.

Taking advantage of these characteristics, it has been widely used as a material for automotive ,E&E,

and high-performance extrusion applications.

Acrylic Sheet, SHINKOLITE™

[Close]

SHINKOLITE™ is the registered trade name of Mitsubishi Chemical's continuous cast acrylic sheet. Known as acrylic resin, this material has excellent weather resistance, stainability, and processability properties, and so is used in many applications such as signage, display, large water tanks, LCDs, and light guide plates. We will continue to leverage these properties and develop new products such as the flame-retardant and impact-resistant grades of SHINKOLITE. It is our goal to provide environmentally friendly products that make society safer and help people to have more comfortable and prosperous lives.

AQUAMICRON™ is a high-precision reagent designed for a wide range of moisture measurement applications using the Karl Fischer method. Our comprehensive lineup includes reagents for both coulometric and volumetric titration, as well as certified water standards.

For coulometric titration, we offer combinations of anolyte (e.g., AX etc.) and catholyte (CXU), along with convenient single-solution electrolytes (FLS) that simplify maintenance. For volumetric titration, our portfolio includes traditional pyridine/chloroform-based titrants (SS series), as well as environmentally friendly pyridine-free and chloroform-free alternatives (SS-Z series), complemented by a variety of dehydration solvents tailored to different sample types.

This website provides access to detailed catalog, technical manual, instructional videos, FAQ, and request forms for SDS and COA documentation.

Injection Molded Products

[Close]

The High-performance Molding Systems Division has injection molding production bases in Nagahama City in Shiga Prefecture and Ogaki City in Gifu Prefecture. We provide various high-quality products primarily in the automotive industry via a consistent production process from die manufacturing to product delivery so as to meet our customers' needs. Our in-house production system incorporates many different coating technologies in addition to our injection molding technologies.

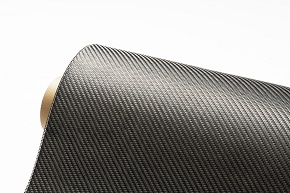

Roller (CARBOLEADER ™)

[Close]

CARBOLEADER™ is a carbon roller that simultaneously offers light weight, high rigidity, and a high critical number of revolutions. It is used for a wide range of applications, including separators for rechargeable batteries, for optical applications and all kinds of films, for printing, and paper manufacture. It can significantly increase productivity and reduce costs by improving production quality and speed, and reducing defect rates.

C/C composite, C/SiC composite

[Close]

C/C (carbon fiber reinforced carbon) composites are made of carbon matrix reinforced with carbon fiber, and have high strength, high elasticity, high toughness, and ultra-high heat resistance, and can be used at temperatures above 1,000ºC.

C/SiC, also known as ceramic matrix composite (CMC), is a composite material with a ceramic matrix, and our CMC is reinforced with carbon fiber. It has higher strength and elasticity than C/C composite, and can be used in a wider variety of applications.

Carbon fiber composite materials, also known as carbon fiber reinforced plastics (CFRP), are composite materials made of carbon fibers and resin (mainly epoxy resin).

As light, strong, and hard materials, they are used in wide range of applications such as sporting goods, industrial, aircraft and automobile components. By selecting suitable resin, it is possible to add features like heat resistance, impact resistance, and flame retardant, and thus provide superior characteristics not found in conventional metals and ceramics to enable a reduction in the weight of parts, give freer design.

Carbon Fiber Pellets

[Close]

Carbon fiber pellets are thermoplastic molding materials created by blending carbon fiber with various resins to achieve performance that is superior to conventional reinforced resins. Advanced physical properties can be achieved by combining different base resins and carbon fibers, according to the specific application.

Carbon Fiber FMC (CF-SMC)

[Close]

Carbon Fiber FMC (CF-SMC) is a sheet-type intermediate material made of cut high-strength carbon fiber impregnated with thermosetting resin. This material can be press molded, substantially reducing molding time compared to conventional autoclave or oven molding.

In addition, compared with carbon fiber intermediates of Continuous fibers, the random arrangement of Short fibers ensures fluidity and makes it possible to mold intricately shaped parts like those with ribs and bosses.

Carbon fiber is a high-strength and high-elastic modulus material, yet its specific gravity is only one-fourth that of iron. It, therefore, enables high strength, high rigidity, and weight-saving in a wide variety of applications.

Carbon fiber tow, made of bundles of untwisted filaments, is the essential material in our carbon fiber product line.

Carbon Fiber Fabrics

[Close]

Carbon fiber fabrics have excellent drape properties which make them ideal for 3D shape applications. Due to the outstanding design possibilities they offer, carbon fabrics are also in high demand for applications that require visual appeal. As well as their design potential, carbon fabric materials offer excellent layup efficiency. You can layup a single ply in two directions.

Carbon Chopped Fiber is a product made by chopping carbon fiber tow.

Carbon Milled Fiber is a product made by grinding milling chopped fiber into a powder (milled) form.

Chopped fiber is typically around 3 to 6 mm long, while milled fiber is typically less than 200 µm long. Both of these materials are used to enhance the physical properties of thermoplastic resins and rubbers, and to increase electrical and thermal conductivity.

Polyvinyl Alcohol is a pharmaceutical excipient and listed in major official compendia.

It is widely used in many countries including Japan, the United States, and Europe.

Our GOHSENOL™ EG conforms to pharmacopoeia excipients including JPE*

1,USP*2 and EP*3

- *1Japanese Pharmaceutical Excipients (JPE)

- *2United States Pharmacopeia (USP)

- *3European Pharmacopoeia (EP)

Food Additive, Acetic Acid

[Close]

X-ray Scintillator Screen, DRZ™

[Close]

Scintillator is a material that convert radial ray such as X-ray into the visible light. By using with a light detector such as TFT, CCD, CMOS sensors, The image can be efficiently converted to a digital image.

Mitsubishi Chemical has its own phosphor manufacturing technology and processing know-how, including the DRZ series used for medical X-ray diagnostic imaging and baggage inspection, We have commercialized excellent scintillators for digital X-ray equipment such as Short Decay and Low Afterglow Type used for high-speed line sensors for contamination inspection.

Capable of advanced separation and purification in chromatographic separation of products thanks to smaller particle size than DIAION™ HP20 and SP207, which have excellent adsorption properties. This series consists of HP20SS, SP20SS with smaller particle size, and SP207SS.

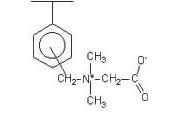

DIAION™ AMP03 is an amphoteric ion-exchange resin with a quaternary ammonium group and carboxy group incorporated into the crosslinked polystyrene backbone. Thanks to uniform 260 µm beads size, AMP03 realizes sharp elution peak in the separation of electrolytes from non-electrolytes, between electrolytes (sodium chloride and sodium sulfate), etc.

MCI GEL™ packing materials for high performance liquid chromatography are synthetic polymer products for use as ion exchange resins, non-functional reverse-phase support, hydrophilic porous gels, etc. Particle size ranges from 4µm to more than 100µm. Quantities for analytical applications up to production-scale fractionation are available. We are prepared to supply materials such as ion exchange resins for glycoamino acid analysis, polymer adsorbent for reverse-phase chromatography, various column packings for protein separation, etc.

HPLC packed columns, MCI GEL

[Close]

These are HPLC separation columns that achieve high-resolution separations utilizing our proprietary column packing technology that features the high-quality MCI™ GEL packing material. MCI GEL packed columns serve application fields such as amino acid analysis, protein analysis, common organic compound analysis, and ion chromatography.

The Synthetic Adsorbents are cross-linked polymer spheres which provide specific surface area of 500-1200m2/dry-g with their porous structure. Available products include the aromatic-based HP series, the aromatic-based SP series, and the methacrylate ester-based HP2MGL. They are used for the adsorption purification of peptides, proteins, polyphenols, cephalosporin C, etc. as well as for the removal of bitter-tasting substances from fruit juices.

A chelating resin has a functional group that is capable of forming a chelate (complex) with a metal ion. The specific metals that can form chelates with the functional group can be captured. In the DIAION™ CR Series, there are three product types: (1) for common metals -- DIAION™ CR11 with the iminodiacetic acid functional group, (2) for metals other than alkali metals (Na, K, etc.) or alkaline earth metals (Ca, Mg, etc.) -- DIAION™ CR20 with the polyamine group, and (3) for selectively capturing boric acid --- CRB03 and CRB05 with the methylglucamide group.

The low-odor, low-leachable anion exchange resin reduces the release of total organic carbon (TOC) and amines to prevent offensive odors.

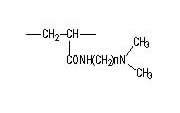

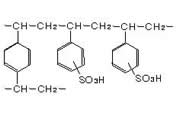

The weakly basic anion exchange resins use either a polystyrene or polyacrylic ester frame and a primary-ternary amino group as the functional group. Although the anion of a salt like NaCl or Na2SO4 cannot be exchanged, the exchange of an anion of a mineral acid such as HCl and H2SO4, or the salt of a weak base like NH44Cl can be carried out.

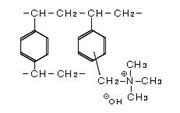

An amino functional group is incorporated into the anion exchange resin enabling the exchange of anions like the Cl- ion and the SO4-- ion. Strongly basic anion exchange resins and weakly basic anion exchange resins can be defined according to the basic strength of the amino functional group.

The ion exchange resin that has a quaternary ammonium group is strongly alkaline and dissociates just like NaOH and KOH. Therefore it is called a strongly basic anion exchange resin.

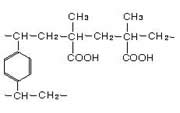

The weakly acidic cation exchange resins have the carboxylic acid group (-COOH) as the exchange group. There are two kinds --- a methacrylic acid type and an acrylic acid type. The acrylic acid weakly acidic cation exchange resin is used for processing water with high carbonate hardness. The methacrylic acid type is used for purification of antibiotics and amino acids.

The strongly acidic cation exchange resins are bead-like products which have a sulfonic acid group in the cross-linked styrene frame. They can be used across the full pH range (0-14), and are relatively stable to temperature, even withstanding high temperatures of 100-120℃. They are used in a wide variety of fields including water purification, water softening, wastewater treatment, purification of pharmaceuticals and food, and catalysis.

Water-soluble films developed by a specialist in chemical materials

HI-SELON™ is a water-soluble film made from polyvinyl alcohol.

With its excellent heat-sealing property and printability, HI-SELON™ is ideal for use as a packaging materials, but it also provides many other advantages, including high solvent resistance and barrier performance, which are used as materials for packaging of liquid detergent capsules.

PET Bottles

[Close]

Our lineup of PET bottles focuses on meeting the needs of food, seasoning, and alcoholic beverage customers. We are also developing cosmetics, medicine, and industrial applications of our high-barrier bottles originally designed for the food and seasoning industry to preserve freshness and extend shelf life.

DIAMIRON is a multilayer film combining polyamide, EVOH, polyolefin etc. by our proprietary technology. No chlorinated resin is used. Flat and tube types are available. A wide range of applications as deep drawing and vacuum packaging include food packaging, medical devices, and industrial materials.

DIAMIRON is produced under ISO9001 and FSSC22000-compliant quality control.

Applications

- For food packaging

- For medical device packaging

- For transfusion bags

- For industrial materials

Transparent gas barrier sturucture, SiOx vacuum coated technologies on OPET, OPA. Excels in gas barrier properties as well as aroma substances, chemical resistance and robust processability for printing, bag making process and consistency of oxygen / humidity barrier properties under high temperature and humidity. TECHBARRIER can be widely used for packaging materials in medical, pharmaceutical, industrial and food market.

We are able to create co-extruded films by using our unique co-extrusion technology to merge multiple resins together in a die.

This high-performance film inherits the properties of each resin used.

We can customize the properties of the film with functionality based on your needs, such as producing a film with high barrier properties.

We constructed a special, clean production environment to produce DIAMIRON as an extremely high-quality primary container. This material is used in such products as transfusion and infusion bags and sterile blister packs for medical supplies.

DIAMIRON is produced at the Azai Plant under ISO 9001 and FSSC 22000-compliant quality control.

Visit the product website for more information.

Applications

- Sterile blister packs for medical supplies

- Transfusion bags

This plastic sheet is used to manufacture press-through packages (PTP) manufactured under Good Manufacturing Practices (GMP) required for medical packaging materials. This material complies with Notification 370 from the Ministry of Labour and Welfare issued in 1959, the Japan Hygienic PVC Association (JHP) standards, and Japan Hygienic Olefin and Styrene Plastics Association PL standards. This material is also registered in the US Food and Drug Administration (FDA) drug master file.

We use various testing equipment such as actual packaging machines used by the pharmaceuticals industry to ensure packaging properties of each material.

We are engaged in development to improve stability of pharmaceuticals manufacturing as well as incorporate the perspective of users including both patients and pharmacists.

Heat-Shrinkable Tube, HISHITUBE™

[Close]

Zelas™ CP is a polymer compound products based on amorphous polyolefin with high transparency, which is designed to be suitable as a material for medical devices such as medical vials and syringes that require low adsorption of pharmaceuticals and high hygiene.

Zelas™CP has excellent heat-sealing and dissimilar-material adhesion properties, and can be applied as an inner layer of two-color molding or backing, contributing to improved design of medical device components.

※For industrial applications and when good adhesion to metal is required, we introduce Tefabloc™ CP .

Tefabloc™ CP is based on amorphous polyolefins, which not only have high transparency, but also have unique properties not found in other cyclic olefins (COP/COC).

We are developing products for optical applications such as solar panel cover materials utilizing its transparency, and for high-speed communication applications such as 5G and 6G utilizing its low dielectric properties, and can also design products according to customer requirements.

※For medical application, we introduce Zelas™ CP .

ZELAS™ are polymers designed for medical applications including R-TPO, specialty TPE compounds and tie layer resins. Specific solutions designed for film, tube and injected components for medical applications.

Synthetic Paper , YUPO™

[Close]

"YUPO" is a synthetic paper made from polypropylene resin as its primary material. It offers extraordinary beauty, strength and flexibility. YUPO combines the advantages of both paper and plastic film, and thanks to its unique qualities, it is used widely in several fields, including the commercial printing, packaging and communication paper.

Separation & Purification System

[Close]

Water Treatment System

[Close]

Resin compound product

[Close]

We are a one-stop shop for the development and manufacturing of compound products tailored by application and with plastics as their raw materials. The industries we serve are various and include automobiles, home appliances, and health care. We manufacture products to order, tailored to customers’ needs, using proprietary compound technologies.

Terephthalate Plasticizer

[Close]

Phthalate Plasticizers

[Close]

Adipate Plasticizer

[Close]

Other Plasticizers

[Close]

Water Purifier, Cleansui

[Close]

Home water purifier using hollow fiber membrane material. We off a full lineup of high-performance water purifiers including faucet-mounted models, pitcher models, built-in models, and commercial models. We provide the water necessary for life through products to stockpile water for long periods of time and water-softening shower heads with built-in cartridges.

Refer to the Cleansui website for more information.

- Product Finder

-