Carbon Fiber Div.

4products.

[Close all]

Carbon Fiber Tow (Continuous fiber)

[Close all]

Carbon fiber is a high-strength and high-elastic modulus material, yet its specific gravity is only one-fourth that of iron. It, therefore, enables high strength, high rigidity, and weight-saving in a wide variety of applications.

Carbon fiber tow, made of bundles of untwisted filaments, is the essential material in our carbon fiber product line.

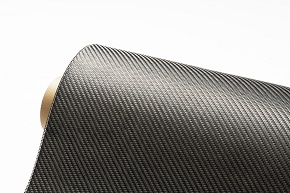

Carbon Fiber Fabrics

[Close all]

Carbon fiber fabrics have excellent drape properties which make them ideal for 3D shape applications. Due to the outstanding design possibilities they offer, carbon fabrics are also in high demand for applications that require visual appeal. As well as their design potential, carbon fabric materials offer excellent layup efficiency. You can layup a single ply in two directions.

Carbon Chopped Fiber is a product made by chopping carbon fiber tow.

Carbon Milled Fiber is a product made by grinding milling chopped fiber into a powder (milled) form.

Chopped fiber is typically around 3 to 6 mm long, while milled fiber is typically less than 200 µm long. Both of these materials are used to enhance the physical properties of thermoplastic resins and rubbers, and to increase electrical and thermal conductivity.

Structural Reinforcement Materials

[Close all]

Compared with conventional steel plate or concrete-jacketed reinforcements, REPLARK simplifies construction and shortens construction period by eliminating the need for heavy machinery. For its high strength, lightweight, high durability, and excellent workability, REPLARK has earned an outstanding reputation for the repair and reinforcement of bridge piers, floorboards, columns, chimneys, and for other structural applications.

e-Plate/Leadline: This repair and reinforcement material enables reinforcement by simply attaching or embedding prefabricated carbon fiber reinforced plastics (CFRP), without the need for resin impregnation or for layering the required amount of reinforcement, as in the case of repair and reinforcement using carbon fiber sheets, thereby reducing construction time and improving construction quality.

- Product Finder

-