Plastic Molded and Processed Products (Film & Sheet / Molding / Composite)

324 products.

Filter by Application

[Close]

88 products.

[Close all]

Acrylic Sheet, SHINKOLITE™

[Close]

SHINKOLITE™ is the registered trade name of Mitsubishi Chemical's continuous cast acrylic sheet. Known as acrylic resin, this material has excellent weather resistance, stainability, and processability properties, and so is used in many applications such as signage, display, large water tanks, LCDs, and light guide plates. We will continue to leverage these properties and develop new products such as the flame-retardant and impact-resistant grades of SHINKOLITE. It is our goal to provide environmentally friendly products that make society safer and help people to have more comfortable and prosperous lives.

Plastic Optical Fiber, Eska™

[Close]

ESKA is a plastic optical fiber product that exploits the excellent light-transmission properties of acrylic resins. It possesses a number of important characteristics not found in glass optical fiber, including light weight, flexibility, and easy processability. We are marketing ESKA for a wide number of applications in the fields of automotive networks, lighting, sensors, FA (Factory Automation) and data transmission.

Injection Molded Products

[Close]

The High-performance Molding Systems Division has injection molding production bases in Nagahama City in Shiga Prefecture and Ogaki City in Gifu Prefecture. We provide various high-quality products primarily in the automotive industry via a consistent production process from die manufacturing to product delivery so as to meet our customers' needs. Our in-house production system incorporates many different coating technologies in addition to our injection molding technologies.

Water-soluble films developed by a specialist in chemical materials

HI-SELON™ is a water-soluble film made from polyvinyl alcohol.

With its excellent heat-sealing property and printability, HI-SELON™ is ideal for use as a packaging materials, but it also provides many other advantages, including high solvent resistance and barrier performance, which are used as materials for packaging of liquid detergent capsules.

OPLFILM™ is the trade name of PVOH(PVA) (polyvinyl alcohol) film for use in polarizing film for liquid crystal displays (LCD). We provide wide-ranging technical expertise and optimum materials that maximize our polarizing film manufacturing experience.

PET Bottles

[Close]

Our lineup of PET bottles focuses on meeting the needs of food, seasoning, and alcoholic beverage customers. We are also developing cosmetics, medicine, and industrial applications of our high-barrier bottles originally designed for the food and seasoning industry to preserve freshness and extend shelf life.

Biaxially oriented polystyrene sheets were first commercialized in Japan. Polystyrene tends to crack during the thinning process. As such, biaxially oriented processing is used for this material to give it practical strength. This also gives the material excellent transparency and thermoformability. This material is used for many food packaging applications.

- *Santoclear is a registered trademark of Solutia Inc. and used here under license.

DIAMIRON is a multilayer film combining polyamide, EVOH, polyolefin etc. by our proprietary technology. No chlorinated resin is used. Flat and tube types are available. A wide range of applications as deep drawing and vacuum packaging include food packaging, medical devices, and industrial materials.

DIAMIRON is produced under ISO9001 and FSSC22000-compliant quality control.

Applications

- For food packaging

- For medical device packaging

- For transfusion bags

- For industrial materials

Heat-Shrinkable Film

[Close]

Transparent gas barrier sturucture, SiOx vacuum coated technologies on OPET, OPA. Excels in gas barrier properties as well as aroma substances, chemical resistance and robust processability for printing, bag making process and consistency of oxygen / humidity barrier properties under high temperature and humidity. TECHBARRIER can be widely used for packaging materials in medical, pharmaceutical, industrial and food market.

Bio-based Film, ECOLOJU™

[Close]

Acrylic Film, ACRYPLEN™

[Close]

We have been engaged since 1975 in the development, manufacture, and sale of acrylic (PMMA) films through a combination of our unique in-house polymer design and thin film forming technologies.

ACRYPLEN (acrylic film) features the excellent transparency, weatherability, suitability for heat-molding and lamination processing. In addition, it has outstanding UV protection, making it ideal for use as a construction material, a paint-alternative, and a retro reflective material, as well as for a wide range of applications in the field of optical engineering.

Mitsubishi Chemical is a pioneer in the development of acrylic films, and the Company’s lineup encompasses products with a wide variety of thicknesses, widths, and differing degrees of flexibility/rigidity.

We are able to create co-extruded films by using our unique co-extrusion technology to merge multiple resins together in a die.

This high-performance film inherits the properties of each resin used.

We can customize the properties of the film with functionality based on your needs, such as producing a film with high barrier properties.

We constructed a special, clean production environment to produce DIAMIRON as an extremely high-quality primary container. This material is used in such products as transfusion and infusion bags and sterile blister packs for medical supplies.

DIAMIRON is produced at the Azai Plant under ISO 9001 and FSSC 22000-compliant quality control.

Visit the product website for more information.

Applications

- Sterile blister packs for medical supplies

- Transfusion bags

Moisture Transmission Film

[Close]

This plastic sheet is used to manufacture press-through packages (PTP) manufactured under Good Manufacturing Practices (GMP) required for medical packaging materials. This material complies with Notification 370 from the Ministry of Labour and Welfare issued in 1959, the Japan Hygienic PVC Association (JHP) standards, and Japan Hygienic Olefin and Styrene Plastics Association PL standards. This material is also registered in the US Food and Drug Administration (FDA) drug master file.

We use various testing equipment such as actual packaging machines used by the pharmaceuticals industry to ensure packaging properties of each material.

We are engaged in development to improve stability of pharmaceuticals manufacturing as well as incorporate the perspective of users including both patients and pharmacists.

Heat-Shrinkable Tube, HISHITUBE™

[Close]

Sheets for Cards

[Close]

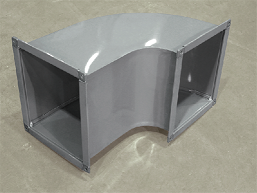

A high‑performance composite that bonds metal and plastic film under extreme pressure—no adhesives required.

Key Features

- Pure Mechanical Lamination

Metals and polymer films are fused through a proprietary process, delivering exceptional peel strength and durability without resin or adhesive layers. - Custom Combinations

Choose your ideal metal + film pairing, thickness and finish to match your exact specifications. - Broad Compatibility

- Metals:

- Aluminum、Stainless steel (SUS)、Electro galvanized steel (SECC)、Zn-Al-Mg alloy (ZAM)

[under development]Copper - Resin Films:

- Polyamide (PA)、Polypropylene (PP)、Ultra high molecular weight polyethylene (UHMWPE)、Fluoropolymers、PET (polyethylene terephthalate)

[under development]PC 、PBT 、PPS、PEI

Specifications & Custom Orders

- Width: up to 500 mm max.

(Actual maximum depends on metal type and thickness—please inquire for details.) - Thickness & Layering: fully customizable—mix and match metal and film layers as needed.

- Special Requests: if you don’t see your preferred metal or film listed, please contact us—many additional materials can be accommodated.

At Mitsubishi Chemical, we offer the high-performance engineering plastic film "SUPERIO™ UT". Leveraging our many years of accumulated technology and experience, we are currently mass-producing films made from PEI (polyetherimide) and PEEK (polyether ether ketone). These films have been adopted across a wide range of industries and applications, including automotive, electronics, and aerospace. To meet the increasingly diverse needs of our customers, we are actively engaged in the development and commercialization of an even broader range of high heat-resistant films. We also offer customized solutions tailored to specific customer requirements. If you are interested in high-performance engineering plastic films, please feel free to contact us.

Electronic Functional Materials

[Close]

Silicone rubber film, KEIJU™

[Close]

With a comprehensive lineup of polyester film, ranging from a few microns to 350 microns in thickness and featuring well-balanced characteristics such as mechanical properties and heat resistance. Customers across the globe in further increasing applications have been using DIAFOIL.

We integrate three technologies of Mitsubishi Chemicals, namely, excellent and proprietary material technologies, film-forming technology cultivated over many years and surface treatment technology with unique coating, and develop new markets with customers to become a leading global company.

Working closely with the polymer and engineering operations, our polyester film operations take advantage of the latest information and technology to make quality improvement and process enhancement. This allows us to meet a wide range of our customers' needs. In this way, we continue to strive to offer satisfaction to customers and build long-lasting, strong relationships. We are continuing to make efforts, devoting ourselves to R&D activities to provide even more sophisticated products.

Soarlite is the trade name of ethylene-vinyl alcohol copolymer for injection molding application as engineering plastics.

Soaresin™

[Close]

Soaresin™ is used as a stabilizer or purging agent for extrusion.

Synthetic Paper , YUPO™

[Close]

"YUPO" is a synthetic paper made from polypropylene resin as its primary material. It offers extraordinary beauty, strength and flexibility. YUPO combines the advantages of both paper and plastic film, and thanks to its unique qualities, it is used widely in several fields, including the commercial printing, packaging and communication paper.

Resin compound product

[Close]

We are a one-stop shop for the development and manufacturing of compound products tailored by application and with plastics as their raw materials. The industries we serve are various and include automobiles, home appliances, and health care. We manufacture products to order, tailored to customers’ needs, using proprietary compound technologies.

The sales company for Japan Polypropylene Corporation and Japan Polyethylene Corporation, sells polyolefin resins, such as polyethylene (PE) and polypropylene (PP), in quantities of 25 kg bags and in larger quantities. Please feel free to contact us.

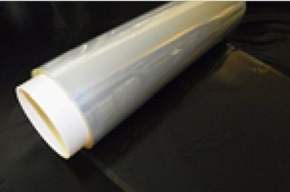

Airtight Sheet for Housing

[Close]

Airtight design of houses prevents indoor air from leaking outdoors and at the same time shuts outdoor air off, increasing the effectiveness of air conditioning, contributing to energy saving. Furthermore, airtight sheets prevent vapor generated indoors from entering heat-ray intercepting material, eliminating internal condensation and by maintaining performance of heat-insulating material and assists in the prevention of wood corrosion, improves the durability of houses.

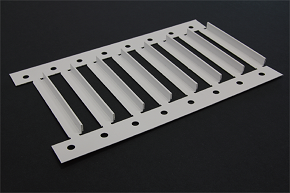

Plastic Filtering Plate

[Close]

Made form high quality polypropylene (PP), our wide range of filtering materials for filter press machines include lightweight filter plates with excellent chemical resistance and high impact strength, plastic membranes with superb thermal and chemical resistance, and filter-press-plate unit combined with anticorrosive plastic membrane.

Polycarbonate Sheet, HISHICARBO™

[Close]

Designing comfort and safety of diversifying exterior applications

Our polycarbonate sheets for exterior use are an easy-to-use transparent material with excellent weather and shock resistance. For this reason, it can be bent for installation to fit sashes at room temperature, responding to sophisticated design needs. It also increases the flexibility of future structures as flame resistant roof material to direct sunlight into a house.

HISHIMETAL is a composites material that is produced by laminating PVC film on a base material such as galvanized steel sheets, stainless steel sheets and aluminum sheets. PVC film is a general purpose film and we have employed it as a laminating film for many years.

This material is used in many different industries because it has metal strength and workability in addition to the design qualities and functional properties of plastic film.

EXUM incorporates galvanized steel sheets, stainless steel sheets, and aluminum alloy sheets as a base material. EXUM is a polyester-based plastic film-laminated steel sheet manufactured by our multi-layer extrusion technology.

This material is primarily used in interior applications due to the combination of metal strength, workability, and design qualities.

ALPOLIC is Aluminum Composite Material (ACM) composed of two sheets of aluminum and the thermoplastic core.

ALPOLIC has been global leading ACM since 1970s and has been used worldwide in more than 130 countries.

We have a variety of product lineups with design and function using different types of materials on surface and core materials

including ALPOLIC A1 which passed European fire classification A1 as the first ACM in the world, ALPOLIC/fr series which passed fire regulations around the world, and ALPOLIC/fr SCM with stainless steel on its surface.

For the details of products, visit ALPOLIC dedicated website.

- Product Finder

-