Low dielectric / Transparent / High weatherabilityTefabloc™ CP

Mitsubishi Chemical Corporation- Language

Tefabloc™ CP is based on amorphous polyolefins, which not only have high transparency, but also have unique properties not found in other cyclic olefins (COP/COC).

We are developing products for optical applications such as solar panel cover materials utilizing its transparency, and for high-speed communication applications such as 5G and 6G utilizing its low dielectric properties, and can also design products according to customer requirements.

※For medical application, we introduce Zelas™ CP .

Characteristics

[Close]

For Optical application

- 1.High transparency

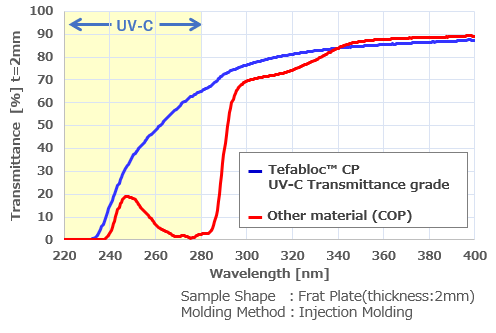

High transmittance in the UV to visible light range.

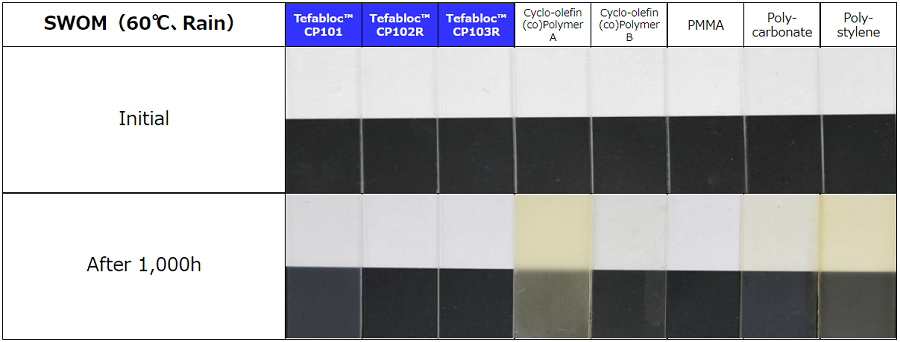

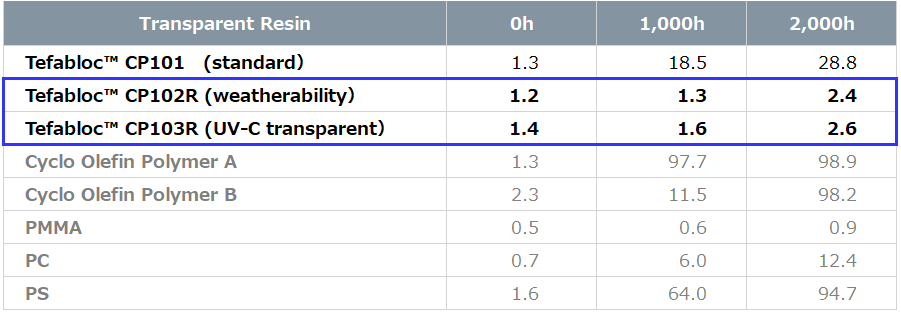

- 2.Excellent weatherability

Excellent weather resistance , Resistance to yellowing and applicable to applications that require long-term transparency.

Haze change by SWOM test(60℃,Rain)

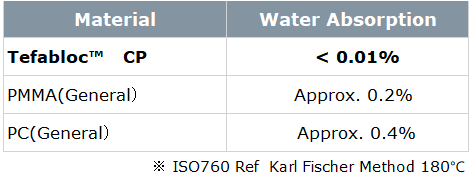

- 3.Excellent low moisture absorption

The olefin-based material has excellent low moisture absorption and can be used for outdoor applications.

- 4.Others

Insert molding provides strong fusion bonding with polyolefin resins such as polypropylene. - 5.UV-C resistant grade (Developed grade)

The UV-C resistant grade has transmittance to UV-C light, which ordinary transparent resins do not, and a certain level of durability against UV-C light, which is extremely damaging to resins.Transmittance measurement results in the UV region by analytical photometer

For High speed communication (Low dielectric) application

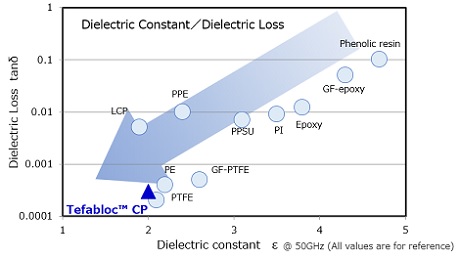

- 1.Excellent low dielectric properties

It has excellent low dielectric properties in terms of dielectric loss and dielectric constant, even in the high frequency range. - 2.Adhesion to dissimilar materials

Tefabloc™ CP adhesion improved grade has high adhesion to various metals (SUS,Al,Cu) and resins(PP,PE,COP,EVOH,PA).

Applications

[Close]

Tefabloc™ CP Application Ideas

For Optical application

- Optical parts

- PV cover materials

- LED sterilization devices, etc.

For High communication application (5G/6G)

- Low-dielectric printed circuit board materials (CCL, FCCL, adhesives, etc.)

- Semiconductor package substrate materials

- Communication cover antennas (radomes), Drone housings, etc.

Grade lineup / Physical properties

[Close]

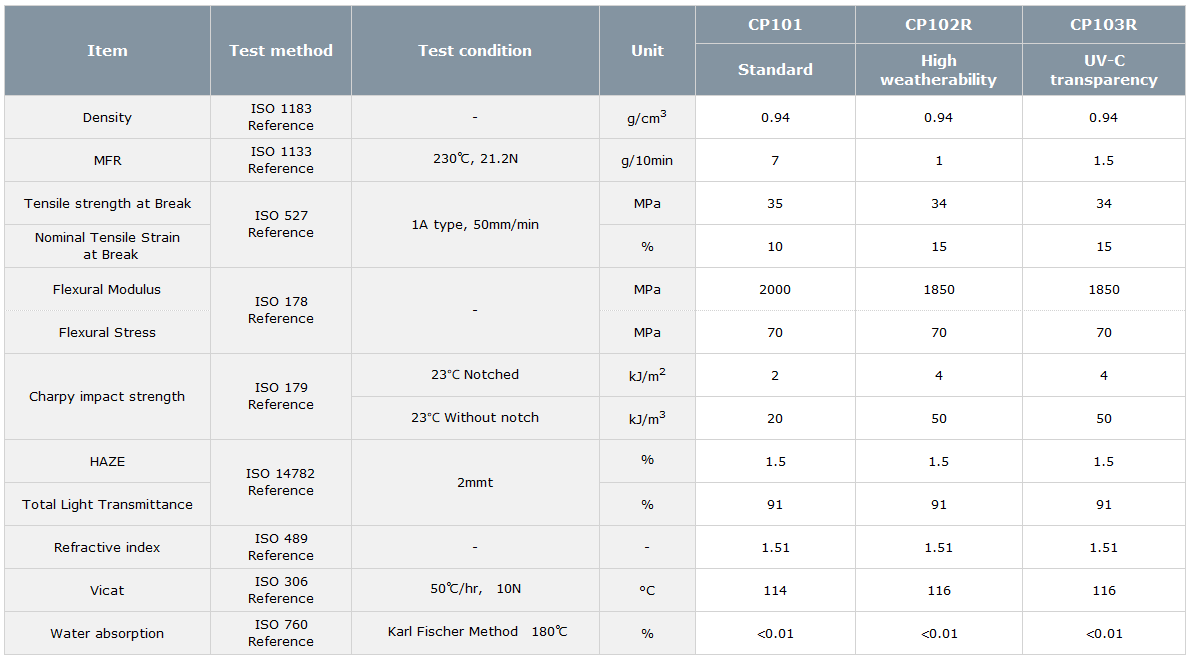

Tefabloc™ CP Optical application

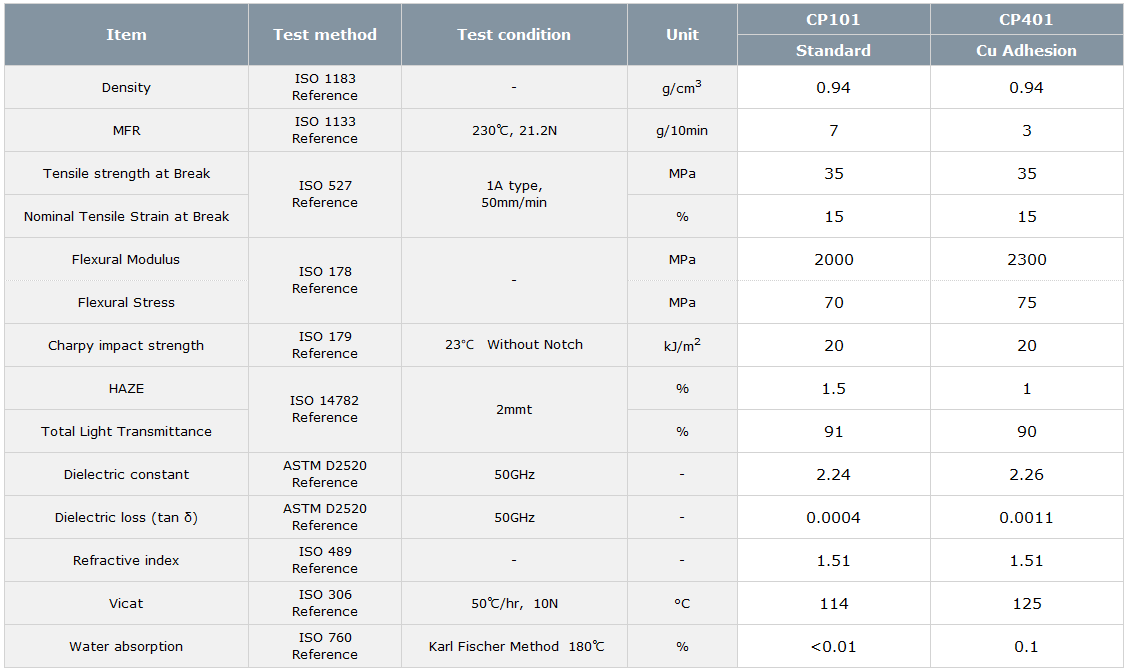

Tefabloc™ CP High speed communication application

Molding conditions

[Close]

| Condition | ||

|---|---|---|

| Tenpereture | Hopper | 180℃(180-240℃) |

| Cylinder | 250℃(230-280℃) | |

| Nozzle | 240℃(220-280℃) | |

| Mold | 80℃ ( 70-100℃) | |

In case of CP101,Cylinder and nozzle temperature is recommended to be 230℃.

| Condition | ||

|---|---|---|

| Temperature | Hopper | 180℃(180-240℃) |

| Cylinder | 250℃(230-280℃) | |

| Die | 240℃(220-280℃) | |

| Roll | 80℃ ( 70-100℃) | |

In case of CP101, Recommended cylinder temperature is 230℃ and die temperature is 220℃.

Inquiries Concerning Products

View the products of Performance Polymers Dept., Mitsubishi Chemical[Open in a new window]