Packaging

324 products.

Filter by business area

[Close]

98 products.

[Close all]

BioPTMG is a polyether polyol manufactured from plant-derived raw materials.

BioPTMG has the same performance as petroleum-derived PTMG as a raw material for polyurethane and polyester resins and has excellent impact, wear and hydrolysis resistance, flexibility at low temperatures, etc. Taking advantage of these characteristics, it can be used in a wide range of fields, from interior and fashion to industrial materials.

- Grades:

- BioPTMG650、BioPTMG1000、BioPTMG2000、BioPTMG3000

- Japan, Chemical Substances Control Law:

- (7)-129

- Japan, Poisonous and Deleterious Substances Control Law:

- Not applicable.

- Japan, Fire Services Law:

- Hazardous Material Class 4 Petroleums No.4 Hazardous Rank III(BioPTMG650)

Combustible Materials, Flammable Solids(BioPTMG1000, 2000, 3000)

PTMG (Poly(tetramethylene ether)glycol / PTMG) is a linear polyether glycol with hydroxyl groups on both ends. As a polyol, it reacts readily with isocyanates (for example MDI, TDI), etc. to make resins with excellent properties.

- Grades:

- PTMG250、PTMG650、PTMG850、PTMG1000、PTMG1300、PTMG1500、PTMG1800、PTMG2000、PTMG3000、PTMG3200(developed grade in mass production)

- Japan, Chemical Substances Control Law:

- METI-No. 7-129

- Japan, Poisonous and Deleterious Substances Control Law:

- Not applicable.

- Japan, Fire Services Law:

- Hazardous Material Class 4 Petroleums No.3 Hazardous Rank III (PTMG250)

Hazardous Material Class 4 Petroleums No.4 Hazardous Rank III (PTMG650,850)

Combustible Materials, Flammable Solids (PTMG1000, 1300, 1500, 1800, 2000, 3000, 3200(developed grade in mass production))

THF (Tetrahydrofuran) is a stable compound with relatively low boiling point and excellent solvency. It is widely-used for dissolution and reaction of various substances. Also it is used as a starting material for the synthesis of poly(tetramethylene ether) glycol (PTMG), etc. Since 1982, Mitsubishi Chemical's Tokai plant has produced high-purity, high-quality THF from butadiene using our proprietary technology.

- EINECS: No. 203-726-8

- Japan, Chemical Substances Control Law: METI-No. 5-53

- Japan, Industrial Safety and Health Law: No. 5-53

- Japan, Industrial Safety and Health Law: Dangerous Goods and Toxic Substances Whose Names Should be Labeled and be Notified Appended Table 2-1278

- Japan, Poisonous and Deleterious Substances Control Law: Not applicable.

- Japan, Fire Services Law: Hazardous Material Class 4 Petroleums No.1 (water-soluble liquid). Hazardous Rank II

- U.N. Class: 3

- U.N. No.: UN2056

NMP (N-Methyl-2-Pyrrolidone) is a polar solvent with outstanding characteristics. It has a wide range of applications because it offers very high solvency, high boiling point, low freezing point, and ease of handling.

- EINECS: No. 212-828-1

- Japan Chemical Substances Control Law: METI-No. 5-113

- Japan, Industrial Safety and Health Law: No. 8-1-1014

- Japan, Industrial Safety and Health Law: Dangerous Goods and Toxic Substances Whose Names Should be Labeled and be Notified Appended Table 2-2108

- Japan, Poisonous and Deleterious Substances Control Law: Not applicable.

- Japan, Fire Services Law: Hazardous material Class 4 Petroleums No.3 (water-soluble liquid).

GBL has a wide range of practical applications because of its low freezing point, high boiling point, and a unique combination of solvent and electrical properties. It has applications as a solvent for special resins, in photography, in batteries, and as an electrolyte. Also a number of derivatives are synthesized from GBL.

- EINECS: No. 202-509-5

- Japan Chemical Substances Control Law: METI-No. 5-3337

- Japan, Industrial Safety and Health Law: No. 5-3337

- Japan, Industrial Safety and Health Law: Dangerous Goods and Toxic Substances Whose Names Should be Labeled and be Notified Appended Table 2-412

- Japan, Poisonous and Deleterious Substances Control Law: Not applicable.

- Japan, Fire Services Law: Hazardous material Class 4 Petroleums No.3 (water-soluble liquid).Aprotic, polar solvent.

12BG (1,2-butanediol) is a branched glycol that has a primary hydroxyl group and a secondary hydroxyl group on adjacent carbon atoms. Mitsubishi Chemical Corporation offers two grades of purity. Both can be reacted with a dicarboxylic acid (e.g., phthalic acid or adipic acid) for use as a polyester polyol or a plasticizer, or reacted with an unsaturated dicarboxylic acid (e.g., maleic anhydride) for use as a raw material for unsaturated polyester resin. The high-purity grade 12BG is suitable for use as a solvent for inks and as a raw material for surfactants.

- EINECS: No. 209-527-2

- Chemical Substance Control Law (CSCL): METI-No. 2-235

- Japan, Industrial Safety and Health Act (ISHA): No. 2-235

- Japan, Poisonous and Deleterious Substances Control Act: Not applicable.

- Japan, Fire Service Act:Hazardous Materials, Category IV—Class III petroleums (water soluble liquids)

14BG (1,4-Butanediol) is a straight chain glycol with hydroxyl groups on both ends. It is used as a raw material for high performance polyester and polyurethane resins as well as for industrial chemicals like tetrahydrofuran and gamma-butyrolactone. Since 1982, Mitsubishi Chemical's Tokai plant has produced high-purity, high-quality 14BG from butadiene using our proprietary technology.

- EINECS: No. 203-786-5

- Japan, Chemical Substances Control Law: METI-No. 2-235

- Japan, Industrial Safety and Health Law: No. 2-235

- Japan, Poisonous and Deleterious Substances Control Law: Not applicable.

- Japan, Fire Services Law: Hazardous material Class 4 Petroleums No.3 (water-soluble liquid).

Polycarbonatediol, BENEBiOL™

[Close]

Polycarbonatediol(PCD) is a linear polycarbonate with hydroxyl groups at both ends. It easily reacts with isocyanate compounds(e.g. MDI, TDI, IPDI, H12MDI), and generates polymers with characteristics such as durability and chemical/hydrolysis resistance. BENEBiOL™ is the biomass-based PCD developed by our proprietary manufacturing technology. Because of “key monomer“ of each grade, polyurethane resins based on BENEBiOL™ will show an outstanding property level with regard to flexibility and chemical/stain resistance for example, in addition to the characteristics of conventional PCD. Besides, your product will be equipped with unique touch and feeling.Biomass-based polycarbonatediol with superior characteristics

Characteristics of polyurethane resins based on BENEBiOL™

non-edible raw material is used for some grades

transparency, stain resistance, chemical resistance, durability, toughness, weather resistance

flexibility, soft feel and touch, high hardness, good fit

FORZEAS™ is a compounding resin developed by Mitsubishi Chemical Corporation using biodegradable and bio-based BioPBS™ and other materials. Each grade has its own unique features and can be used in various applications.

FORZEAS™ can be flexibly formulated depending on customers’ requirements for performance and bio-degradable/bio-based certification.

Biodegradable Polymer, BioPBS™

[Close]

Polybutylene succinate (PBS) is the biodegradable plastic that decomposes into water and carbon dioxide with the microorganism under the soil. PBS has a high heat resistance among the general biodegradablility resin, and PBS has high compatibility with a fiber. Using these goodness, it's possible to achieve the performance which can't be shown by itself as the compound with other resin and material.duct life cycle.

NOVADURAN™ PBT resin has excellent electrical insulation performance, good chemical resistance, moldability. Taking advantage of these characteristics, it has been widely used as a material for automotive ,E&E, and high-performance film applications.

XANTAR™ PC has excellent transparency, impact resistance, flame reistance, heat resistance, electrical properties.

Taking advantage of these characteristics, it has been widely used as a material for automotive ,E&E,

and high-performance extrusion applications.

Pitch Coke

[Close]

Modifiers, METABLEN™

[Close]

METABLEN A type is acrylic-modified PTFE. With small amount of addition, it greatly improves the melt tension that is required in such processing as vacuum molding, foam molding, blow molding and profiling by minimizing increases in melt viscosity without sacrificing the inherent properties of thermoplastics.

METABLEN P type is an acrylic processing aid that offers significant benefits to processors of PVC, ABS, polycarbonate and other thermoplastics. METABLEN P type greatly improves the melt elasticity of thermoplastics and promotes fusion of PVC with addition of low use levels. These products are designed to offer maximum dispersability in much kind of thermoplastics. METABLEN P type is possible to correspond wide range of molecular weight.

METABLEN L type is an acrylic external lubricant that offers exceptional benefits to PVC processors with addition of very low levels. The low use levels mean that there will be scarcely effect on clarity, heat stability, chemical resistance and physical properties. As METABLEN L type introduces low haze contribution and excellent metal release, it is ideal for calendering, blow molding and extrusion applications.

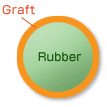

METABLEN C, E, W and S series are core-shell rubber impact modifiers for compounding into thermoplastics. Depending on the desired properties you can select:

C and E series having butadiene-based rubber for excellent impact strength

W series having acrylic based rubber for excellent weatherability

S type having our unique silicone-acrylic hybrid rubber for overall superior impact strength and weatherability

Matting agent, METABLEN™ Type F

[Close]

METABLEN F type acrylic gloss control agent.

This additive is designed to offer maximum dispersibility of thermoplastics. As cross linked particles exist on the surface of final products, the light is dispersed. This structure gives mat appearance to the final product.

METABLEN F type can be also used as a blocking inhibitor for film and sheet.

METABLEN H-602 is an acrylic heat distortion resistant modifier for PVC.

How to Treat, METABLEN™

[Close]

Water-soluble films developed by a specialist in chemical materials

HI-SELON™ is a water-soluble film made from polyvinyl alcohol.

With its excellent heat-sealing property and printability, HI-SELON™ is ideal for use as a packaging materials, but it also provides many other advantages, including high solvent resistance and barrier performance, which are used as materials for packaging of liquid detergent capsules.

PET Bottles

[Close]

Our lineup of PET bottles focuses on meeting the needs of food, seasoning, and alcoholic beverage customers. We are also developing cosmetics, medicine, and industrial applications of our high-barrier bottles originally designed for the food and seasoning industry to preserve freshness and extend shelf life.

Biaxially oriented polystyrene sheets were first commercialized in Japan. Polystyrene tends to crack during the thinning process. As such, biaxially oriented processing is used for this material to give it practical strength. This also gives the material excellent transparency and thermoformability. This material is used for many food packaging applications.

- *Santoclear is a registered trademark of Solutia Inc. and used here under license.

DIAMIRON is a multilayer film combining polyamide, EVOH, polyolefin etc. by our proprietary technology. No chlorinated resin is used. Flat and tube types are available. A wide range of applications as deep drawing and vacuum packaging include food packaging, medical devices, and industrial materials.

DIAMIRON is produced under ISO9001 and FSSC22000-compliant quality control.

Applications

- For food packaging

- For medical device packaging

- For transfusion bags

- For industrial materials

Heat-Shrinkable Film

[Close]

Transparent gas barrier sturucture, SiOx vacuum coated technologies on OPET, OPA. Excels in gas barrier properties as well as aroma substances, chemical resistance and robust processability for printing, bag making process and consistency of oxygen / humidity barrier properties under high temperature and humidity. TECHBARRIER can be widely used for packaging materials in medical, pharmaceutical, industrial and food market.

Bio-based Film, ECOLOJU™

[Close]

We are able to create co-extruded films by using our unique co-extrusion technology to merge multiple resins together in a die.

This high-performance film inherits the properties of each resin used.

We can customize the properties of the film with functionality based on your needs, such as producing a film with high barrier properties.

We constructed a special, clean production environment to produce DIAMIRON as an extremely high-quality primary container. This material is used in such products as transfusion and infusion bags and sterile blister packs for medical supplies.

DIAMIRON is produced at the Azai Plant under ISO 9001 and FSSC 22000-compliant quality control.

Visit the product website for more information.

Applications

- Sterile blister packs for medical supplies

- Transfusion bags

This plastic sheet is used to manufacture press-through packages (PTP) manufactured under Good Manufacturing Practices (GMP) required for medical packaging materials. This material complies with Notification 370 from the Ministry of Labour and Welfare issued in 1959, the Japan Hygienic PVC Association (JHP) standards, and Japan Hygienic Olefin and Styrene Plastics Association PL standards. This material is also registered in the US Food and Drug Administration (FDA) drug master file.

We use various testing equipment such as actual packaging machines used by the pharmaceuticals industry to ensure packaging properties of each material.

We are engaged in development to improve stability of pharmaceuticals manufacturing as well as incorporate the perspective of users including both patients and pharmacists.

Zelas™ CP is a polymer compound products based on amorphous polyolefin with high transparency, which is designed to be suitable as a material for medical devices such as medical vials and syringes that require low adsorption of pharmaceuticals and high hygiene.

Zelas™CP has excellent heat-sealing and dissimilar-material adhesion properties, and can be applied as an inner layer of two-color molding or backing, contributing to improved design of medical device components.

※For industrial applications and when good adhesion to metal is required, we introduce Tefabloc™ CP .

TEFABLOC™ is versatile family of thermoplastic elastomers (TPE). Applies to most of the environments and plastic converting processes.

TEFABLOC™ incorporates several technologies including TPE-S, TPO and TPE-E. Among the large scale of possible properties, some of them are also boosted in process by reactor or dynamic cross-linking.The accurate combination of features leads to tightly satisfy application specifications even the most demanding ones.

VINIKA™ is vinyl based, soft and rigid formulations designed for a wide variety of applications. Fine-tuned properties such as hardness, heat and impact resistance, colour and much more.

A unique tie-layer resin offering excellent adhesive performance to a variety of materials, covering various applications and requirements for automotive, food/non-food packaging, industry and building/construction.

MODIC™ offers two technologies designed to be used as a tie-resin or for peelable purposes:

ZELAS™ are polymers designed for medical applications including R-TPO, specialty TPE compounds and tie layer resins. Specific solutions designed for film, tube and injected components for medical applications.

Soaresin™

[Close]

Soaresin™ is used as a stabilizer or purging agent for extrusion.

Synthetic Paper , YUPO™

[Close]

"YUPO" is a synthetic paper made from polypropylene resin as its primary material. It offers extraordinary beauty, strength and flexibility. YUPO combines the advantages of both paper and plastic film, and thanks to its unique qualities, it is used widely in several fields, including the commercial printing, packaging and communication paper.

Resin compound product

[Close]

We are a one-stop shop for the development and manufacturing of compound products tailored by application and with plastics as their raw materials. The industries we serve are various and include automobiles, home appliances, and health care. We manufacture products to order, tailored to customers’ needs, using proprietary compound technologies.

Terephthalate Plasticizer

[Close]

Phthalate Plasticizers

[Close]

Adipate Plasticizer

[Close]

Other Plasticizers

[Close]

- Product Finder

-