Products

Carbon Fiber Fabrics

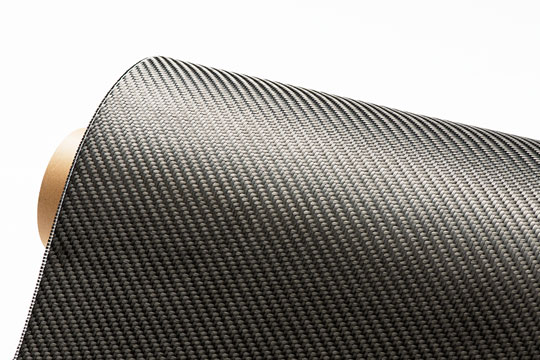

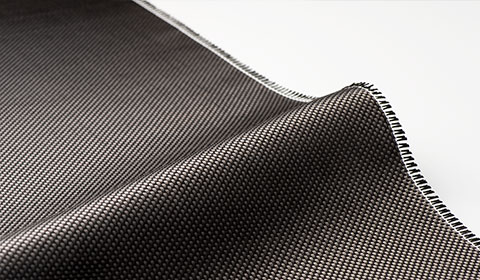

Carbon fiber fabrics have excellent drape properties which make them ideal for 3D shape applications. Due to the outstanding design possibilities they offer, carbon fabrics are also in high demand for applications that require visual appeal. As well as their design potential, carbon fabric materials offer excellent layup efficiency. You can layup a single ply in two directions.

In-page menu

Features

An advantage of Mitsubishi Chemical’s carbon fiber fabrics is that thanks to their drape property, they are easier to shape to a part mold compared to unidirectional UD prepreg.

The appearance of the material can be varied by changing the thickness and weave structure of the carbon fiber used. Thanks to their excellent “designability,” carbon fiber fabrics are used in a wide range of applications from automobile interiors to sports products.

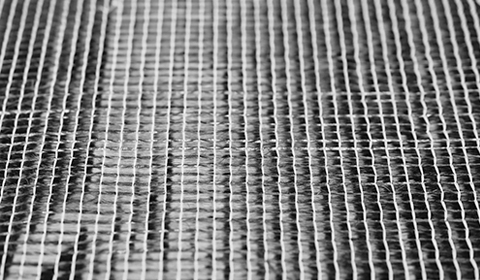

Carbon fiber fabrics are often used for creative design applications, but they can be optimized for a wide range of other applications by changing the weave and basis weight.

By taking advantage of its vertical integration, Mitsubishi Chemical can supply carbon fiber fabrics of the highest quality because of its ability to manufacture optimal carbon fiber materials for specific fabrics.

Applications

Carbon fiber fabrics are used for reinforcement in civil engineering and construction applications, for hand lay-up for small-lot fabrication of aftermarket auto parts, for cloth prepreg for autoclave molding by impregnating them with resin, for internal pressure molding, for PCM molding, and for sheet wrap molding.

Product Lineup

| Product name |

Weave structure |

Tow Warp Weft |

Density (pcs/inch) Warp Weft |

Weight (g/m2) |

Thickness (mm) |

Std. width (mm) |

Std. length (m) |

||

|---|---|---|---|---|---|---|---|---|---|

| TR3110 M | Plain | TR 30S 3L | TR 30S 3L | 12.5 | 12.5 | 200 | 0.23 | 1,000 | 100 |

| TR3523 M | 2/2 twill | TR 30S 3L | TR 30S 3L | 12.5 | 12.5 | 200 | 0.21 | 1,000 | 100 |

| TR6110HM | Plain | TR 50S 6L | TR 50S 6L | 9.0 | 9.0 | 288 | 0.32 | 1,000 | 100 |

| TR6120HM | Plain | TR 50S 6L | TR 50S 6L | 11.0 | 11.0 | 350 | 0.39 | 1,000 | 100 |

| TRK101 M | Plain | TR 50S12L | TR 50S12L | 6.3 | 6.3 | 400 | 0.46 | 1,000 | 50 |

| TRK510 M | 2/2 twill | TR 50S12L | TR 50S12L | 10.0 | 10.0 | 646 | 0.57 | 1,000 | 50 |

| Product name |

Weave structure |

Tow Warp Weft |

Density (pcs/inch) Warp Weft |

Weight (g/m2) |

Thickness (mm) |

Std. width (mm) |

Std. length (m) |

||

|---|---|---|---|---|---|---|---|---|---|

| TR3160TMS | Plain | TR 30S 3L Aramid fiber |

TR 30S 3L Aramid fiber |

6.0 6.0 |

6.0 6.0 |

180 | 0.24 | 1,000 | 100 |

| Product name |

Weave structure |

Tow Warp Weft |

Density (pcs/inch) Warp Weft |

Weight (g/m2) |

Thickness (mm) |

Std. width (mm) |

Std. length (m) |

||

|---|---|---|---|---|---|---|---|---|---|

| TRK979PQRW | Plain | TR 50D 12L | Glass fiber Nylon (polyamide) fiber |

6.6 | 8.0 | 212 | 0.25 | 500 | 50 |

| TRK976PQRW | Plain | TR 50D 12L | Glass fiber Nylon (polyamide) fiber |

9.9 | 8.0 | 317 | 0.32 | 500 | 50 |

| Product name |

Weave structure |

Tow Warp Weft |

Density (pcs/inch) Warp Weft |

Weight (g/m2) |

Thickness (mm) |

Std. width (mm) |

Std. length (m) |

||

|---|---|---|---|---|---|---|---|---|---|

| F637400 | Plain | K63712 | Glass fiber | 5.0 | 12.0 | 400 | 0.20 | 330 | 50 |

The figures in this table are typical and do not imply any guarantee.

The weights of standard and hybrid fabrics include sizing agent. On the other hand, the weight of unidirectional fabrics excludes the weft and sizing agent.