Polymers / Resins / High Performance Chemicals

324 products.

Filter by Application

[Close]

170 products.

[Close all]

DURABIO™ is a bio-based polycarbonate resin derived mainly from plant-based isosorbide. Compared with conventional polycarbonate resin (hereafter abbreviated PC resin) made from bisphenol A (hereafter abbreviated BPA), DURABIO™ features high transparency, excellent optical properties, and outstanding scratch resistance. Its puncture impact behaviour are comparable to those for PC resin. DURABIO™ is a plant-derived polymer but is not biodegradable. It has excellent durability, making possible its deployment in a wide variety of applications such as for optical ・energy related components, a substitute for high-performance glass components, as well as for electronic equipment ・ automotive housings ・ interior and exterior decor.

BioPTMG is a polyether polyol manufactured from plant-derived raw materials.

BioPTMG has the same performance as petroleum-derived PTMG as a raw material for polyurethane and polyester resins and has excellent impact, wear and hydrolysis resistance, flexibility at low temperatures, etc. Taking advantage of these characteristics, it can be used in a wide range of fields, from interior and fashion to industrial materials.

- Grades:

- BioPTMG650、BioPTMG1000、BioPTMG2000、BioPTMG3000

- Japan, Chemical Substances Control Law:

- (7)-129

- Japan, Poisonous and Deleterious Substances Control Law:

- Not applicable.

- Japan, Fire Services Law:

- Hazardous Material Class 4 Petroleums No.4 Hazardous Rank III(BioPTMG650)

Combustible Materials, Flammable Solids(BioPTMG1000, 2000, 3000)

PTMG (Poly(tetramethylene ether)glycol / PTMG) is a linear polyether glycol with hydroxyl groups on both ends. As a polyol, it reacts readily with isocyanates (for example MDI, TDI), etc. to make resins with excellent properties.

- Grades:

- PTMG250、PTMG650、PTMG850、PTMG1000、PTMG1300、PTMG1500、PTMG1800、PTMG2000、PTMG3000、PTMG3200(developed grade in mass production)

- Japan, Chemical Substances Control Law:

- METI-No. 7-129

- Japan, Poisonous and Deleterious Substances Control Law:

- Not applicable.

- Japan, Fire Services Law:

- Hazardous Material Class 4 Petroleums No.3 Hazardous Rank III (PTMG250)

Hazardous Material Class 4 Petroleums No.4 Hazardous Rank III (PTMG650,850)

Combustible Materials, Flammable Solids (PTMG1000, 1300, 1500, 1800, 2000, 3000, 3200(developed grade in mass production))

Maleic anhydride is produced by oxidation of benzene or a C4 hydrocarbon such as butane in the presence of a vanadium oxide catalyst. Maleic anhydride can be converted to maleic acid by hydrolysis and to esters by alcoholysis.

- EINECS: No. 203-571-6

- Japan, Chemical Substances Control Law: METI-No. 2-1101

- Japan, Industrial Safety and Health Law: Dangerous Goods and Toxic Substances Whose Names Should be Labeled and be Notified Appended Table 2-1978

- Japan, Poisonous and Deleterious Substances Control Law: Not applicable.

- Japan, Fire Services Law: Not applicable.

THF (Tetrahydrofuran) is a stable compound with relatively low boiling point and excellent solvency. It is widely-used for dissolution and reaction of various substances. Also it is used as a starting material for the synthesis of poly(tetramethylene ether) glycol (PTMG), etc. Since 1982, Mitsubishi Chemical's Tokai plant has produced high-purity, high-quality THF from butadiene using our proprietary technology.

- EINECS: No. 203-726-8

- Japan, Chemical Substances Control Law: METI-No. 5-53

- Japan, Industrial Safety and Health Law: No. 5-53

- Japan, Industrial Safety and Health Law: Dangerous Goods and Toxic Substances Whose Names Should be Labeled and be Notified Appended Table 2-1278

- Japan, Poisonous and Deleterious Substances Control Law: Not applicable.

- Japan, Fire Services Law: Hazardous Material Class 4 Petroleums No.1 (water-soluble liquid). Hazardous Rank II

- U.N. Class: 3

- U.N. No.: UN2056

NMP (N-Methyl-2-Pyrrolidone) is a polar solvent with outstanding characteristics. It has a wide range of applications because it offers very high solvency, high boiling point, low freezing point, and ease of handling.

- EINECS: No. 212-828-1

- Japan Chemical Substances Control Law: METI-No. 5-113

- Japan, Industrial Safety and Health Law: No. 8-1-1014

- Japan, Industrial Safety and Health Law: Dangerous Goods and Toxic Substances Whose Names Should be Labeled and be Notified Appended Table 2-2108

- Japan, Poisonous and Deleterious Substances Control Law: Not applicable.

- Japan, Fire Services Law: Hazardous material Class 4 Petroleums No.3 (water-soluble liquid).

GBL has a wide range of practical applications because of its low freezing point, high boiling point, and a unique combination of solvent and electrical properties. It has applications as a solvent for special resins, in photography, in batteries, and as an electrolyte. Also a number of derivatives are synthesized from GBL.

- EINECS: No. 202-509-5

- Japan Chemical Substances Control Law: METI-No. 5-3337

- Japan, Industrial Safety and Health Law: No. 5-3337

- Japan, Industrial Safety and Health Law: Dangerous Goods and Toxic Substances Whose Names Should be Labeled and be Notified Appended Table 2-412

- Japan, Poisonous and Deleterious Substances Control Law: Not applicable.

- Japan, Fire Services Law: Hazardous material Class 4 Petroleums No.3 (water-soluble liquid).Aprotic, polar solvent.

12BG (1,2-butanediol) is a branched glycol that has a primary hydroxyl group and a secondary hydroxyl group on adjacent carbon atoms. Mitsubishi Chemical Corporation offers two grades of purity. Both can be reacted with a dicarboxylic acid (e.g., phthalic acid or adipic acid) for use as a polyester polyol or a plasticizer, or reacted with an unsaturated dicarboxylic acid (e.g., maleic anhydride) for use as a raw material for unsaturated polyester resin. The high-purity grade 12BG is suitable for use as a solvent for inks and as a raw material for surfactants.

- EINECS: No. 209-527-2

- Chemical Substance Control Law (CSCL): METI-No. 2-235

- Japan, Industrial Safety and Health Act (ISHA): No. 2-235

- Japan, Poisonous and Deleterious Substances Control Act: Not applicable.

- Japan, Fire Service Act:Hazardous Materials, Category IV—Class III petroleums (water soluble liquids)

14BG (1,4-Butanediol) is a straight chain glycol with hydroxyl groups on both ends. It is used as a raw material for high performance polyester and polyurethane resins as well as for industrial chemicals like tetrahydrofuran and gamma-butyrolactone. Since 1982, Mitsubishi Chemical's Tokai plant has produced high-purity, high-quality 14BG from butadiene using our proprietary technology.

- EINECS: No. 203-786-5

- Japan, Chemical Substances Control Law: METI-No. 2-235

- Japan, Industrial Safety and Health Law: No. 2-235

- Japan, Poisonous and Deleterious Substances Control Law: Not applicable.

- Japan, Fire Services Law: Hazardous material Class 4 Petroleums No.3 (water-soluble liquid).

Polycarbonatediol, BENEBiOL™

[Close]

Polycarbonatediol(PCD) is a linear polycarbonate with hydroxyl groups at both ends. It easily reacts with isocyanate compounds(e.g. MDI, TDI, IPDI, H12MDI), and generates polymers with characteristics such as durability and chemical/hydrolysis resistance. BENEBiOL™ is the biomass-based PCD developed by our proprietary manufacturing technology. Because of “key monomer“ of each grade, polyurethane resins based on BENEBiOL™ will show an outstanding property level with regard to flexibility and chemical/stain resistance for example, in addition to the characteristics of conventional PCD. Besides, your product will be equipped with unique touch and feeling.Biomass-based polycarbonatediol with superior characteristics

Characteristics of polyurethane resins based on BENEBiOL™

non-edible raw material is used for some grades

transparency, stain resistance, chemical resistance, durability, toughness, weather resistance

flexibility, soft feel and touch, high hardness, good fit

FORZEAS™ is a compounding resin developed by Mitsubishi Chemical Corporation using biodegradable and bio-based BioPBS™ and other materials. Each grade has its own unique features and can be used in various applications.

FORZEAS™ can be flexibly formulated depending on customers’ requirements for performance and bio-degradable/bio-based certification.

Biodegradable Polymer, BioPBS™

[Close]

Polybutylene succinate (PBS) is the biodegradable plastic that decomposes into water and carbon dioxide with the microorganism under the soil. PBS has a high heat resistance among the general biodegradablility resin, and PBS has high compatibility with a fiber. Using these goodness, it's possible to achieve the performance which can't be shown by itself as the compound with other resin and material.duct life cycle.

NOVADURAN™ PBT resin has excellent electrical insulation performance, good chemical resistance, moldability. Taking advantage of these characteristics, it has been widely used as a material for automotive ,E&E, and high-performance film applications.

XANTAR™ PC has excellent transparency, impact resistance, flame reistance, heat resistance, electrical properties.

Taking advantage of these characteristics, it has been widely used as a material for automotive ,E&E,

and high-performance extrusion applications.

Acrylic Sheet, SHINKOLITE™

[Close]

SHINKOLITE™ is the registered trade name of Mitsubishi Chemical's continuous cast acrylic sheet. Known as acrylic resin, this material has excellent weather resistance, stainability, and processability properties, and so is used in many applications such as signage, display, large water tanks, LCDs, and light guide plates. We will continue to leverage these properties and develop new products such as the flame-retardant and impact-resistant grades of SHINKOLITE. It is our goal to provide environmentally friendly products that make society safer and help people to have more comfortable and prosperous lives.

Methacrylic resin is an extremely high-quality material and is sometimes referred to as the "queen of plastics" due to having the highest degree of transparency among plastics as well as other excellent properties including weather resistance, chemical resistance, hardness, and attractiveness. This material is used in many products used in everyday life such as automobiles, building materials, household appliances, and optical goods.

Rod Lens Arrays, Rodscope™

[Close]

ACRYKING™ is a coating that is cured by UV irradiation. Valued for its environmental friendliness, it is used for automotive headlamps.

MKC™ Silicate is an oligomer formed by the partial hydrolysis of tetramethoxysilane. As an additive in paints, it produces a hydrophilic surface that is highly stain-resistant with the self-cleaning effect.

- Emulsion Type Resin (HX,LX,NT series)

-

Emulsion type resin is a water-based resin produced by emulsion polymerization. Our product line-up includes acrylic resins, acrylic-silicone resins, acrylic-urethane resins, acrylic-olefin resins, and organic-inorganic hybrid resins, which meets customers' requirements in various applications, mainly for paints.

SURFLEN™ is a modified polyolefin elastomer with improved weather resistant adhesion and low temperature flexibility/shock resistance. It was developed uniquely in our company as a primer for coating non-polar olefin resin surfaces such as polypropylene (PP) and polyethylene (PE). SURFLEN™ binds well not only to polyolefin but also to various plastics and metal materials, and can be used in a wide range of applications including paints, print and adhesive primers for these materials.

Antistatic Agent, SAFTOMER™

[Close]

SAFTOMER™ is an ionic acrylic coating material used for surface coating as an antistatic agent. It is made of a polymer that yields a lasting antistatic property.

UV Curable Coatings, DIABEAM™

[Close]

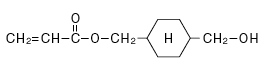

UV/EB Curable Resin, Yupimer™ UV

[Close]

Yupimer™ UV series are functional hard coating materials developed by Mitsubishi Chemical Co., with distinctive technologies. They have various functions such as antistatic, anti-fingerprint, slipperiness, and moldable.

- Acrylic Pressure Sensitive Adhesives (PSA)

―To Create New Value for Your Needs -

COPONYL is pressure sensitive adhesive(PSA) resin made mainly from acrylic acid ester using such solvents as ethyl acetate and toluene. The demand for PSA is increasing and expanding: they are now used in a wide range of applications including labels, single/double-sided tapes, foams, and electronic applications such as protective masking films.

- SHIKOH ――UV Curable Resin from Mitsubishi Chemical

-

UV curable resin is garnering wide spread attention for its low-polluting, energy-saving properties and high productivity.

Mitsubishi Chemical offers a wide lineup of such resin under the SHIKOH brand name, with a special emphasis on urethane acrylate oligomer.

In addition to hard coating application, SHIKOH is suitable for use in a wide range of applications. Mitsubishi Chemical's SHIKOH holds the key to the future of ultraviolet curable resin.

Acrylic Beads Resin

Acrylic beads resin is a solid bead-shaped methacrylic resin produced by suspension polymerization. Being solid and non-hazardous, customers can choose their own solvents, and it is easy to transport and store. We have manufacturing sites and sales networks around the world, enabling us to supply globally. We provide free samples from 500g for customers' initial study.

Acrylic Resins for Coating

[Close]

- We maximizes the potential of acrylic resin as a coating material

-

Based on the basic features of acrylic resin such as "transparency" and "high weather resistance," Mitsubishi Chemical contributes to solving customers' problems with its abundant product lineup and prompt and comprehensive customer service.

Utilizing our own methacrylate monomers, we produce and sell globally competitive and stable quality products.

Our resins are being used in a wide range of applications such as paints, inks, and adhesives.

Acrylic Powder Resin

Acrylic powder resin is a fine powder resin made by spray-drying acrylic resin emulsion on particles. Core/shell type structural design is possible, and we are developing products that can demonstrate their characteristics in various applications. It shows good solubility in various solvents and liquid resins.

- From Current Needs into the Future

-

Nichigo-POLYESTER recreates the fields of high-tech adhesives, coating binders, and resin modification.

Nichigo-POLYESTER displays excellent adhesive performance with plastic films and moldings including PET, polycarbonate, and vinyl chloride, and metals including aluminum and copper. Used in tandem with isocyanate, melamine, and epoxy resins and other hardening agents, they offer increased heat resistance, solvent resistance, and hardness. Mitsubishi Chemical offers the optimum line-up for all customer needs, including amorphous solvent-soluble, crystalline hot melt, water-soluble, and special types.

Developed to respond to the increasing trends toward compactness and high speed of printers, this product has attracted considerable attention. We intend to develop into the field of color toners to expand the potential market further.

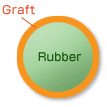

Modifiers, METABLEN™

[Close]

METABLEN A type is acrylic-modified PTFE. With small amount of addition, it greatly improves the melt tension that is required in such processing as vacuum molding, foam molding, blow molding and profiling by minimizing increases in melt viscosity without sacrificing the inherent properties of thermoplastics.

METABLEN P type is an acrylic processing aid that offers significant benefits to processors of PVC, ABS, polycarbonate and other thermoplastics. METABLEN P type greatly improves the melt elasticity of thermoplastics and promotes fusion of PVC with addition of low use levels. These products are designed to offer maximum dispersability in much kind of thermoplastics. METABLEN P type is possible to correspond wide range of molecular weight.

METABLEN L type is an acrylic external lubricant that offers exceptional benefits to PVC processors with addition of very low levels. The low use levels mean that there will be scarcely effect on clarity, heat stability, chemical resistance and physical properties. As METABLEN L type introduces low haze contribution and excellent metal release, it is ideal for calendering, blow molding and extrusion applications.

METABLEN C, E, W and S series are core-shell rubber impact modifiers for compounding into thermoplastics. Depending on the desired properties you can select:

C and E series having butadiene-based rubber for excellent impact strength

W series having acrylic based rubber for excellent weatherability

S type having our unique silicone-acrylic hybrid rubber for overall superior impact strength and weatherability

Matting agent, METABLEN™ Type F

[Close]

METABLEN F type acrylic gloss control agent.

This additive is designed to offer maximum dispersibility of thermoplastics. As cross linked particles exist on the surface of final products, the light is dispersed. This structure gives mat appearance to the final product.

METABLEN F type can be also used as a blocking inhibitor for film and sheet.

METABLEN H-602 is an acrylic heat distortion resistant modifier for PVC.

How to Treat, METABLEN™

[Close]

DIACARNA™ is a synthetic wax copolymer of α-olefin and maleic anhydride. Applications include as an compounding additive for resin mold lubricant and release agent, compatibilizer and as a binder for thermal transfer inks.

TAIC WH-60 is the improved product made by impregnation of TAIC (Triallylisocyanurate)on to White Carbon.

TAIC WH-60 is outstanding and new type crosslinking agent for Polyolefines including Polyethylene, Polypropylene, Chlorinated polyethylene, EVA, EPDM, etc.

TAIC WH-60 is powdered from crosslinking agent and processes all of thecharacteristic of TAIC and much more improved qualities over TAIC as follows :

- 1)Easier handling in processing

- 2)Better dispersion into Polyolefines in kneading

- TSCA:

- 1025-15-6(Triallylisocyanurate)

- EINECS:

- 213-834-7(Triallylisocyanurate)

YOSHINOX BB is a phenolic antioxidant used as a resin additive or resin chemical.

YOSHINOX 425 (2,2'-Methylenebis(6-tert-butyl-4-ethylphenol)) is a phenolic antioxidant used as a resin additive or resin chemical.

C/C composite, C/SiC composite

[Close]

C/C (carbon fiber reinforced carbon) composites are made of carbon matrix reinforced with carbon fiber, and have high strength, high elasticity, high toughness, and ultra-high heat resistance, and can be used at temperatures above 1,000ºC.

C/SiC, also known as ceramic matrix composite (CMC), is a composite material with a ceramic matrix, and our CMC is reinforced with carbon fiber. It has higher strength and elasticity than C/C composite, and can be used in a wider variety of applications.

Golf Shaft

[Close]

Golf Shafts Product Page - Carbon fiber has been developed into a leading material in the field of sports equipment, due to its excellent design flexibility and its superior heat and impact resistance. The share of CF shafts in the golf shaft market has been growing for many years, driven especially by strong demand for lightweights, and it continues to grow.

(CF shafts are produced by wrapping sheets of carbon fiber impregnated with epoxy resin, known as “prepregs,” around a metal core, and then curing at high temperature.)

Carbon fiber composite materials, also known as carbon fiber reinforced plastics (CFRP), are composite materials made of carbon fibers and resin (mainly epoxy resin).

As light, strong, and hard materials, they are used in wide range of applications such as sporting goods, industrial, aircraft and automobile components. By selecting suitable resin, it is possible to add features like heat resistance, impact resistance, and flame retardant, and thus provide superior characteristics not found in conventional metals and ceramics to enable a reduction in the weight of parts, give freer design.

Carbon Fiber Pellets

[Close]

Carbon fiber pellets are thermoplastic molding materials created by blending carbon fiber with various resins to achieve performance that is superior to conventional reinforced resins. Advanced physical properties can be achieved by combining different base resins and carbon fibers, according to the specific application.

This photosensitive polymer for photo resists is used during the formation of semiconductor circuits.

This material is designed to satisfy strict quality requirements, such as high purity and low metal content, associated with the miniaturization of circuit patterns.

Our services include polymer design, prototyping, and mass production.

This antistatic agent is used to prevent electrons from accumulating on the resist surface during electron beam lithography.

This material is used in advanced photomask manufacturing to help prevent charge-up failures.

Antistatic Agent, aquaPASS™

[Close]

This water-based antistatic agent is derived from polyaniline-based, water-soluble electroconductive polymers.

This agent prevents particles from adhering due to static electricity when used as a coating on films and plastic substrates.

Use of this agent enables the production of thin films with excellent antistatic performance, transparency, and minimal humidity dependency.

Epoxy Resin, jER™

[Close]

Regarding the jER™ (formerly Epikote™ *) epoxy resin, Mitsubishi Chemical is prepared to support our customers' needs quickly and flexibly. Our production is extremely fast because we have accumulated many years of research with epoxy products. Our manufacturing, sales, research, and development are tightly integrated to enable rapid response to the challenges our customers face. (*Epikote™ is a trademark of Hexion Inc. )

jERCURE™ curing agents for epoxy resins are an abundant set of curing agents that cover the full range from low to high curing temperature with functional groups ranging from amine, mercaptan, and phenol to Lewis acid complex compounds. A curing agent can be chosen from this set to fit the application. There are water-based curing agents for water-based epoxy resins, too.

Diluent(reactive), YED

[Close]

YED is reactive diluents for an epoxy resin that provides low viscosity without compromising the resin's special characteristics.

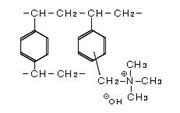

An amino functional group is incorporated into the anion exchange resin enabling the exchange of anions like the Cl- ion and the SO4-- ion. Strongly basic anion exchange resins and weakly basic anion exchange resins can be defined according to the basic strength of the amino functional group.

The ion exchange resin that has a quaternary ammonium group is strongly alkaline and dissociates just like NaOH and KOH. Therefore it is called a strongly basic anion exchange resin.

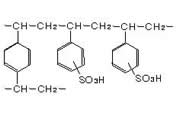

The strongly acidic cation exchange resins are bead-like products which have a sulfonic acid group in the cross-linked styrene frame. They can be used across the full pH range (0-14), and are relatively stable to temperature, even withstanding high temperatures of 100-120℃. They are used in a wide variety of fields including water purification, water softening, wastewater treatment, purification of pharmaceuticals and food, and catalysis.

Acrylic Film, ACRYPLEN™

[Close]

We have been engaged since 1975 in the development, manufacture, and sale of acrylic (PMMA) films through a combination of our unique in-house polymer design and thin film forming technologies.

ACRYPLEN (acrylic film) features the excellent transparency, weatherability, suitability for heat-molding and lamination processing. In addition, it has outstanding UV protection, making it ideal for use as a construction material, a paint-alternative, and a retro reflective material, as well as for a wide range of applications in the field of optical engineering.

Mitsubishi Chemical is a pioneer in the development of acrylic films, and the Company’s lineup encompasses products with a wide variety of thicknesses, widths, and differing degrees of flexibility/rigidity.

Zelas™ CP is a polymer compound products based on amorphous polyolefin with high transparency, which is designed to be suitable as a material for medical devices such as medical vials and syringes that require low adsorption of pharmaceuticals and high hygiene.

Zelas™CP has excellent heat-sealing and dissimilar-material adhesion properties, and can be applied as an inner layer of two-color molding or backing, contributing to improved design of medical device components.

※For industrial applications and when good adhesion to metal is required, we introduce Tefabloc™ CP .

Tefabloc™ CP is based on amorphous polyolefins, which not only have high transparency, but also have unique properties not found in other cyclic olefins (COP/COC).

We are developing products for optical applications such as solar panel cover materials utilizing its transparency, and for high-speed communication applications such as 5G and 6G utilizing its low dielectric properties, and can also design products according to customer requirements.

※For medical application, we introduce Zelas™ CP .

TREXPRENE™ TPV (Thermoplastic Vulcanizate) is a heat stabilized, vulcanized PP / EPDM product. Globally available for a wide range of applications and approved to a variety of Automotive Specifications.

TEFABLOC™ is versatile family of thermoplastic elastomers (TPE). Applies to most of the environments and plastic converting processes.

TEFABLOC™ incorporates several technologies including TPE-S, TPO and TPE-E. Among the large scale of possible properties, some of them are also boosted in process by reactor or dynamic cross-linking.The accurate combination of features leads to tightly satisfy application specifications even the most demanding ones.

Halogen Free Flame Retardant (HFFR) olefin based compound with low smoke solutions (LSZH)

VINIKA™ is vinyl based, soft and rigid formulations designed for a wide variety of applications. Fine-tuned properties such as hardness, heat and impact resistance, colour and much more.

A unique tie-layer resin offering excellent adhesive performance to a variety of materials, covering various applications and requirements for automotive, food/non-food packaging, industry and building/construction.

MODIC™ offers two technologies designed to be used as a tie-resin or for peelable purposes:

ZELAS™ are polymers designed for medical applications including R-TPO, specialty TPE compounds and tie layer resins. Specific solutions designed for film, tube and injected components for medical applications.

Sunprene™ is high performance flexible PVC-P compounds for demanding environments with outstanding aesthetics.

Soarlite is the trade name of ethylene-vinyl alcohol copolymer for injection molding application as engineering plastics.

Soaresin™

[Close]

Soaresin™ is used as a stabilizer or purging agent for extrusion.

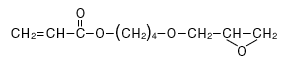

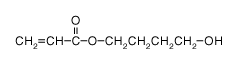

4-HYDROXYBUTYL ACRYLATE, 4HBA

[Close]

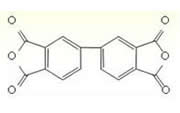

BPDA (3,3',4,4'-Biphenyltetracarboxylic dianhydride) is a raw material for the polyimide resin component of one of the super-engineering plastics. It is used for many important information and electronic technology products such as mobile phones and copying machines.

EINECS: No.219-342-9

Japan Chemical Mfg. Reg.: No.4-833

Japan Poisonous and Deleterious Substances Control Law: Not applicable

Fire Services Law: Not applicable

Terephthalate Plasticizer

[Close]

Phthalate Plasticizers

[Close]

Adipate Plasticizer

[Close]

Other Plasticizers

[Close]

- Product Finder

-