Products

Carbon Fiber Pellets

Carbon fiber pellets are thermoplastic molding materials created by blending carbon fiber with various resins to achieve performance that is superior to conventional reinforced resins. Advanced physical properties can be achieved by combining different base resins and carbon fibers, according to the specific application.

In-page menu

Features

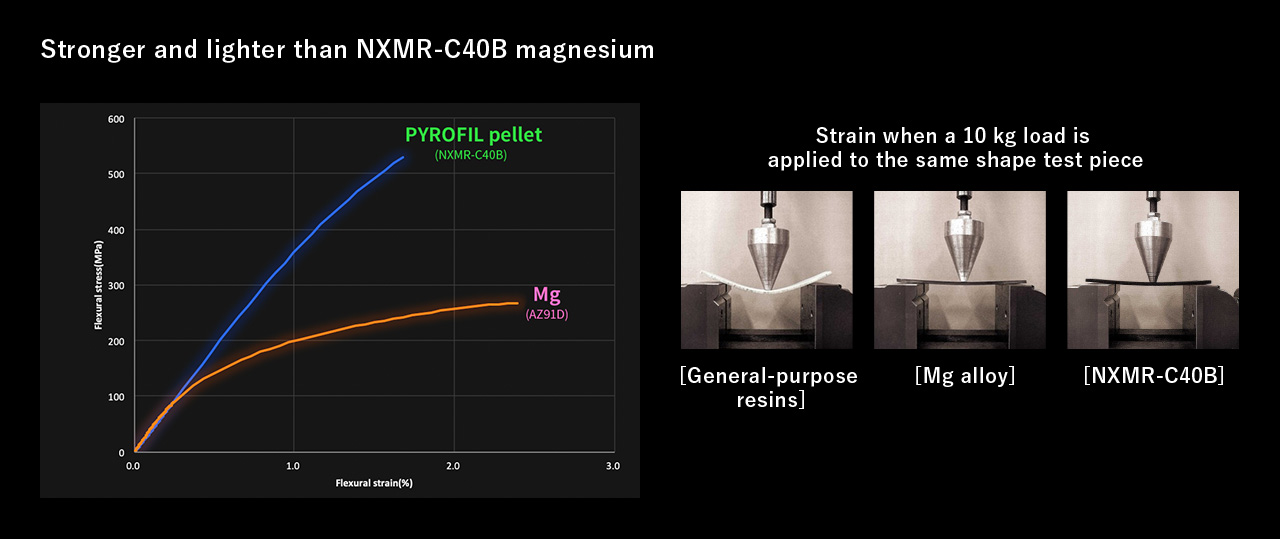

Mitsubishi Chemical’s carbon fiber pellets (PYROFIL™ pellets) are thermoplastic molding materials made by blending our PAN-based carbon fiber (PYROFIL™) and pitch-based carbon fiber (DIALEAD™) with various resins to achieve performance that is superior to conventional reinforced resins.

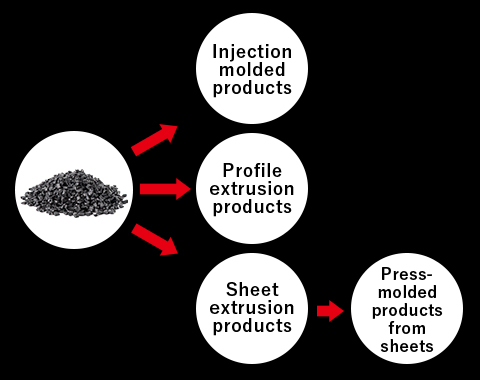

The use of thermoplastic resins makes processing easy (injection, profile extrusion, sheet/press processing, and other methods). This also enables a high degree of design freedom and complex processing.

Substituting these materials for fiberglass-reinforced thermoplastics and metals can significantly reduce the weight of products.

These materials boast excellent antistatic protection and electromagnetic shielding properties. In fact, they do not require any electromagnetic shielding treatment (no need for vapor deposition or sheet metal means lower total cost).

We offer a wide range of thermoplastic resins (e.g., PP, PA, PPS, PC, ABS), allowing you to select the optimal resin for your desired specifications (e.g., heat-resistance, chemical resistance).

Product Lineup

Product Lineup

| Type | Features |

|---|---|

| PA66 Series | Very high strength |

| PA-MXD6 Series | Very high rigidity and strength |

| PC Series | High strength and excellent dimensional stability |

| ABS Series | Excellent dimensional stability and good moldability |

| PP Series | Low specific gravity makes it ideal for weight-saving |

| PBT Series | Excellent strength and good moldability |

| POM series | Good wear resistance |

| PPS Series | Excellent heat-resistance, high elastic modulus, and flame resistance |

| m-PPE Series | Excellent dimensional stability |