Products

Carbon Fiber Tow

(Continuous fiber)

Carbon fiber is a high-strength and high-elastic modulus material, yet its specific gravity is only one-fourth that of iron. It, therefore, enables high strength, high rigidity, and weight-saving in a wide variety of applications.

Carbon fiber tow, made of bundles of untwisted filaments, is the essential material in our carbon fiber product line.

In-page menu

Features

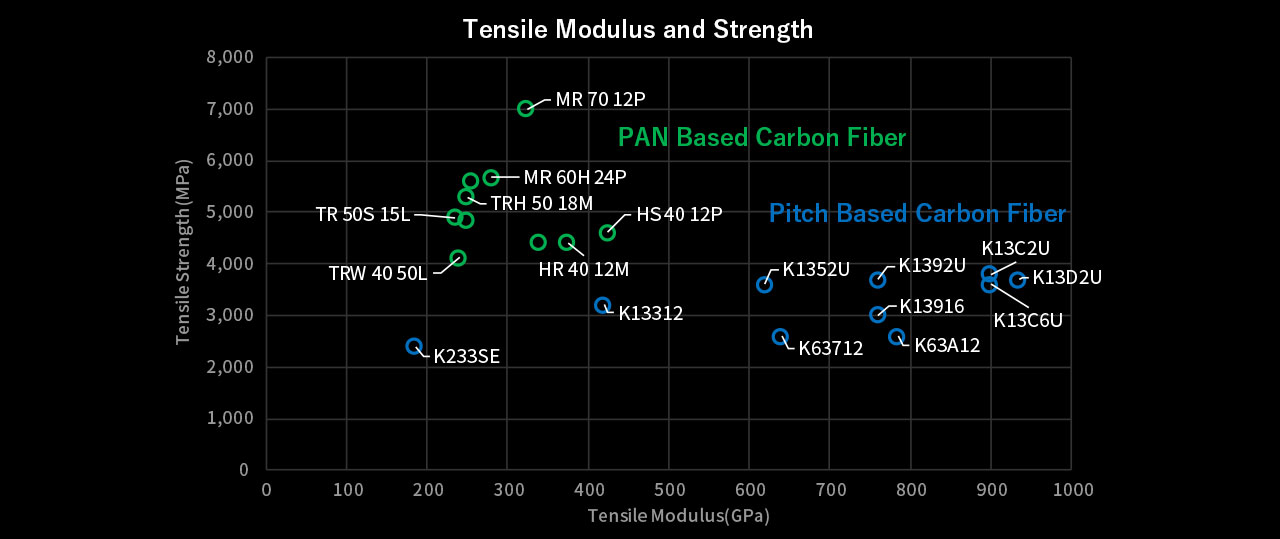

Mitsubishi Chemical manufactures both PAN-based and pitch-based carbon fiber materials.

Thanks to our unique ability to manufacture carbon fiber from two basic raw materials, PAN and pitch, in comprehensive, streamlined production systems, we offer a variety of high-quality carbon fiber tow, including ultra-high strength (MR70 12P) and ultra-high modulus (K13D2U) materials.

The raw material fiber (precursor) for PAN-based carbon fiber is made using polyacrylonitrile (PAN) as a raw material. The raw PAN is polymerized utilizing Mitsubishi Chemical’s unique expertise in polymer synthesis and polymer processing technologies and then spun.

The raw material fiber for pitch-based carbon fiber is produced by obtaining coal tar pitch from coal utilizing Mitsubishi Chemical’s longstanding knowledge of coal chemistry, processing the pitch using an original process, and finally spinning the pitch.

Carbon fiber tow is produced by carbonizing these raw fibers in a highly controlled environment.

Mitsubishi Chemical has also acquired quality management system certification (JISQ9100) in the field of aviation, aerospace, and defense, and it constantly strives to improve its quality management system further.

Applications

Carbon fiber tow is processed into various forms and combined with matrix resin to use like carbon fiber reinforced plastics (CFRP). Products made from CFRP exhibit high-strength, high-elastic modulus, and lightweight, a combination of properties unique to carbon fiber.

For more information on carbon fiber molding methods, click here.

For intermediate material products processed from carbon fiber tow, please click here.

Carbon fiber tow can be used for any applications in which strength, rigidity, and lightweight are required, such as automobiles, wind power generation, aircraft, and sporting goods.

Carbon Fiber

Intermediate Materials

Product Lineup

| Fiber type | Filament count |

Filament dia. (µm) |

Tensile modulus (GPa) |

Tensile strength (GPa) |

Yield (mg/m) |

Density (g/cm3) |

|---|---|---|---|---|---|---|

| TR 30S 3L | 3,000 | 7 | 235 | 4.12 | 200 | 1.79 |

| TR 50S 6L | 6,000 | 7 | 235 | 4.90 | 400 | 1.82 |

| TR 50S12L | 12,000 | 7 | 235 | 4.90 | 800 | 1.82 |

| TR 50S15L | 15,000 | 7 | 235 | 4.90 | 1,000 | 1.82 |

| TR 50D12L | 12,000 | 7 | 235 | 5.00 | 800 | 1.82 |

| TRH50 18M | 18,000 | 6 | 250 | 5.30 | 1,000 | 1.82 |

| TRH50 30M | 30,000 | 6 | 255 | 5.60 | 1,670 | 1.82 |

| TRH50 60M | 60,000 | 6 | 250 | 4.83 | 3,200 | 1.81 |

| TRW40 50L | 50,000 | 7 | 240 | 4.12 | 3,750 | 1.81 |

| MR 60H 24P | 24,000 | 5 | 280 | 5.68 | 960 | 1.81 |

| MR 70 12P | 12,000 | 5 | 324 | 7.00 | 415 | 1.82 |

| HR 40 12M | 12,000 | 6 | 375 | 4.41 | 600 | 1.82 |

| HS 40 12P | 12,000 | 5 | 425 | 4.61 | 430 | 1.85 |

| Fiber type | Filament count |

Filament dia. (µm) |

Tensile modulus (GPa) |

Tensile strength (GPa) |

Yield (mg/m) |

Density (g/cm3) |

|---|---|---|---|---|---|---|

| 34-700 | 12,000 | 7 | 234 | 4.83 | 800 | 1.80 |

| 34-700 | 24,000 | 7 | 234 | 4.83 | 1,600 | 1.80 |

| 37-800 | 30,000 | 6 | 255 | 5.52 | 1,675 | 1.81 |

| 34-600 | 48,000 | 7 | 234 | 4.48 | 3,200 | 1.80 |

| Fiber type | Filament count |

Tensile modulus (GPa) |

Tensile strength (GPa) |

Yield (mg/m) |

Density (g/cm3) |

Thermal conductivity (W/mK) |

Electrical Resistivity (μΩm) |

|---|---|---|---|---|---|---|---|

| K1352U | 2,000 | 620 | 3.60 | 270 | 2.12 | 140 | 6.6 |

| K1392U | 2,000 | 760 | 3.70 | 270 | 2.15 | 210 | 5.0 |

| K13C2U | 2,000 | 900 | 3.80 | 275 | 2.20 | 620 | 1.9 |

| K13C6U | 6,000 | 900 | 3.60 | 760 | 2.18 | 580 | 2.0 |

| K13D2U | 2,000 | 935 | 3.70 | 365 | 2.20 | 800 | 1.5 |

| K13312 | 12,000 | 420 | 3.20 | 1,550 | 2.05 | 110 | 8.0 |

| K63712 | 12,000 | 640 | 2.60 | 2,000 | 2.12 | 140 | 6.6 |

| K63916 | 16,000 | 760 | 2.60 | 2,650 | 2.15 | 190 | 5.3 |

| K13916 | 16,000 | 760 | 3.00 | 2,200 | 2.15 | 200 | 5.1 |

| K63A12 | 12,000 | 785 | 2.60 | 1,950 | 2.15 | 220 | 4.7 |

Note: The values in this table are typical and do not imply any kind of guarantee.