High Performance Polymers & Raw Materials

324 products.

Filter by Application

[Close]

38 products.

[Close all]

DURABIO™ is a bio-based polycarbonate resin derived mainly from plant-based isosorbide. Compared with conventional polycarbonate resin (hereafter abbreviated PC resin) made from bisphenol A (hereafter abbreviated BPA), DURABIO™ features high transparency, excellent optical properties, and outstanding scratch resistance. Its puncture impact behaviour are comparable to those for PC resin. DURABIO™ is a plant-derived polymer but is not biodegradable. It has excellent durability, making possible its deployment in a wide variety of applications such as for optical ・energy related components, a substitute for high-performance glass components, as well as for electronic equipment ・ automotive housings ・ interior and exterior decor.

Maleic anhydride is produced by oxidation of benzene or a C4 hydrocarbon such as butane in the presence of a vanadium oxide catalyst. Maleic anhydride can be converted to maleic acid by hydrolysis and to esters by alcoholysis.

- EINECS: No. 203-571-6

- Japan, Chemical Substances Control Law: METI-No. 2-1101

- Japan, Industrial Safety and Health Law: Dangerous Goods and Toxic Substances Whose Names Should be Labeled and be Notified Appended Table 2-1978

- Japan, Poisonous and Deleterious Substances Control Law: Not applicable.

- Japan, Fire Services Law: Not applicable.

THF (Tetrahydrofuran) is a stable compound with relatively low boiling point and excellent solvency. It is widely-used for dissolution and reaction of various substances. Also it is used as a starting material for the synthesis of poly(tetramethylene ether) glycol (PTMG), etc. Since 1982, Mitsubishi Chemical's Tokai plant has produced high-purity, high-quality THF from butadiene using our proprietary technology.

- EINECS: No. 203-726-8

- Japan, Chemical Substances Control Law: METI-No. 5-53

- Japan, Industrial Safety and Health Law: No. 5-53

- Japan, Industrial Safety and Health Law: Dangerous Goods and Toxic Substances Whose Names Should be Labeled and be Notified Appended Table 2-1278

- Japan, Poisonous and Deleterious Substances Control Law: Not applicable.

- Japan, Fire Services Law: Hazardous Material Class 4 Petroleums No.1 (water-soluble liquid). Hazardous Rank II

- U.N. Class: 3

- U.N. No.: UN2056

NMP (N-Methyl-2-Pyrrolidone) is a polar solvent with outstanding characteristics. It has a wide range of applications because it offers very high solvency, high boiling point, low freezing point, and ease of handling.

- EINECS: No. 212-828-1

- Japan Chemical Substances Control Law: METI-No. 5-113

- Japan, Industrial Safety and Health Law: No. 8-1-1014

- Japan, Industrial Safety and Health Law: Dangerous Goods and Toxic Substances Whose Names Should be Labeled and be Notified Appended Table 2-2108

- Japan, Poisonous and Deleterious Substances Control Law: Not applicable.

- Japan, Fire Services Law: Hazardous material Class 4 Petroleums No.3 (water-soluble liquid).

GBL has a wide range of practical applications because of its low freezing point, high boiling point, and a unique combination of solvent and electrical properties. It has applications as a solvent for special resins, in photography, in batteries, and as an electrolyte. Also a number of derivatives are synthesized from GBL.

- EINECS: No. 202-509-5

- Japan Chemical Substances Control Law: METI-No. 5-3337

- Japan, Industrial Safety and Health Law: No. 5-3337

- Japan, Industrial Safety and Health Law: Dangerous Goods and Toxic Substances Whose Names Should be Labeled and be Notified Appended Table 2-412

- Japan, Poisonous and Deleterious Substances Control Law: Not applicable.

- Japan, Fire Services Law: Hazardous material Class 4 Petroleums No.3 (water-soluble liquid).Aprotic, polar solvent.

FORZEAS™ is a compounding resin developed by Mitsubishi Chemical Corporation using biodegradable and bio-based BioPBS™ and other materials. Each grade has its own unique features and can be used in various applications.

FORZEAS™ can be flexibly formulated depending on customers’ requirements for performance and bio-degradable/bio-based certification.

Biodegradable Polymer, BioPBS™

[Close]

Polybutylene succinate (PBS) is the biodegradable plastic that decomposes into water and carbon dioxide with the microorganism under the soil. PBS has a high heat resistance among the general biodegradablility resin, and PBS has high compatibility with a fiber. Using these goodness, it's possible to achieve the performance which can't be shown by itself as the compound with other resin and material.duct life cycle.

- From Current Needs into the Future

-

Nichigo-POLYESTER recreates the fields of high-tech adhesives, coating binders, and resin modification.

Nichigo-POLYESTER displays excellent adhesive performance with plastic films and moldings including PET, polycarbonate, and vinyl chloride, and metals including aluminum and copper. Used in tandem with isocyanate, melamine, and epoxy resins and other hardening agents, they offer increased heat resistance, solvent resistance, and hardness. Mitsubishi Chemical offers the optimum line-up for all customer needs, including amorphous solvent-soluble, crystalline hot melt, water-soluble, and special types.

Tefabloc™ CP is based on amorphous polyolefins, which not only have high transparency, but also have unique properties not found in other cyclic olefins (COP/COC).

We are developing products for optical applications such as solar panel cover materials utilizing its transparency, and for high-speed communication applications such as 5G and 6G utilizing its low dielectric properties, and can also design products according to customer requirements.

※For medical application, we introduce Zelas™ CP .

A unique tie-layer resin offering excellent adhesive performance to a variety of materials, covering various applications and requirements for automotive, food/non-food packaging, industry and building/construction.

MODIC™ offers two technologies designed to be used as a tie-resin or for peelable purposes:

Soaresin™

[Close]

Soaresin™ is used as a stabilizer or purging agent for extrusion.

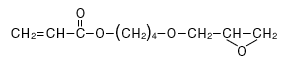

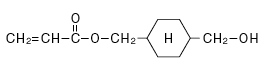

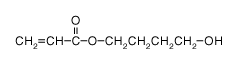

4-HYDROXYBUTYL ACRYLATE, 4HBA

[Close]

- Product Finder

-