Plant

324 products.

Filter by business area

[Close]

74 products.

[Close all]

High Purity Ethylene Carbonate

[Close]

High Purity Ethylene Carbonate. As ethylene carbonate is a highly polar solvent and dissolves large amount of electrolyte, it is mainly used in lithium batteries electrolyte solution. It can also readily dissolve polymers leading to use as a release agent and detergent. Our product is high quality with low impurity levels and low moisture. It has earned an excellent reputation for adherence to the strict quality standards demanded by our customers.

EINECS: No.202-510-0

Japan, Chemical Substances Control Law: METI-No. 5-523

Ethylene Carbonate

[Close]

As ethylene carbonate is a highly polar solvent and dissolves large amount of electrolyte, it is mainly used in lithium batteries electrolyte solution. It can also readily dissolve polymers leading to use as a release agent and detergent. Our product is high quality with low impurity levels and low moisture. It has earned an excellent reputation for adherence to the strict quality standards demanded by our customers.

EINECS: No.202-510-0

Japan, Chemical Substances Control Law: METI-No. 5-523

BioPTMG is a polyether polyol manufactured from plant-derived raw materials.

BioPTMG has the same performance as petroleum-derived PTMG as a raw material for polyurethane and polyester resins and has excellent impact, wear and hydrolysis resistance, flexibility at low temperatures, etc. Taking advantage of these characteristics, it can be used in a wide range of fields, from interior and fashion to industrial materials.

- Grades:

- BioPTMG650、BioPTMG1000、BioPTMG2000、BioPTMG3000

- Japan, Chemical Substances Control Law:

- (7)-129

- Japan, Poisonous and Deleterious Substances Control Law:

- Not applicable.

- Japan, Fire Services Law:

- Hazardous Material Class 4 Petroleums No.4 Hazardous Rank III(BioPTMG650)

Combustible Materials, Flammable Solids(BioPTMG1000, 2000, 3000)

PTMG (Poly(tetramethylene ether)glycol / PTMG) is a linear polyether glycol with hydroxyl groups on both ends. As a polyol, it reacts readily with isocyanates (for example MDI, TDI), etc. to make resins with excellent properties.

- Grades:

- PTMG250、PTMG650、PTMG850、PTMG1000、PTMG1300、PTMG1500、PTMG1800、PTMG2000、PTMG3000、PTMG3200(developed grade in mass production)

- Japan, Chemical Substances Control Law:

- METI-No. 7-129

- Japan, Poisonous and Deleterious Substances Control Law:

- Not applicable.

- Japan, Fire Services Law:

- Hazardous Material Class 4 Petroleums No.3 Hazardous Rank III (PTMG250)

Hazardous Material Class 4 Petroleums No.4 Hazardous Rank III (PTMG650,850)

Combustible Materials, Flammable Solids (PTMG1000, 1300, 1500, 1800, 2000, 3000, 3200(developed grade in mass production))

Maleic anhydride is produced by oxidation of benzene or a C4 hydrocarbon such as butane in the presence of a vanadium oxide catalyst. Maleic anhydride can be converted to maleic acid by hydrolysis and to esters by alcoholysis.

- EINECS: No. 203-571-6

- Japan, Chemical Substances Control Law: METI-No. 2-1101

- Japan, Industrial Safety and Health Law: Dangerous Goods and Toxic Substances Whose Names Should be Labeled and be Notified Appended Table 2-1978

- Japan, Poisonous and Deleterious Substances Control Law: Not applicable.

- Japan, Fire Services Law: Not applicable.

THF (Tetrahydrofuran) is a stable compound with relatively low boiling point and excellent solvency. It is widely-used for dissolution and reaction of various substances. Also it is used as a starting material for the synthesis of poly(tetramethylene ether) glycol (PTMG), etc. Since 1982, Mitsubishi Chemical's Tokai plant has produced high-purity, high-quality THF from butadiene using our proprietary technology.

- EINECS: No. 203-726-8

- Japan, Chemical Substances Control Law: METI-No. 5-53

- Japan, Industrial Safety and Health Law: No. 5-53

- Japan, Industrial Safety and Health Law: Dangerous Goods and Toxic Substances Whose Names Should be Labeled and be Notified Appended Table 2-1278

- Japan, Poisonous and Deleterious Substances Control Law: Not applicable.

- Japan, Fire Services Law: Hazardous Material Class 4 Petroleums No.1 (water-soluble liquid). Hazardous Rank II

- U.N. Class: 3

- U.N. No.: UN2056

NMP (N-Methyl-2-Pyrrolidone) is a polar solvent with outstanding characteristics. It has a wide range of applications because it offers very high solvency, high boiling point, low freezing point, and ease of handling.

- EINECS: No. 212-828-1

- Japan Chemical Substances Control Law: METI-No. 5-113

- Japan, Industrial Safety and Health Law: No. 8-1-1014

- Japan, Industrial Safety and Health Law: Dangerous Goods and Toxic Substances Whose Names Should be Labeled and be Notified Appended Table 2-2108

- Japan, Poisonous and Deleterious Substances Control Law: Not applicable.

- Japan, Fire Services Law: Hazardous material Class 4 Petroleums No.3 (water-soluble liquid).

GBL has a wide range of practical applications because of its low freezing point, high boiling point, and a unique combination of solvent and electrical properties. It has applications as a solvent for special resins, in photography, in batteries, and as an electrolyte. Also a number of derivatives are synthesized from GBL.

- EINECS: No. 202-509-5

- Japan Chemical Substances Control Law: METI-No. 5-3337

- Japan, Industrial Safety and Health Law: No. 5-3337

- Japan, Industrial Safety and Health Law: Dangerous Goods and Toxic Substances Whose Names Should be Labeled and be Notified Appended Table 2-412

- Japan, Poisonous and Deleterious Substances Control Law: Not applicable.

- Japan, Fire Services Law: Hazardous material Class 4 Petroleums No.3 (water-soluble liquid).Aprotic, polar solvent.

12BG (1,2-butanediol) is a branched glycol that has a primary hydroxyl group and a secondary hydroxyl group on adjacent carbon atoms. Mitsubishi Chemical Corporation offers two grades of purity. Both can be reacted with a dicarboxylic acid (e.g., phthalic acid or adipic acid) for use as a polyester polyol or a plasticizer, or reacted with an unsaturated dicarboxylic acid (e.g., maleic anhydride) for use as a raw material for unsaturated polyester resin. The high-purity grade 12BG is suitable for use as a solvent for inks and as a raw material for surfactants.

- EINECS: No. 209-527-2

- Chemical Substance Control Law (CSCL): METI-No. 2-235

- Japan, Industrial Safety and Health Act (ISHA): No. 2-235

- Japan, Poisonous and Deleterious Substances Control Act: Not applicable.

- Japan, Fire Service Act:Hazardous Materials, Category IV—Class III petroleums (water soluble liquids)

14BG (1,4-Butanediol) is a straight chain glycol with hydroxyl groups on both ends. It is used as a raw material for high performance polyester and polyurethane resins as well as for industrial chemicals like tetrahydrofuran and gamma-butyrolactone. Since 1982, Mitsubishi Chemical's Tokai plant has produced high-purity, high-quality 14BG from butadiene using our proprietary technology.

- EINECS: No. 203-786-5

- Japan, Chemical Substances Control Law: METI-No. 2-235

- Japan, Industrial Safety and Health Law: No. 2-235

- Japan, Poisonous and Deleterious Substances Control Law: Not applicable.

- Japan, Fire Services Law: Hazardous material Class 4 Petroleums No.3 (water-soluble liquid).

Polycarbonatediol, BENEBiOL™

[Close]

Polycarbonatediol(PCD) is a linear polycarbonate with hydroxyl groups at both ends. It easily reacts with isocyanate compounds(e.g. MDI, TDI, IPDI, H12MDI), and generates polymers with characteristics such as durability and chemical/hydrolysis resistance. BENEBiOL™ is the biomass-based PCD developed by our proprietary manufacturing technology. Because of “key monomer“ of each grade, polyurethane resins based on BENEBiOL™ will show an outstanding property level with regard to flexibility and chemical/stain resistance for example, in addition to the characteristics of conventional PCD. Besides, your product will be equipped with unique touch and feeling.Biomass-based polycarbonatediol with superior characteristics

Characteristics of polyurethane resins based on BENEBiOL™

non-edible raw material is used for some grades

transparency, stain resistance, chemical resistance, durability, toughness, weather resistance

flexibility, soft feel and touch, high hardness, good fit

DIAPOL™-WMB is a composite material (wet masterbatch) produced by acid coagulation of SBR latex, carbon black and water slurry in an ultradispersion process. It is widely applied as a raw material for industrial products; water seals and gaskets; and tires and belts.

MITSUBISHI™ Carbon Black is a black pigment that has been used in a wide range of fields such as newspaper ink, printing ink, colored resin, paint, toner, colored paper, India ink, and ceramics.

Various grades of carbon blacks are available ranging from all- purpose grade to high-grade. In addition, our line of products includes industrial and environmentally-friendly carbon blacks.

- Carbon Black Association Handbook 3rd edition (Ref. 1)

- Carbon Black Association Annual Report No.75(2025)(Ref. 2)

- Acrylic Pressure Sensitive Adhesives (PSA)

―To Create New Value for Your Needs -

COPONYL is pressure sensitive adhesive(PSA) resin made mainly from acrylic acid ester using such solvents as ethyl acetate and toluene. The demand for PSA is increasing and expanding: they are now used in a wide range of applications including labels, single/double-sided tapes, foams, and electronic applications such as protective masking films.

Roller (CARBOLEADER ™)

[Close]

CARBOLEADER™ is a carbon roller that simultaneously offers light weight, high rigidity, and a high critical number of revolutions. It is used for a wide range of applications, including separators for rechargeable batteries, for optical applications and all kinds of films, for printing, and paper manufacture. It can significantly increase productivity and reduce costs by improving production quality and speed, and reducing defect rates.

C/C composite, C/SiC composite

[Close]

C/C (carbon fiber reinforced carbon) composites are made of carbon matrix reinforced with carbon fiber, and have high strength, high elasticity, high toughness, and ultra-high heat resistance, and can be used at temperatures above 1,000ºC.

C/SiC, also known as ceramic matrix composite (CMC), is a composite material with a ceramic matrix, and our CMC is reinforced with carbon fiber. It has higher strength and elasticity than C/C composite, and can be used in a wider variety of applications.

Carbon fiber composite materials, also known as carbon fiber reinforced plastics (CFRP), are composite materials made of carbon fibers and resin (mainly epoxy resin).

As light, strong, and hard materials, they are used in wide range of applications such as sporting goods, industrial, aircraft and automobile components. By selecting suitable resin, it is possible to add features like heat resistance, impact resistance, and flame retardant, and thus provide superior characteristics not found in conventional metals and ceramics to enable a reduction in the weight of parts, give freer design.

Compared with conventional steel plate or concrete-jacketed reinforcements, REPLARK simplifies construction and shortens construction period by eliminating the need for heavy machinery. For its high strength, lightweight, high durability, and excellent workability, REPLARK has earned an outstanding reputation for the repair and reinforcement of bridge piers, floorboards, columns, chimneys, and for other structural applications.

e-Plate/Leadline: This repair and reinforcement material enables reinforcement by simply attaching or embedding prefabricated carbon fiber reinforced plastics (CFRP), without the need for resin impregnation or for layering the required amount of reinforcement, as in the case of repair and reinforcement using carbon fiber sheets, thereby reducing construction time and improving construction quality.

ZEBREX™ is cutting-edge zeolite membrane dehydration process, which can dehydrate solvents under a wide range of water concentration and pH conditions, and is a one-pass continuous process rather than a batch process.

ex.) Ethanol, Isopropanol, Acetone, Methyl Ethyl Ketone, Tetrahydrofuran, etc.

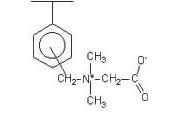

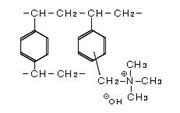

DIAION™ AMP03 is an amphoteric ion-exchange resin with a quaternary ammonium group and carboxy group incorporated into the crosslinked polystyrene backbone. Thanks to uniform 260 µm beads size, AMP03 realizes sharp elution peak in the separation of electrolytes from non-electrolytes, between electrolytes (sodium chloride and sodium sulfate), etc.

A chelating resin has a functional group that is capable of forming a chelate (complex) with a metal ion. The specific metals that can form chelates with the functional group can be captured. In the DIAION™ CR Series, there are three product types: (1) for common metals -- DIAION™ CR11 with the iminodiacetic acid functional group, (2) for metals other than alkali metals (Na, K, etc.) or alkaline earth metals (Ca, Mg, etc.) -- DIAION™ CR20 with the polyamine group, and (3) for selectively capturing boric acid --- CRB03 and CRB05 with the methylglucamide group.

The low-odor, low-leachable anion exchange resin reduces the release of total organic carbon (TOC) and amines to prevent offensive odors.

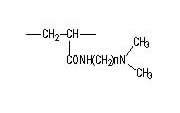

The weakly basic anion exchange resins use either a polystyrene or polyacrylic ester frame and a primary-ternary amino group as the functional group. Although the anion of a salt like NaCl or Na2SO4 cannot be exchanged, the exchange of an anion of a mineral acid such as HCl and H2SO4, or the salt of a weak base like NH44Cl can be carried out.

An amino functional group is incorporated into the anion exchange resin enabling the exchange of anions like the Cl- ion and the SO4-- ion. Strongly basic anion exchange resins and weakly basic anion exchange resins can be defined according to the basic strength of the amino functional group.

The ion exchange resin that has a quaternary ammonium group is strongly alkaline and dissociates just like NaOH and KOH. Therefore it is called a strongly basic anion exchange resin.

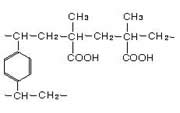

The weakly acidic cation exchange resins have the carboxylic acid group (-COOH) as the exchange group. There are two kinds --- a methacrylic acid type and an acrylic acid type. The acrylic acid weakly acidic cation exchange resin is used for processing water with high carbonate hardness. The methacrylic acid type is used for purification of antibiotics and amino acids.

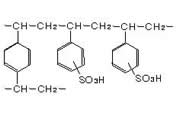

The strongly acidic cation exchange resins are bead-like products which have a sulfonic acid group in the cross-linked styrene frame. They can be used across the full pH range (0-14), and are relatively stable to temperature, even withstanding high temperatures of 100-120℃. They are used in a wide variety of fields including water purification, water softening, wastewater treatment, purification of pharmaceuticals and food, and catalysis.

Soarlite is the trade name of ethylene-vinyl alcohol copolymer for injection molding application as engineering plastics.

Soaresin™

[Close]

Soaresin™ is used as a stabilizer or purging agent for extrusion.

Synthetic Paper , YUPO™

[Close]

"YUPO" is a synthetic paper made from polypropylene resin as its primary material. It offers extraordinary beauty, strength and flexibility. YUPO combines the advantages of both paper and plastic film, and thanks to its unique qualities, it is used widely in several fields, including the commercial printing, packaging and communication paper.

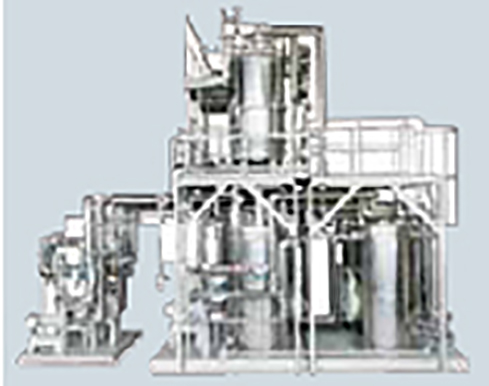

Separation & Purification System

[Close]

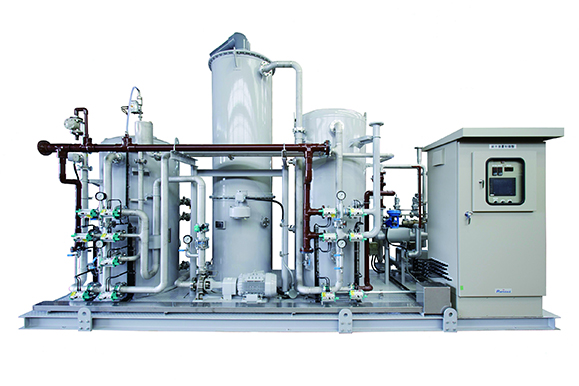

Water Treatment System

[Close]

Plastic Filtering Plate

[Close]

Made form high quality polypropylene (PP), our wide range of filtering materials for filter press machines include lightweight filter plates with excellent chemical resistance and high impact strength, plastic membranes with superb thermal and chemical resistance, and filter-press-plate unit combined with anticorrosive plastic membrane.

- Product Finder

-