- Mitsubishi Chemical Corporation

- Engineering Shapes & Solutions Div.

Injection Molded Products

Mitsubishi Chemical CorporationThe High-performance Molding Systems Division has injection molding production bases in Nagahama City in Shiga Prefecture and Ogaki City in Gifu Prefecture. We provide various high-quality products primarily in the automotive industry via a consistent production process from die manufacturing to product delivery so as to meet our customers' needs. Our in-house production system incorporates many different coating technologies in addition to our injection molding technologies.

Production Technologies

[Close]

Injection-molding technology

We use the latest technologies to manufacture small and large products to customers' exact specifications.

Some of our more robust technologies include heat/cool molding technologies to create highly attractive products, in-molding, film insert molding, gas-assisted molding, injection-compression molding, and two-color molding processes.

Painting technology

Efficient operation of painting robots, providing high gloss, multicolor paints and UV coatings. We also use a hard-coat to apply a UV coating to transparent parts.

Print and assembly

To meet ever more advanced and complex market needs, we also focus on assembly and processing. We can handle a wide variety of requirements from external finishes using pad printing and silk printing to heater/ultrasonic welding, assembly of various parts, unit implementation and finished products.

Product Lineup

[Close]

- Automotive parts and components (e.g. interior parts, automotive components)

- Audio Visual-related products

- IT-related products

- Home appliance products

- Game machine parts and components

- Robot parts

Example Applications

[Close]

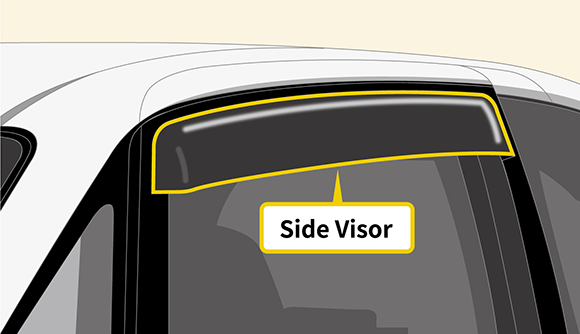

Transparent automotive parts

We use heat/cool molding and injection-compression molding technologies to create highly attractive products with minimal strain. We use hard-coating technologies to harden the surface of these products. We also use film insert molding technologies to provide new and extending functionality such as low reflectivity and surface hardening. These technologies and processes enable us to provide highly functional, transparent automotive parts.

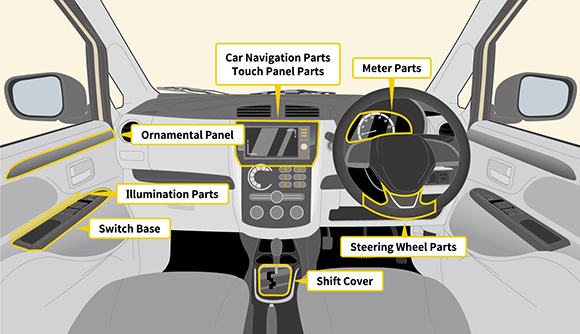

Automotive interior parts

We use high-gloss coatings and multicolor coating technologies to create highly attractive parts while also using heat/cool molding technologies to create highly attractive products without any coatings.

Group Companies

[Close]

MCC Advanced Moldings Co., Ltd.

We develop many different products in accordance with customer needs. The major types of products we provide include precision electronic parts using carbon nanotubes, molded parts for dental and medical inspection equipment, functional films including color printer intermediate transfer belts, and optical parts such as LED modules.

MCC Advanced Moldings Co., Ltd. Website[Open in a new window]

Inquiries Concerning Products

View the products of Engineering Shapes & Solutions Div., Mitsubishi Chemical[Open in a new window]