Information / Electronics / Display / Battery

324 products.

Filter by Application

[Close]

72 products.

[Close all]

High Purity Ethylene Carbonate

[Close]

High Purity Ethylene Carbonate. As ethylene carbonate is a highly polar solvent and dissolves large amount of electrolyte, it is mainly used in lithium batteries electrolyte solution. It can also readily dissolve polymers leading to use as a release agent and detergent. Our product is high quality with low impurity levels and low moisture. It has earned an excellent reputation for adherence to the strict quality standards demanded by our customers.

EINECS: No.202-510-0

Japan, Chemical Substances Control Law: METI-No. 5-523

Ethylene Carbonate

[Close]

As ethylene carbonate is a highly polar solvent and dissolves large amount of electrolyte, it is mainly used in lithium batteries electrolyte solution. It can also readily dissolve polymers leading to use as a release agent and detergent. Our product is high quality with low impurity levels and low moisture. It has earned an excellent reputation for adherence to the strict quality standards demanded by our customers.

EINECS: No.202-510-0

Japan, Chemical Substances Control Law: METI-No. 5-523

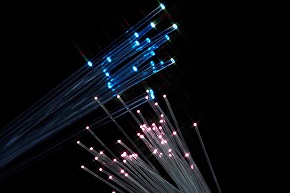

Plastic Optical Fiber, Eska™

[Close]

ESKA is a plastic optical fiber product that exploits the excellent light-transmission properties of acrylic resins. It possesses a number of important characteristics not found in glass optical fiber, including light weight, flexibility, and easy processability. We are marketing ESKA for a wide number of applications in the fields of automotive networks, lighting, sensors, FA (Factory Automation) and data transmission.

Rod Lens Arrays, Rodscope™

[Close]

- Acrylic Pressure Sensitive Adhesives (PSA)

―To Create New Value for Your Needs -

COPONYL is pressure sensitive adhesive(PSA) resin made mainly from acrylic acid ester using such solvents as ethyl acetate and toluene. The demand for PSA is increasing and expanding: they are now used in a wide range of applications including labels, single/double-sided tapes, foams, and electronic applications such as protective masking films.

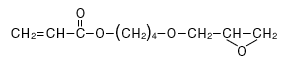

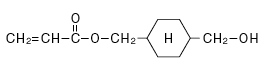

- SHIKOH ――UV Curable Resin from Mitsubishi Chemical

-

UV curable resin is garnering wide spread attention for its low-polluting, energy-saving properties and high productivity.

Mitsubishi Chemical offers a wide lineup of such resin under the SHIKOH brand name, with a special emphasis on urethane acrylate oligomer.

In addition to hard coating application, SHIKOH is suitable for use in a wide range of applications. Mitsubishi Chemical's SHIKOH holds the key to the future of ultraviolet curable resin.

- From Current Needs into the Future

-

Nichigo-POLYESTER recreates the fields of high-tech adhesives, coating binders, and resin modification.

Nichigo-POLYESTER displays excellent adhesive performance with plastic films and moldings including PET, polycarbonate, and vinyl chloride, and metals including aluminum and copper. Used in tandem with isocyanate, melamine, and epoxy resins and other hardening agents, they offer increased heat resistance, solvent resistance, and hardness. Mitsubishi Chemical offers the optimum line-up for all customer needs, including amorphous solvent-soluble, crystalline hot melt, water-soluble, and special types.

Developed to respond to the increasing trends toward compactness and high speed of printers, this product has attracted considerable attention. We intend to develop into the field of color toners to expand the potential market further.

Tomirac KN is a high heat-resistant developer for thermal paper.

Injection Molded Products

[Close]

The High-performance Molding Systems Division has injection molding production bases in Nagahama City in Shiga Prefecture and Ogaki City in Gifu Prefecture. We provide various high-quality products primarily in the automotive industry via a consistent production process from die manufacturing to product delivery so as to meet our customers' needs. Our in-house production system incorporates many different coating technologies in addition to our injection molding technologies.

High thermal conductive BN sheet

[Close]

Proprietary BN fillers which have features of high thermal conductivity and isolation are packed into the resin sheet at high density. High-purity epoxy resin is developed and used as binder. It is suitable for power modules used in inverters, and achieves both thermal resistance and isolation equivalent to those of ceramic plate (in-house measurement result).

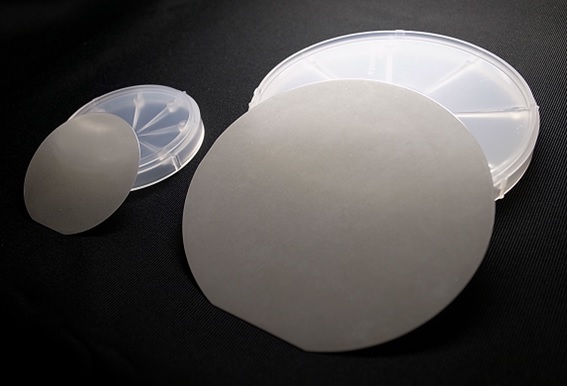

GaN Wafer (GaN substrate)

[Close]

Mitsubishi Chemical's Gallium Nitride (GaN) substrate is a high-quality single-crystal substrate. It is made with original HVPE method and wafer processing technology, which has been originally developed for many years. The features are high crystalline, good uniformity, and superior surface quality. GaN substrates are used for LD applications (violet, blue and green).

Furthermore, development has progressed for power and high frequency electronic device applications. In order to achieve lower defect and higher productivity, we have been developing the GaN substrates manufactured by SCAAT™(*) and SCAAT™-LP(**).

- *SCAAT™ is the brand name of an acidic ammonothermal technology implemented by Mitsubishi Chemical Corporation. This technology was established through the cooperation of Tohoku University, The Japan Steel Works, Ltd., and Mitsubishi Chemical Corporation.

- **SCAAT™-LP is the brand name of a low pressure acidic ammonothermal technology implemented by Mitsubishi Chemical Corporation and The Japan Steel Works, Ltd. This technology was jointly developed by Tohoku University, The Japan Steel Works, Ltd., and Mitsubishi Chemical Corporation.

NEWS LETTER -Gallium nitride (GaN), a material to support future society-([PDF]465KB)

This photosensitive polymer for photo resists is used during the formation of semiconductor circuits.

This material is designed to satisfy strict quality requirements, such as high purity and low metal content, associated with the miniaturization of circuit patterns.

Our services include polymer design, prototyping, and mass production.

This antistatic agent is used to prevent electrons from accumulating on the resist surface during electron beam lithography.

This material is used in advanced photomask manufacturing to help prevent charge-up failures.

Antistatic Agent, aquaPASS™

[Close]

This water-based antistatic agent is derived from polyaniline-based, water-soluble electroconductive polymers.

This agent prevents particles from adhering due to static electricity when used as a coating on films and plastic substrates.

Use of this agent enables the production of thin films with excellent antistatic performance, transparency, and minimal humidity dependency.

During the post CMP cleaning process in semiconductor manufacturing, it is important to remove organic residues and particles on Cu wires and Low-k films without damaging the substrate. Our product, MCX-SDR4, is a high-efficiency cleaning solution suited for semiconductor industries.

Characteristics:

- High efficiency particle removal

- Removes organic residues effectively

- Limits galvanic corrosion on Cu wire

- Limits Low-k damage

- Improves Low-k wetting properties

In recent years, the demand is increasing for high quality removal of metals from small size semiconductor circuits during silicon wafer cleaning process. Star Series meets this demand with semiconductor process chemicals having metal impurity levels below 10ppt.

Products: Hydrochloric acid

MC1 is an electronic chemical processing solution which is a high-performance alternative RCA clean. MC1 contributes to the customer`s total cost reduction, because it can remove both particles and metals, thus reducing the number of steps of RCA cleaning. Features: ・Reduction of metal contamination ・Prevention of cross contamination

X-ray Scintillator Screen, DRZ™

[Close]

Scintillator is a material that convert radial ray such as X-ray into the visible light. By using with a light detector such as TFT, CCD, CMOS sensors, The image can be efficiently converted to a digital image.

Mitsubishi Chemical has its own phosphor manufacturing technology and processing know-how, including the DRZ series used for medical X-ray diagnostic imaging and baggage inspection, We have commercialized excellent scintillators for digital X-ray equipment such as Short Decay and Low Afterglow Type used for high-speed line sensors for contamination inspection.

Phosphors for optical devices

[Close]

Phosphor is a material which absorbs light energy, such as ultraviolet and visible rays, and converts it into certain light. Mitsubishi Chemical Corporation has long experience in development and manufacture of phosphor for more than 50 years. Based on manufacturing technology derived from this experience, Mitsubishi Chemical Corporation provides phosphors for optical devices such as LED and lasers.

OPC Drum

[Close]

Toner

[Close]

OPLFILM™ is the trade name of PVOH(PVA) (polyvinyl alcohol) film for use in polarizing film for liquid crystal displays (LCD). We provide wide-ranging technical expertise and optimum materials that maximize our polarizing film manufacturing experience.

A high‑performance composite that bonds metal and plastic film under extreme pressure—no adhesives required.

Key Features

- Pure Mechanical Lamination

Metals and polymer films are fused through a proprietary process, delivering exceptional peel strength and durability without resin or adhesive layers. - Custom Combinations

Choose your ideal metal + film pairing, thickness and finish to match your exact specifications. - Broad Compatibility

- Metals:

- Aluminum、Stainless steel (SUS)、Electro galvanized steel (SECC)、Zn-Al-Mg alloy (ZAM)

[under development]Copper - Resin Films:

- Polyamide (PA)、Polypropylene (PP)、Ultra high molecular weight polyethylene (UHMWPE)、Fluoropolymers、PET (polyethylene terephthalate)

[under development]PC 、PBT 、PPS、PEI

Specifications & Custom Orders

- Width: up to 500 mm max.

(Actual maximum depends on metal type and thickness—please inquire for details.) - Thickness & Layering: fully customizable—mix and match metal and film layers as needed.

- Special Requests: if you don’t see your preferred metal or film listed, please contact us—many additional materials can be accommodated.

At Mitsubishi Chemical, we offer the high-performance engineering plastic film "SUPERIO™ UT". Leveraging our many years of accumulated technology and experience, we are currently mass-producing films made from PEI (polyetherimide) and PEEK (polyether ether ketone). These films have been adopted across a wide range of industries and applications, including automotive, electronics, and aerospace. To meet the increasingly diverse needs of our customers, we are actively engaged in the development and commercialization of an even broader range of high heat-resistant films. We also offer customized solutions tailored to specific customer requirements. If you are interested in high-performance engineering plastic films, please feel free to contact us.

Electronic Functional Materials

[Close]

Silicone rubber film, KEIJU™

[Close]

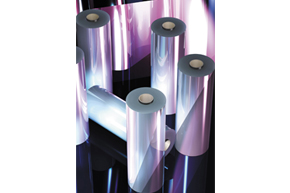

With a comprehensive lineup of polyester film, ranging from a few microns to 350 microns in thickness and featuring well-balanced characteristics such as mechanical properties and heat resistance. Customers across the globe in further increasing applications have been using DIAFOIL.

We integrate three technologies of Mitsubishi Chemicals, namely, excellent and proprietary material technologies, film-forming technology cultivated over many years and surface treatment technology with unique coating, and develop new markets with customers to become a leading global company.

Working closely with the polymer and engineering operations, our polyester film operations take advantage of the latest information and technology to make quality improvement and process enhancement. This allows us to meet a wide range of our customers' needs. In this way, we continue to strive to offer satisfaction to customers and build long-lasting, strong relationships. We are continuing to make efforts, devoting ourselves to R&D activities to provide even more sophisticated products.

- Product Finder

-