Industrial・Medical Films Dept. / Mosmite

11products.

[Close all]

Moth Eye-type Antireflective Film, MOSMITE™

[Close all]

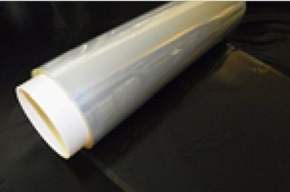

Acrylic Film, ACRYPLEN™

[Close all]

We have been engaged since 1975 in the development, manufacture, and sale of acrylic (PMMA) films through a combination of our unique in-house polymer design and thin film forming technologies.

ACRYPLEN (acrylic film) features the excellent transparency, weatherability, suitability for heat-molding and lamination processing. In addition, it has outstanding UV protection, making it ideal for use as a construction material, a paint-alternative, and a retro reflective material, as well as for a wide range of applications in the field of optical engineering.

Mitsubishi Chemical is a pioneer in the development of acrylic films, and the Company’s lineup encompasses products with a wide variety of thicknesses, widths, and differing degrees of flexibility/rigidity.

Multilayer Co-extruded Film for Medical Supplies and Pharmaceuticals Packaging, DIAMIRON™

[Close all]

We are able to create co-extruded films by using our unique co-extrusion technology to merge multiple resins together in a die.

This high-performance film inherits the properties of each resin used.

We can customize the properties of the film with functionality based on your needs, such as producing a film with high barrier properties.

We constructed a special, clean production environment to produce DIAMIRON as an extremely high-quality primary container. This material is used in such products as transfusion and infusion bags and sterile blister packs for medical supplies.

DIAMIRON is produced at the Azai Plant under ISO 9001 and FSSC 22000-compliant quality control.

Visit the product website for more information.

Applications

- Sterile blister packs for medical supplies

- Transfusion bags

Moisture Transmission Film

[Close all]

Pharmaceutical Grade Moisture-proof Sheeting

[Close all]

This plastic sheet is used to manufacture press-through packages (PTP) manufactured under Good Manufacturing Practices (GMP) required for medical packaging materials. This material complies with Notification 370 from the Ministry of Labour and Welfare issued in 1959, the Japan Hygienic PVC Association (JHP) standards, and Japan Hygienic Olefin and Styrene Plastics Association PL standards. This material is also registered in the US Food and Drug Administration (FDA) drug master file.

We use various testing equipment such as actual packaging machines used by the pharmaceuticals industry to ensure packaging properties of each material.

We are engaged in development to improve stability of pharmaceuticals manufacturing as well as incorporate the perspective of users including both patients and pharmacists.

Heat-Shrinkable Tube, HISHITUBE™

[Close all]

Sheets for Cards

[Close all]

Metal-Resin Film Laminated Material, ALSET™

[Close all]

A high‑performance composite that bonds metal and plastic film under extreme pressure—no adhesives required.

Key Features

- Pure Mechanical Lamination

Metals and polymer films are fused through a proprietary process, delivering exceptional peel strength and durability without resin or adhesive layers. - Custom Combinations

Choose your ideal metal + film pairing, thickness and finish to match your exact specifications. - Broad Compatibility

- Metals:

- Aluminum、Stainless steel (SUS)、Electro galvanized steel (SECC)、Zn-Al-Mg alloy (ZAM)

[under development]Copper - Resin Films:

- Polyamide (PA)、Polypropylene (PP)、Ultra high molecular weight polyethylene (UHMWPE)、Fluoropolymers、PET (polyethylene terephthalate)

[under development]PC 、PBT 、PPS、PEI

Specifications & Custom Orders

- Width: up to 500 mm max.

(Actual maximum depends on metal type and thickness—please inquire for details.) - Thickness & Layering: fully customizable—mix and match metal and film layers as needed.

- Special Requests: if you don’t see your preferred metal or film listed, please contact us—many additional materials can be accommodated.

Super Engineering Plastic Film, SUPERIO™ UT

[Close all]

At Mitsubishi Chemical, we offer the high-performance engineering plastic film "SUPERIO™ UT". Leveraging our many years of accumulated technology and experience, we are currently mass-producing films made from PEI (polyetherimide) and PEEK (polyether ether ketone). These films have been adopted across a wide range of industries and applications, including automotive, electronics, and aerospace. To meet the increasingly diverse needs of our customers, we are actively engaged in the development and commercialization of an even broader range of high heat-resistant films. We also offer customized solutions tailored to specific customer requirements. If you are interested in high-performance engineering plastic films, please feel free to contact us.

Electronic Functional Materials

[Close all]

Silicone rubber film, KEIJU™

[Close all]

- Product Finder

-