Polycarbonatediol BENEBiOL™

- Mitsubishi Chemical Corporation

C4 & PBT Dept.

- Mitsubishi Chemical Europe GmbH (for EU customer)

These are links for moving within this page

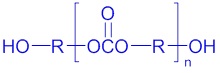

Polycarbonatediol(PCD) is a linear polycarbonate with hydroxyl groups at both ends. It easily reacts with isocyanate compounds(e.g. MDI, TDI, IPDI, H12MDI), and generates polymers with characteristics such as durability and chemical/hydrolysis resistance.

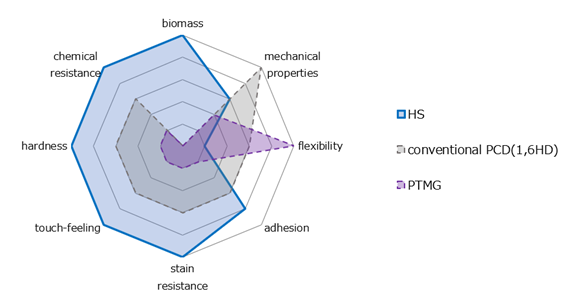

BENEBiOL™ is the biomass-based PCD developed by our proprietary manufacturing technology. Because of “key monomer“ of each grade, polyurethane resins based on BENEBiOL™ will show an outstanding property level with regard to flexibility and chemical/stain resistance for example, in addition to the characteristics of conventional PCD. Besides, your product will be equipped with unique touch and feeling.

Biomass-based Polycarbonatediol BENEBiOL to Be Used in AEROX's Coatings for Wind Turbine Blade Leading Edge Protection[Open in a new window]

Biomass-based Polycarbonatediol “BENEBiOL” Adopted for the Watch Band of Citizen Watch[Open in a new window]

[Close]

| Common Name | Polycarbonatediol |

|---|---|

| Product Name | BENEBiOL™ |

| Structure |  |

| Packing | Drum 180-200㎏ 18-Liter square can 16-18㎏ |

| Applications | Polyurethane applications Acrylic resin applications Polyester applications |

| HS grade | NLDB/DS/D grade | NLS grade | |

|---|---|---|---|

| raw material | biomass-based | biomass-based | biomass-based |

| characteristics | High hardness Toughness Chemical resistance Stain resistance Wheather resistance Bacteria repellency |

Flexibility Chemical resistance Mechanical properties |

Stain resistance Chemical resistance Mechanical properties Unique touch |

HS grade

High hardness

Toughness

Chemical resistance

Stain resistance

Wheather resistance

Bacteria repellency

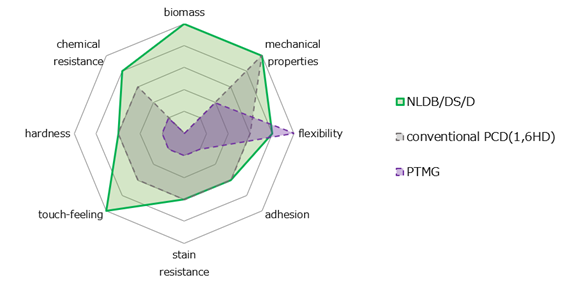

NLDB/DS/D grade

Flexibility

Chemical resistance

Mechanical properties

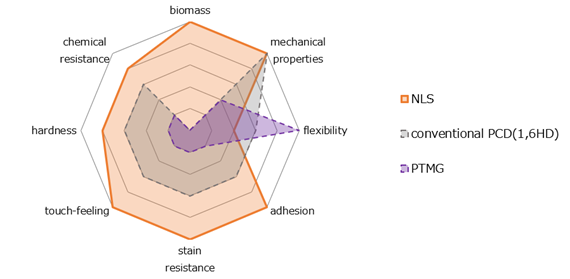

NLS grade

Stain resistance

Chemical resistance

Mechanical properties

Unique touch

[Close]

| HS | NLDB/DS/D | NLS | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| HS0830S | HS0840S | HS0840H | HS0850H | NL1030DS | NL1570DB | NL2010DS | NL2030DS | NL3010DS | NL1000D | NL2000D | NL1030S | NL2005S | NL2030S | |

| Mn Number average molecular weight |

800 | 800 | 800 | 800 | 1000 | 1500 | 2000 | 2000 | 3000 | 1000 | 2000 | 1000 | 2000 | 2000 |

| Bio-based %* |

84 | 84 | 37 | 44 | 86 | 78 | 82 | 85 | 82 | 93 | 92 | 54 | 75 | 54 |

| Appearance (at 25℃) |

Highly-viscous liquid | Highly-viscous liquid | Highly-viscous liquid | Highly-viscous liquid | Viscous liquid | White solid | White solid | Viscous liquid | White solid | White solid | White solid | Viscous liquid | White solid | Highly-viscous liquid |

| Hazen APHA |

<100 | <100 | <100 | <100 | <100 | <100 | <100 | <100 | <100 | <100 | <100 | <100 | <100 | <100 |

| OH Value mgKOH/g |

140±10 | 140±10 | 140±10 | 140±10 | 110±10 | 75±8 | 56±5 | 56±5 | 37±3 | 110±10 | 56±5 | 110±10 | 56±5 | 56±5 |

| Viscosity mPa・s (at 60℃) |

5,000 ~12,000 | 15,000 ~35,000 | 3,000 ~15,000 | 10,000 ~28,000 | 600 ~1,200 | 1000 ~1,800 | 6,000 ~11,000 | 4,000 ~8,000 | 20,000 ~33,000 | 250~600 | 600 ~1,300** | 1,500 ~4,500 | 8,000 ~14,000 | 14,000 ~27,000 |

| Water wt% |

≦0.05 | ≦0.05 | ≦0.05 | ≦0.05 | ≦0.05 | ≦0.05 | ≦0.05 | ≦0.05 | ≦0.05 | ≦0.05 | ≦0.05 | ≦0.05 | ≦0.05 | ≦0.05 |

| Flash point ℃ |

247 | 226 | 257 | 247 | 223 | 254 | 237 | 254 | 265 | 244 | 250 | 248 | 264 | 242 |

| Melting point ℃ |

10~20 | n.d. | n.d. | n.d. | 10~20 | 35~45 | 40~50 | 15~25 | 45~55 | 45~55 | 50~60 | n.d. | 45~55 | n.d. |

| Acid Value mgKOH/g |

≦0.5 | ≦0.5 | ≦0.5 | ≦0.5 | ≦0.5 | ≦0.5 | ≦0.5 | ≦0.5 | ≦0.5 | ≦0.5 | ≦0.5 | ≦0.5 | ≦0.5 | ≦0.5 |

*measured value by ASTM D6866 method

**at 80℃

Note: The values in the table are representative values and are not specifications.

[Close]

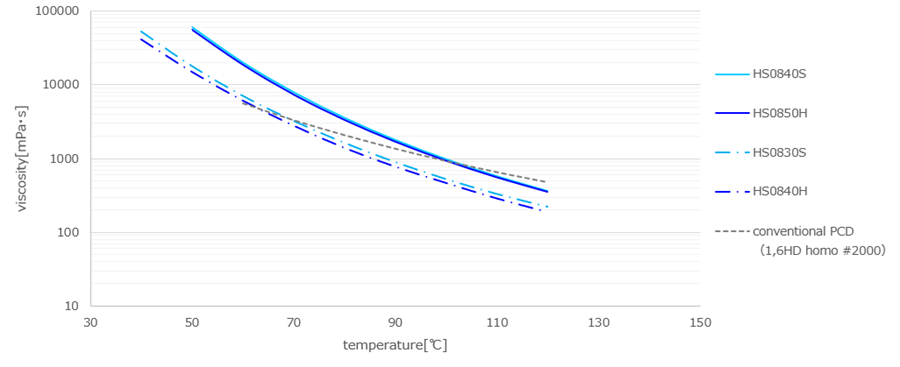

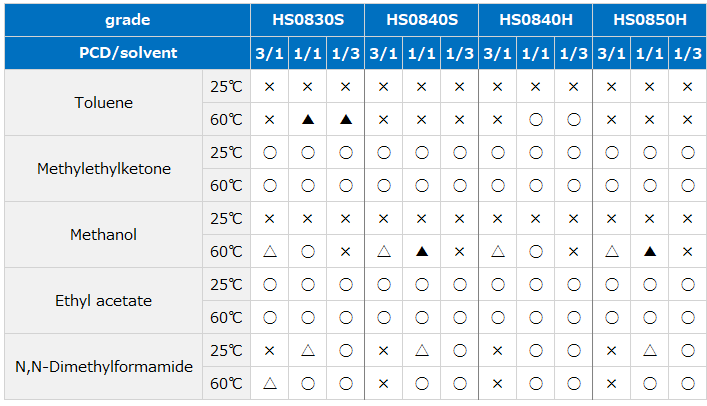

HS

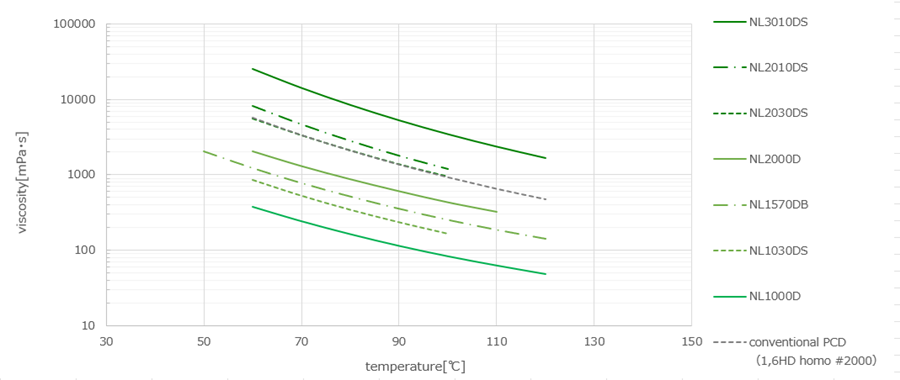

NLDB/DS/D

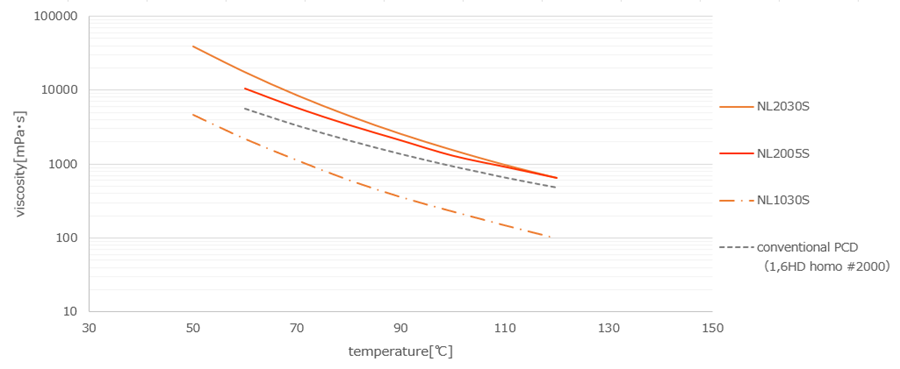

NLS

[Close]

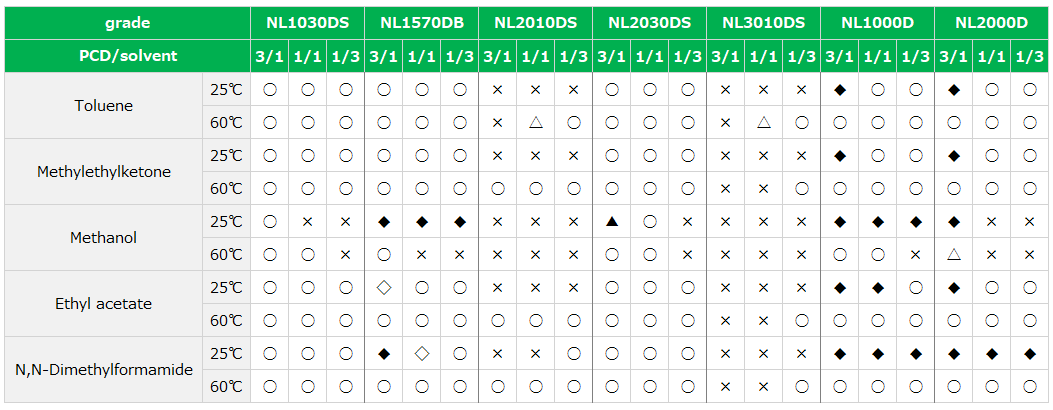

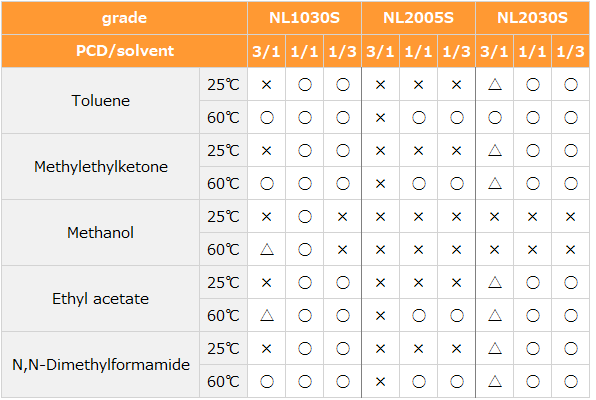

◯:soluble、△:mostly soluble、▲:emersion、×:insoluble、◆:crystallized

[Close]

BENEBiOL™ should be sealed in a container with dry nitrogen since it is moderately hygroscopic.

NLDB/DS/D and NLS(NL2005S) grades are solid at room temperature, and it can become a colorless transparent liquid when heated.

Before using “BENEBiOL™”, it should be heated at temperature above its melting point.

Under transport regulations, “BENEBiOL™” is not classified as UN hazard class.

“BENEBiOL™” has low volatility and will not spontaneously ignite at room temperature.

Safety glasses and protective gloves should be worn when handling “BENEBiOL™”.

For further details, please refer to Safety Data Sheets issued by Mitsubishi Chemical Corporation.

“BENEBiOL™” are produced for industrial applications. If the intended use for “BENEBiOL™” is for body contact applications such as pharmaceuticals, food and cosmetics, please contact Mitsubishi Chemical Corporation in advance.

Polycarbonatediol BENEBiOL™

View the products of C4 & PBT Dept.(BENEBiOL), Mitsubishi Chemical[Open in a new window]

This is the end of this page