Medical Amorphous Polyolefin Zelas™ CP

- Mitsubishi Chemical Corporation

- Performance Polymers Dept.

These are links for moving within this page

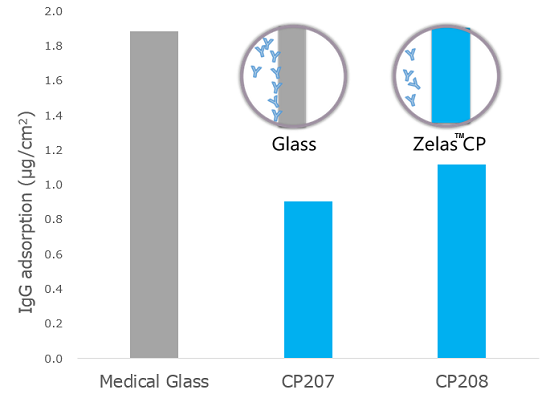

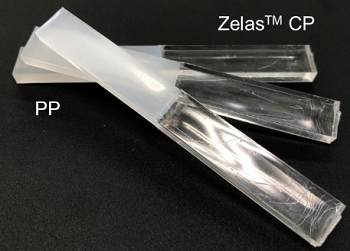

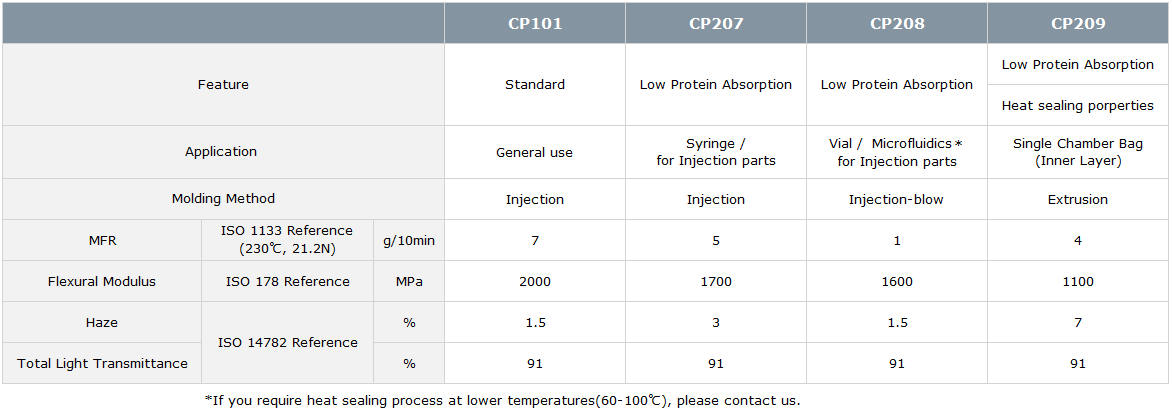

Zelas™ CP is a polymer compound products based on amorphous polyolefin with high transparency, which is designed to be suitable as a material for medical devices such as medical vials and syringes that require low adsorption of pharmaceuticals and high hygiene.

Zelas™CP has excellent heat-sealing and dissimilar-material adhesion properties, and can be applied as an inner layer of two-color molding or backing, contributing to improved design of medical device components.

※For industrial applications and when good adhesion to metal is required, we introduce Tefabloc™ CP .

[Close]

[Close]

[Close]

[Close]

| Condition | ||

|---|---|---|

| Tenpereture | Hopper | 180℃(180-240℃) |

| Cylinder | 250℃(230-280℃) | |

| Nozzle | 240℃(220-280℃) | |

| Mold | 80℃ ( 70-100℃) | |

In case of CP101,Cylinder and nozzle temperature is recommended to be 230 ℃.

| Condition | ||

|---|---|---|

| Temperature | Hopper | 180℃(180-240℃) |

| Cylinder | 250℃(230-280℃) | |

| Die | 240℃(220-280℃) | |

| Roll | 80℃ ( 70-100℃) | |

In case of CP101, Recommended cylinder temperature is 230℃ and die temperature is 220 ℃.

Medical Amorphous Polyolefin Zelas™ CP

View the products of Performance Polymers Dept., Mitsubishi Chemical[Open in a new window]

This is the end of this page