- Industrials & Medical Films Dept.

Mitsubishi Chemical Corporation -

TEL:[+81]3-6748-7328

Super Engineering Plastic FilmSUPERIO™ UT

Mitsubishi Chemical Corporation

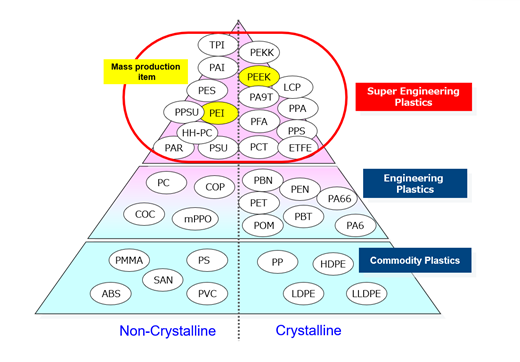

At Mitsubishi Chemical, we offer the high-performance engineering plastic film "SUPERIO™ UT". Leveraging our many years of accumulated technology and experience, we are currently mass-producing films made from PEI (polyetherimide) and PEEK (polyether ether ketone). These films have been adopted across a wide range of industries and applications, including automotive, electronics, and aerospace. To meet the increasingly diverse needs of our customers, we are actively engaged in the development and commercialization of an even broader range of high heat-resistant films. We also offer customized solutions tailored to specific customer requirements. If you are interested in high-performance engineering plastic films, please feel free to contact us.

Properties

[Close]

We have over 30 years of experience in the mass production and development of high heat-resistant super engineering plastic films.

In addition to the PEI and PEEK films currently in mass production, we have a proven track record in film production using various other resins.

Examples: PPSU, PA9T, PEKK, PES, and others

- Excellent heat resistance

- Excellent Chemical resistance

- Oil resistance

- Hydrolysis resistance

- Electrical properties

Tracking resistance and dielectric strength - Secondary processability (e.g., thermoforming, impregnation)

- Customizable thickness (from 3 to 350 μ)

Applications

[Close]

SUPERIO™ UT takes advantage of the superior heat resistance and additional properties of super engineering plastic films. And it is used across a wide range of fields as outlined below.

-

- Process ability

- Heat resistance

- Chemical resistance

- Heat dimensional stability

Aircraft components (CFRTP)

-

-

- Process ability

- Heat/Oil resistance

- Electrical properties

- Tracking resistance

Insulating materials for EV and air mobility

-

- Heat resistance

- Chemical resistance

- Dimensional stability

Tape substrates for semiconductors

-

- Process ability

- Heat resistance

- Hydrolysis resistance

- Humidity heat resistance

Energy-related components

-

- Process ability

- Heat resistance

- Chemical resistance

- Low water absorption

Diaphragm for Automotive and smart phone

-

- Heat resistance

- Chemical resistance

- Dimensional stability

Electronics

(VR goggles,3D printer)

Technical data

[Close]

| Resins | PEI | PPSU | PEEK | PI | PEN | PPS | ||

|---|---|---|---|---|---|---|---|---|

| E-Type | F-Type | A-Type | X-1 Type | KN-Type | Commercial products | |||

| Heat resistance | ○ | ○ | ○ | ◎ | ◎ | ◎ | ○ | ○ |

| Dimensional stability @200℃ |

◎ | ◎ | ○ | ○ | ○ | ◎ | △ | × |

| Long term Heat resistance @200℃ |

× | ○ | ‐ | ‐ | ○ | ○ | × | △ |

| Water absorption | △ | △ | ◎ | ◎ | ◎ | × | ○ | ◎ |

| Stiffness (rigidity) | ○ | ○ | △ | △ | ○ | ○ | ◎ | ◎ |

| Elongation | ○ | △ | ○ | ◎ | ◎ | × | × | × |

| Hydrolysis resistance | × | × | ◎ | ◎ | ◎ | × | × | ○ |

| Acid resistance | △ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

| Alkali resistance | △ | ○ | ○ | ○ | ○ | × | △ | ○ |

| Chemical resistance | △ | ○ | △ | ○ | ○ | ○ | ○ | ○ |

| UV transmission | × | × | ○ | △ | × | × | △ | × |