Market-leading Cling Film for Commercial Food Packaging DIAWRAP™

- Language

What is DIAWRAP™?

DIAWRAP™ is a cling film for commercial food packaging that is available in both polyolefin and PVC types.

Thick rolls (stretch film)

It has elasticity and is used for tray packaging of fresh food in supermarkets and processing centers.

DIAWRAP™ SUPER, DIAWRAP™

Thin rolls

For hotels and restaurants

DIAWRAP™ Clear Film, etc.

DIAWRAP™ Structure

PVC film (single layer)

By incorporating a special additive into the PVC resin, the required functions can be added to the cling film despite there only being a single layer.

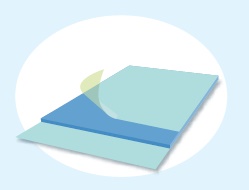

Polyolefin film (multilayer)

By adding a special function to each layer in the structure, the whole of the film combined has the required functions for cling film.

A Wide-ranging Lineup to Cater to the Diverse Needs of the Food Industry

DIAWRAP™ is a cling film designed for commercial food packaging that is used in an array of businesses such as supermarkets, food processing plants, restaurants, and hotels. This leading brand boasts a 35% share of the commercial-use cling film market and is available in two material varieties: polyvinyl chloride (PVC) film and multilayer polyolefin film. DIAWRAP™ is available in thick rolls that are predominantly used for automatic packaging machines as well as thin rolls for ease of use. Its diverse product lineup caters to a wide range of customer needs.

Due to the material’s characteristics, the PVC film boasts outstanding stretch ability and self-adhesive properties. Mitsubishi Chemical has built strong relationships with automatic packaging machine manufacturers due to the excellent compatibility of the thick rolls, which in turn has propelled the product’s growth. With many competitors offering only PVC film, MCC has also enhanced its competitive advantage by the development of a multilayer polyolefin film.

While the development of thick rolls of polyolefin films for packaging machines presented numerous challenges, Mitsubishi Chemical examined a variety of material combinations and adopted a multilayer film structure that was both as stretchable and difficult to tear as PVC film, while exhibiting similar material characteristics. In 1997, Mitsubishi Chemical was the first in the industry to release a non-PVC, polyolefin stretch film, DIAWRAP™ SUPER. The product achieved steady growth, and today is a leading product both in its accomplishment as well as popularity. The same multilayer technology was adopted in the production of DIAWRAP™ Clear Film a thin roll version of the polyolefin film — that features an aroma-retaining and heat-resistant middle layer.

An increasing amount of cling film has been used as demand for takeaway and food deliveries increased. With a lower specific gravity than PVC film, polyolefin film contributes to waste reduction as it generates up to one third less waste than PVC film.

DIAWRAP™ Blue Colored Film

Utilizing the multilayer structure—which was made possible by the company's advanced technological capabilities— Mitsubishi Chemical released a blue-colored cling film, DIAWRAP™ Blue Colored Film in 2013. Realizing that natural food products did not contain anything blue, Mitsubishi Chemical developed a blue-colored cling film to easily detect any pieces of cling film that might inadvertently make their way into the food during the work process. The blue was included in the middle layer to ensure it didn't come into direct contact with the food. The product is increasingly used in the meal service industry, where there is a particular focus on safety and security.