- Industrials & Medical Films Dept.

Mitsubishi Chemical Corporation -

TEL:[+81]3-6748-7328

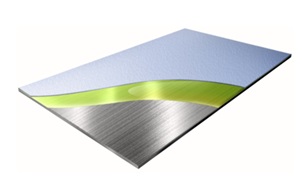

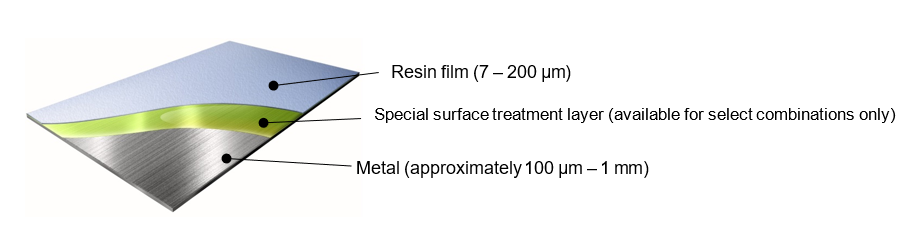

Metal-Resin Film Laminated MaterialALSET™

Mitsubishi Chemical CorporationA high‑performance composite that bonds metal and plastic film under extreme pressure—no adhesives required.

Key Features

- Pure Mechanical Lamination

Metals and polymer films are fused through a proprietary process, delivering exceptional peel strength and durability without resin or adhesive layers. - Custom Combinations

Choose your ideal metal + film pairing, thickness and finish to match your exact specifications. - Broad Compatibility

- Metals:

- Aluminum、Stainless steel (SUS)、Electro galvanized steel (SECC)、Zn-Al-Mg alloy (ZAM)

[under development]Copper - Resin Films:

- Polyamide (PA)、Polypropylene (PP)、Ultra high molecular weight polyethylene (UHMWPE)、Fluoropolymers、PET (polyethylene terephthalate)

[under development]PC 、PBT 、PPS、PEI

Specifications & Custom Orders

- Width: up to 500 mm max.

(Actual maximum depends on metal type and thickness—please inquire for details.) - Thickness & Layering: fully customizable—mix and match metal and film layers as needed.

- Special Requests: if you don’t see your preferred metal or film listed, please contact us—many additional materials can be accommodated.

Thickness, Configuration

[Close]

Rigid / Flexible Laminated Busbar Applications

[Close]

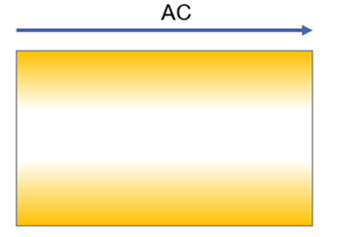

Under high-frequency AC conditions, current in a solid copper busbar tends to concentrate near the surface due to the skin effect. This reduces the effective cross-sectional area through which current can flow, resulting in higher AC resistance and greater heat generation (temperature rise).

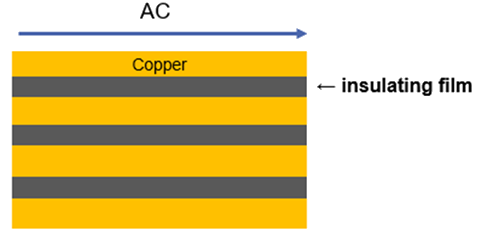

By laminating ALSET™, a metal–resin film composite material, in a metal/resin/metal/resin/metal... structure, the impact of the skin effect can be significantly reduced. This design lowers AC resistance, promotes more uniform current distribution, and helps suppress heat generation.

ALSET™ laminated busbars are available in both rigid and flexible configurations, offering excellent performance and design versatility for a wide range of power electronics and high-frequency applications.

Conventional copper busbar

Almost no current flows in the central region

➡High AC resistance = High heat generation

- Laminated busbar

Copper thickness of each layer < skin depth

Less affected by the skin effect

➡Low AC resistance = Low heat generation

Standalone Applications of ALSET™

[Close]

ALSET™ metal–resin film laminate is produced without adhesives, eliminating concerns over adhesive cohesive failure during processing and enabling metal‐like workability.

Features

- Eliminates the separate insulation‐film lamination step

- Eliminates metal coating/painting processes

- Enables miniaturization and space savings (reduced creepage distance)

- Delivers both electrical insulation and heat dissipation (versus pure resin)

Typical Applications

Capacitor housings; battery and electronic component cases; and other precision enclosures.

Thermal Welding Applications

[Close]

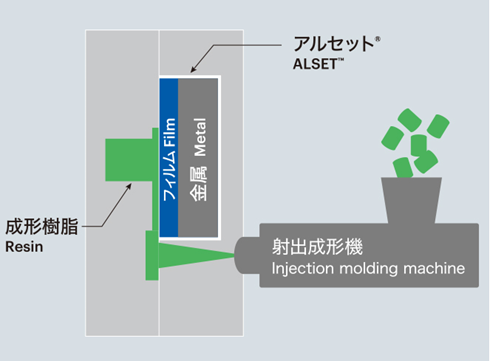

By choosing appropriate pellets and a heat weldable film for the resin layer of ALSET™, you can thermally weld metal and resin together using only the heat of your injection molding tool. No pretreatment of either the metal or the resin is needed, streamlining your process.

Features

- Composite metal and resin using heat alone

- Achieve lightweight metal components

- Impart electromagnetic shielding properties to the resin

- Enhance the resin’s heat dissipation performance

Typical Applications

Electromagnetic shielding components (e.g., inverter housings)

Thermal welding Sample Examples

[Close]