Polyolefin-based plastic film-laminated steel sheetsHISHIMETAL™ PO

Mitsubishi Chemical Infratec Co.,Ltd.- Language

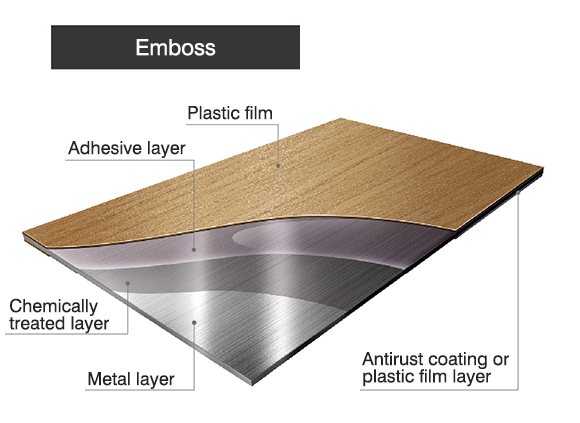

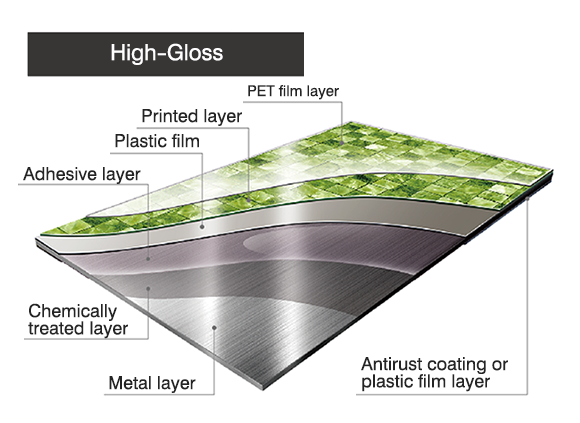

HISHIMETAL PO incorporates galvanized steel sheets, stainless steel sheets, and aluminum alloy sheets as a base material.

HISHIMETAL PO is a composite material produced by laminating a polyolefin-based film onto the base material.

This material is used for interior and door etc.

Mitsubishi Chemical Infratec【HISHIMETAL PO】[Open in a new window]

Characteristics

[Close]

- This material can be customized with the same variety of patterns and embossings as with PVC.

- This material has excellent chemical and solvent resistance.

Applications

[Close]

- Interior applications

Curtain rails, closets, etc. - Exterior applications

Doors, etc. - Light electrical appliances

- Other

Manufacturing Range and Order Conditions

[Close]

Lot

A lot of 2.5 tons or more is required to order a product having the same specifications such as the same sheet thickness, width, color and embossing.

- *Please order in lots of at least 2.5 tons as special request lots smaller than this will require an extra fee.

Lead times

The standard lead time is 30 to 45 days. This can vary depending on the specification of the order.

- *Specifications of new orders requires a confirmation procedure, and so we recommend placing new orders as early as possible.

Performance

[Close]

| Specific test | Test conditions | Criteria | HISHIMETAL PO | |

|---|---|---|---|---|

| Adhesion | Conformal Erichsen 6 mm extrusion |

25±5°C | No separation | Nothing abnormal |

| Bendability | Adhesion and bending test | 25±5°C, 0 T | No cracking, breakage, and separation |

Nothing abnormal |

| Processability at low temperature |

90° bend test | 0±1°C, R=2 | No cracking, breakage, and separation |

Nothing abnormal |

| Resistance to boiling water | Dipping in boiling water | Submerged in water for 5 minutes after 60 minutes of immersion |

No shrinkage, cracking, breakage, creasing, separation, and marked fading | Nothing abnormal |

| Chemical resistance | 5-minute immersion (20±2°C) |

10% hydrochloric acid | No rust, stain, and marked fading | Nothing abnormal |

| Saturated calcium hydroxide | ||||

| 10% sulfuric acid | ||||

| Aqueous solution of sodium hydroxide (100 g/L) | ||||

| Ethanol | ||||

| Kerosene | ||||

| Corrosion resistance | Complies with salt spray test JIS Z 2371 |

JIS K 6744 Type B: 1,000 hours |

No rust | Nothing abnormal |

- *1 The data described above represents the specified values in our company and does not represent guaranteed values.

- *2 Please contact us to inquire on the certification of fire-resistant materials.

Inquiries Concerning Products

View the products of Mitsubishi Chemical Infratec[Open in a new window]