Mitsubishi Synthetic Silica

- Mitsubishi Chemical Corporation

Semiconductor Materials Dept.

These are links for moving within this page

The semiconductor manufacturing process environment is becoming more rigid as devices become more miniaturized and stacked.

Mitsubishi Synthetic Silica is an ultra-pure raw material(7N) that has fewer metal impurities and bubbles typically found during the semiconductor manufacturing process.

Prevents particle generation in the manufacturing process.

Especially applicable to heat treatment, etching, and deposition processes, which can have adverse metal and impurity contamination during the manufacturing process.

We are dedicated to improving and developing optimum solutions as society's dependency on broadband, information technologies and green energy evolves.

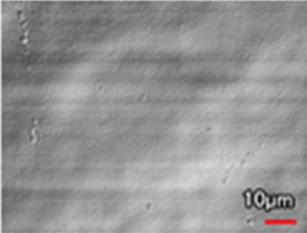

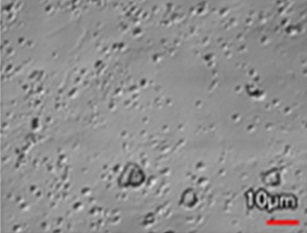

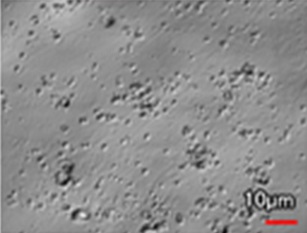

Compared to base materials manufactured from other existing products, the quartz surface is less rough after etching tests, and particle generation can be suppressed.

Improves process environment cleanliness during semiconductor manufacturing.

Able to develop and manufacture customized solutions based on customers operating environment specifications.

For more information, please contact us.

Product 【Mitsubishi Synthetic Silica】

Mitsubishi Synthetic Silica

This is the end of this page