High thermal conductive BN sheet

Mitsubishi Chemical Corporation- Language

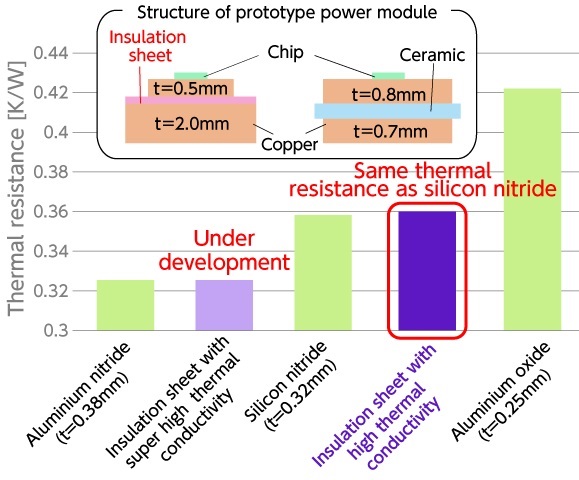

Proprietary BN fillers which have features of high thermal conductivity and isolation are packed into the resin sheet at high density. High-purity epoxy resin is developed and used as binder. It is suitable for power modules used in inverters, and achieves both thermal resistance and isolation equivalent to those of ceramic plate (in-house measurement result).

Features

[Close]

High thermal conductivity, high isolation performance

Proprietary BN fillers which have features of high thermal conductivity and isolation are packed into the resin sheet at high density. High-purity epoxy resin is developed and used as the binder. High heat conduction paths are secured by the optimized composition of the filler and the resin. Furthermore, high isolation voltage is achieved by less charge transfer resulting from high purity epoxy and void-less manufacturing process. As the results, it achieves both thermal resistance and isolation equivalent to those of ceramic plate.

(2in1 IGBT module,chip size=64mm2)

High reliability through small warpage and less-soldering

Coefficient of thermal expansion (CTE) of resin sheet was optimized as the same level as that of copper. As the results, IMS (Isulated Metal Substrate) keeps small deformation & warpage over the temperature change and it can make amount of soldering & grease much less in jointing.

Copper can be designed much thicker and IMS design without a base plate is available. These advantages contribute not only the cost reduction but also improvement of reliability.

Module lamination structure

This product can be used for bonding power modules such as transfer molded power module to metal plate. This resin sheet can perform the three functions of insulation, heat dissipation and adhesion. It contribute to improved module reliability and total cost benefits.

Large-sized IMS and easy for design

Large-sized IMS is realized because of optimization of CTE. Overall process cost reductions can be expected through flexibility in module design and simplified mounting process.

Characteristics

[Close]

| P/N | SH-A206 | SH-A204 (under development) |

|---|---|---|

| Thermal conductivity (Typical) | 16.5W/mK (ASTM D5470) | 15W/mK (ASTM D5470) |

| Isolation voltage (Typical) | 8kV AC | 8kV AC |

| UL94 | V-0 | TBD |

| Remark | for IMS/IMB. Recommendation : Upper copper (t=0.5mm) / BN sheet (t=0.15mm) / Lower copper (t=2mm) |

for module lamination structure |

Inquiries Concerning Products

View the products of Semiconductor Div., Mitsubishi Chemical[Open in a new window]