- Mitsubishi Chemical Corporation

- Membrane Business Gr.Separation Materials Dept.

-

TEL:[+81]-3-6748-7429

These are links for moving within this page

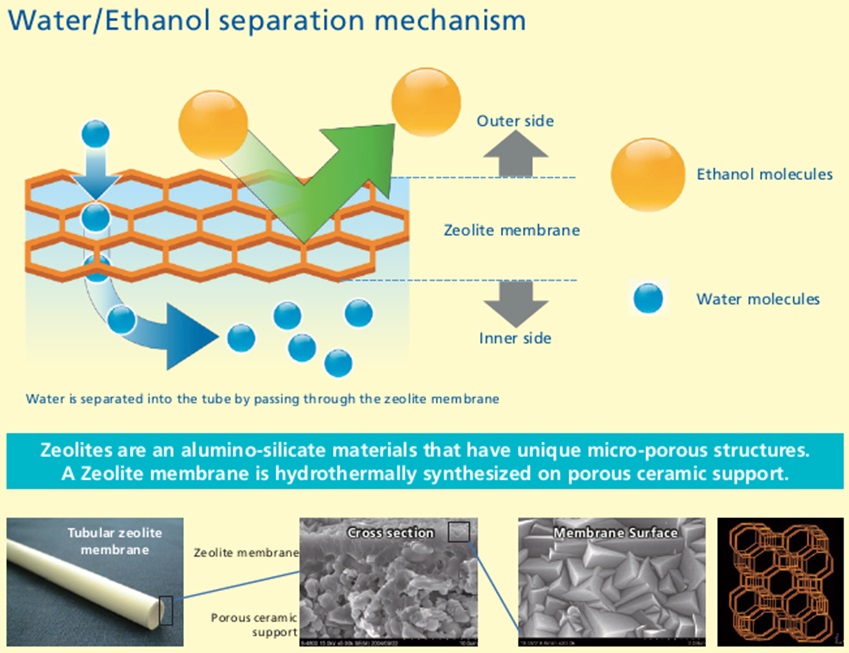

ZEBREX™ is cutting-edge zeolite membrane dehydration process, which can dehydrate solvents under a wide range of water concentration and pH conditions, and is a one-pass continuous process rather than a batch process.

ex.) Ethanol, Isopropanol, Acetone, Methyl Ethyl Ketone, Tetrahydrofuran, etc.

[Close]

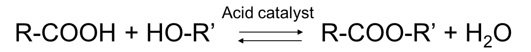

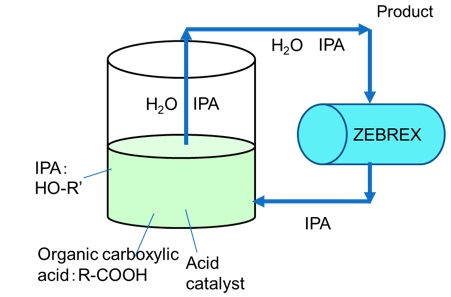

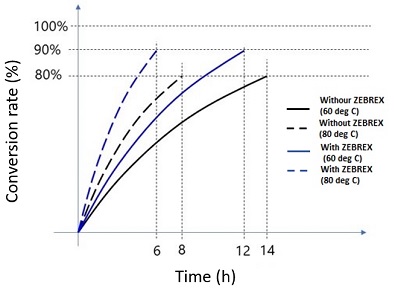

Some reactions such as an esterification generate water during the reaction. For example, in the esterification reaction, presence of water puts the reaction in equilibrium. In general, process engineers use distillation / PSA for dehydration. However, operation of distillation / PSA is complicated for customers because the amount of water produced changes over time. ZEBREX™ can contribute to shorten takt time and easy operation. Moreover, ZEBREX™ can improve its yield. This technology is now in practical application stage.

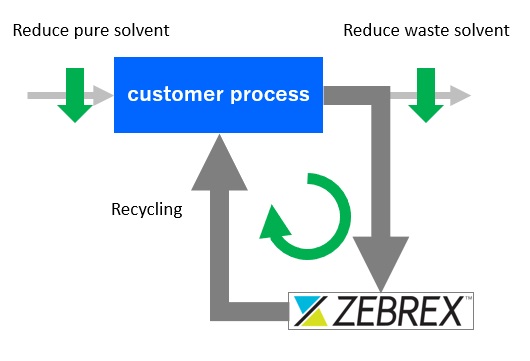

We contribute recycling at customer site by ZEBREX™. For example, cost of dehydrated solvent is roughly 10 JPY/kg (About 0.1 USD/kg) in some cases.

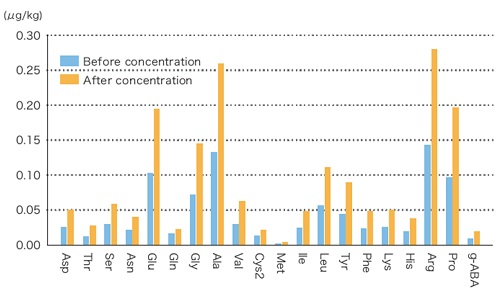

Dehydration at low temperature enables concentration that retains flavor, aroma, and active pharma Ingredients. For example, dehydration of Japanese sake in an atmosphere of room temperature, dehydration of ethanol in atmosphere of 50 to 60 degree C (atmospheric pressure) to very low water concentration, etc. We have conviction that this technology will contribute to development of new customers products.

[Close]

ZEBREX™ customers are in industries of chemical (inorganic and organic), pharmaceutical, alcohol, bioethanol, beverage, waste solvent treatment, electronics and engineering.

Topic

Mitsui Engineering & Shipbuilding Co., Ltd. (Current Mitsui E&S Holdings Co., Ltd. ) launched world’s first zeolite membrane dehydration system.

Mitsubishi Chemical Corporation commercialized CHA type zeolite membrane, named ZEBREX™ ZX1.

Mitsui Zosen & Machinery Service Inc. (Current Mitsui E&S power systems Inc.) and Mitsubishi Chemical Corporation made business alliance about zeolite membrane. Unified brand name is ZEBREX™ (Industrial grade) and KonKer™ (Food grade).

Mitsubishi Chemical Corporation commercialized acid resistance zeolite membrane for bio ethanol industry, named ZEBREX™ ZX2.

The business alliance between Mitsui E&S Power Systems Inc. and Mitsubishi Chemical Corporation was terminated.

[Close]

[Close]

| Industrial grade | ZEBREX™ ZX1 | ZEBREX™ ZX2 |

|---|---|---|

| Acid resistance | High | Medium |

| Water resistance | High | Medium |

| Flux | Medium | Medium |

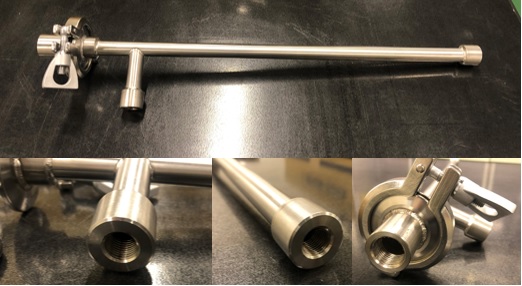

Installing one zeolite membrane which length is 40cm (15.75 inch)

TEL:[+81]-3-6748-7429

View the products of Separation Materials Dept., Mitsubishi Chemical[Open in a new window]

This is the end of this page