Products

Thermoset Carbon Fiber Prepreg

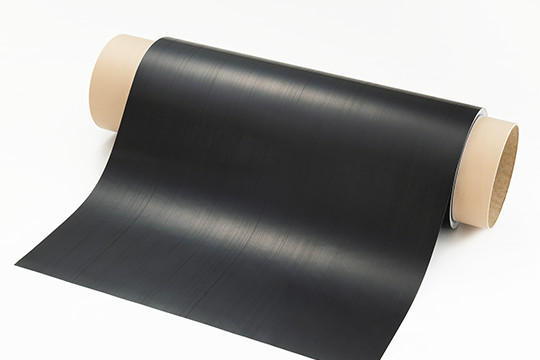

Thermoset Carbon Fiber Prepreg is an intermediate material in the form of a sheet of carbon fiber impregnated with thermoset matrix resin. There are various types of prepreg such as UD prepreg (unidirectional prepreg), in which carbon

fibers are aligned in one direction, and cloth prepreg, in which carbon fibers are woven into a fabric and impregnated with matrix resin.

▶ Please see this page about thermoplastic carbon fiber prepreg.

In-page menu

Features

Mitsubishi Chemical offers a wide range of prepreg products, including UD prepreg, cloth prepreg, and special prepreg.

For prepreg consisting of carbon fiber and thermoset matrix resin, it is necessary to select the most suitable carbon fiber and resin for the particular application.

Mitsubishi Chemical has developed various of its own thermoset matrix resin to meet the needs of different application, enabling it to offer prepregs of various characteristics, such as rapid curing, heat resistance, and high toughness.

Applications

UD prepreg takes advantage of the anisotropic nature of carbon fiber to greatly expand the range of product design, by placing the necessary prepreg in the right place at the right time.

Cloth prepreg offers excellent drape property, making it well suited to creating shapes that follow the contours of product. Due to its good “designability,” it is also very well suited for exterior applications.

Product Lineup

UD Prepreg (Unidirectional) Prepreg

| Product name |

Carbon fiber type |

Resin type | Carbon fiber weight (Fiber areal weight) (g/m2) |

Resin content (RC)(wt%) |

Prepreg weight (Prepreg areal weight)(g/m2) | Thickness (mm) |

Std. Length (m) |

|---|---|---|---|---|---|---|---|

| TR 350C075S | PAN 24t | High-toughness epoxy | 75 | 25 | 100 | 0.062 | 125 |

| TR 350C100S | PAN 24t | High-toughness epoxy | 100 | 25 | 133 | 0.083 | 125 |

| TR 350C125S | PAN 24t | High-toughness epoxy | 125 | 25 | 167 | 0.103 | 125 |

| TR 350C150S | PAN 24t | High-toughness epoxy | 150 | 25 | 200 | 0.124 | 125 |

| TR 350C175S | PAN 24t | High-toughness epoxy | 175 | 25 | 233 | 0.145 | 125 |

| TR 350E100R | PAN 24t | High-toughness epoxy | 105 | 30 | 150 | 0.095 | 125 |

| TR 350E125S | PAN 24t | High-toughness epoxy | 125 | 30 | 179 | 0.113 | 125 |

| TR 350E150S | PAN 24t | High-toughness epoxy | 150 | 30 | 214 | 0.136 | 125 |

| TR 350G100S | PAN 24t | High-toughness epoxy | 100 | 33 | 149 | 0.096 | 125 |

| TR 350G125S | PAN 24t | High-toughness epoxy | 125 | 33 | 187 | 0.120 | 125 |

| TR 350G150S | PAN 24t | High-toughness epoxy | 150 | 33 | 224 | 0.144 | 125 |

| TR 350G175S | PAN 24t | High-toughness epoxy | 175 | 33 | 261 | 0.168 | 125 |

| TR 350G250S | PAN 24t | High-toughness epoxy | 250 | 33 | 373 | 0.240 | 75 |

| TR 350J050S | PAN 24t | High-toughness epoxy | 54 | 37.5 | 86 | 0.057 | 125 |

| TRH350B100S | PAN 26t | High-toughness epoxy | 100 | 20 | 125 | 0.080 | 125 |

| TRH350B125S | PAN 26t | High-toughness epoxy | 125 | 20 | 156 | 0.095 | 125 |

| TRH350B150S | PAN 26t | High-toughness epoxy | 150 | 20 | 188 | 0.114 | 125 |

| MRX350C075S | PAN 30t | High-toughness epoxy | 75 | 25 | 100 | 0.062 | 125 |

| MRX350C100S | PAN 30t | High-toughness epoxy | 100 | 25 | 133 | 0.083 | 125 |

| MRX350C125S | PAN 30t | High-toughness epoxy | 125 | 25 | 167 | 0.104 | 125 |

| MRX350C150S | PAN 30t | High-toughness epoxy | 150 | 25 | 200 | 0.125 | 125 |

| MR 350J050S | PAN 30t | High-toughness epoxy | 54 | 37.5 | 86 | 0.057 | 125 |

| MRA350C075S | PAN 33t | High-toughness epoxy | 75 | 25 | 100 | 0.062 | 125 |

| MRA350C100S | PAN 33t | High-toughness epoxy | 100 | 25 | 133 | 0.083 | 125 |

| MRA350C125S | PAN 33t | High-toughness epoxy | 125 | 25 | 167 | 0.103 | 125 |

| HRX350C075S | PAN 40t | High-toughness epoxy | 69 | 25 | 92 | 0.057 | 125 |

| HRX350C080S | PAN 40t | High-toughness epoxy | 75 | 24 | 99 | 0.061 | 125 |

| HRX350C100S | PAN 40t | High-toughness epoxy | 92 | 25 | 123 | 0.076 | 125 |

| HRX350C110S | PAN 40t | High-toughness epoxy | 100 | 24 | 132 | 0.081 | 125 |

| HRX350C125S | PAN 40t | High-toughness epoxy | 116 | 25 | 155 | 0.096 | 125 |

| HRX350C130S | PAN 40t | High-toughness epoxy | 125 | 24 | 164 | 0.102 | 125 |

| HRX350C150S | PAN 40t | High-toughness epoxy | 139 | 25 | 185 | 0.115 | 125 |

| HRX350C160S | PAN 40t | High-toughness epoxy | 150 | 25 | 200 | 0.124 | 125 |

| HSX350C075S | PAN 46t | High-toughness epoxy | 69 | 25 | 92 | 0.056 | 125 |

| HSX350C080S | PAN 46t | High-toughness epoxy | 75 | 24 | 99 | 0.060 | 125 |

| HSX350C100S | PAN 46t | High-toughness epoxy | 92 | 25 | 123 | 0.075 | 125 |

| HSX350C110S | PAN 46t | High-toughness epoxy | 100 | 24 | 132 | 0.080 | 125 |

| HSX350C125S | PAN 46t | High-toughness epoxy | 116 | 25 | 155 | 0.095 | 125 |

| HSX350C130S | PAN 46t | High-toughness epoxy | 125 | 24 | 164 | 0.100 | 125 |

| HSX350C150S | PAN 46t | High-toughness epoxy | 139 | 25 | 185 | 0.114 | 125 |

| HSX350C160S | PAN 46t | High-toughness epoxy | 150 | 24 | 197 | 0.121 | 125 |

| Product name |

Carbon fiber type | Resin type | Carbon fiber weight (Fiber areal weight) (g/m2) |

Resin content (RC)(wt%) |

Prepreg weight (Prepreg areal weight)(g/m2) | Thickness (mm) |

Std. Length (m) |

|---|---|---|---|---|---|---|---|

| HyE J10M65PD | PITCH 65t | General-purpose epoxy | 100 | 35 | 154 | 0.094 | 100 |

| HyE J17M65QD | PITCH 65t | General-purpose epoxy | 175 | 32 | 257 | 0.150 | 100 |

| HyE J34M65PD | PITCH 65t | General-purpose epoxy | 340 | 32 | 500 | 0.292 | 50 |

| HyE J12M80QD | PITCH 80t | General-purpose epoxy | 125 | 20 | 156 | 0.084 | 100 |

| HyE J12M80QD | PITCH 80t | General-purpose epoxy | 125 | 25 | 167 | 0.092 | 100 |

| HyE J12M80QD | PITCH 80t | General-purpose epoxy | 125 | 37 | 198 | 0.118 | 100 |

| HyE J28M80QD | PITCH 80t | General-purpose epoxy | 280 | 32 | 412 | 0.240 | 50 |

| HyE J56M80QD | PITCH 80t | General-purpose epoxy | 560 | 32 | 838 | 0.480 | 30 |

| HyE J34M65PDHX1 | PITCH 65t | Heat-resistant epoxy | 340 | 30 | 486 | 0.280 | 75 |

| HyE J28M80QDHX1 | PITCH 80t | Heat-resistant epoxy | 280 | 30 | 400 | 0.229 | 50 |

| HyE J45M80QDHX1 | PITCH 80t | Heat-resistant epoxy | 450 | 30 | 643 | 0.367 | 50 |

| HyE J17HX1 SG | PAN 24t | Heat-resistant epoxy | 175 | 30 | 250 | 0.158 | 100 |

| HyE J25HX1 SG | PAN 24t | Heat-resistant epoxy | 250 | 30 | 357 | 0.225 | 75 |

The values in this table are typical values

and do not imply an kind of guarantee. If you would like to use a resin in the list of resins listed separately, please contact us.

The width of all types of prepreg is 1,000 mm. The standard length is displayed for winding lengths. If you would like a non-standard length, please contact us.

Cloth Prepreg (Fabric Prepreg)

| Product name | Carbon fiber type | Fabric structure | Resin type | Carbon fiber weight (Fiber areal weight) (g/m2) |

Resin content (RC)(wt%) |

Prepreg weight (Prepreg areal weight)(g/m2) | Thickness (mm) |

Std. Length (m) |

|---|---|---|---|---|---|---|---|---|

| TR3110 381GMX | PAN 24t | Plain | High-appearance epoxy | 200 | 40 | 333 | 0.22 | 50 |

| TR3523 381GMX | PAN 24t | 2/2 twill | High-appearance epoxy | 200 | 40 | 333 | 0.22 | 50 |

| TR6110H331GMP | PAN 24t | Plain | General-purpose epoxy | 288 | 40 | 480 | 0.32 | 50 |

| TRK101 331GMP | PAN 24t | Plain | General-purpose epoxy | 400 | 40 | 667 | 0.44 | 50 |

| TRK510 321GMP | PAN 24t | 2/2 twill | General-purpose epoxy | 646 | 40 | 1,077 | 0.72 | 25 |

| Product name | Carbon fiber type | Fabric structure | Resin type | Carbon fiber weight (Fiber areal weight) (g/m2) |

Resin content (RC)(wt%) |

Prepreg weight (Prepreg areal weight)(g/m2) | Thickness (mm) |

Length (m) |

|---|---|---|---|---|---|---|---|---|

| HMFJ3113/911H | PAN 24t | Plain | Heat-resistant epoxy | 200 | 45 | 364 | 0.25 | 50 |

The values in this table are typical values

and do not imply an kind of guarantee. If you would like to use a resin in the list of resins listed separately, please contact us.

The width of all types of prepreg is 1,000 mm. The standard length is displayed for winding lengths. If you would like a non-standard length, please contact us.

Prepreg Matrix Resin List

| Resin number |

Resin type | Curing temperature (ºC) |

Main applications | Features |

|---|---|---|---|---|

| #350 | Epoxy | 130 | General applications, sporting goods | High toughness |

| #381 | Epoxy | 130 | Cloth prepreg, general purpose | Transparent appearance |

| #392 | Epoxy | 130 | General applications, sporting goods | Rapid curing |

| #395 | Epoxy | 130 | General applications, sporting goods | Rapid curing, high toughness |

| #361 | Epoxy | 130-140 | Industrial, automotive exterior components | Press molding (PCM), rapid curing, class A appearance |

| #368 | Epoxy | 130-140 | Industrial, automotive exterior components | Press molding (PCM), rapid curing, heat resistance |

| #3R1 | Epoxy | 130-150 | Industrial, automobiles | Press molding (PCM), ultra-rapid curing, heat resistance |

| #830 | Epoxy | 80 | General applications, sporting goods | Low-temperature curing |

| #853 | Epoxy | 80 (demolding) 180 (post-curing) |

Industrial, aerospace tools (mold materials) | Low-temperature curing, demoldable Heat resistance (post-curing), low thermal expansion |

| #261 | Epoxy | 180 | General applications, general industrial | Heat resistance, transparent appearance |

| #270 | Epoxy | 180 | Industrial, aerospace tools (mold materials) | Heat resistance, low thermal expansion |

| #266 | Epoxy | 180 | General industrial | Heat resistance, toughness |

| #290 | Cyanate ester | 135 (demolding) 250 (post-curing) |

Industrial, aerospace | High heat resistance |

| #108 | Epoxy | 180 | Aerospace | Heat resistance, toughness |

Please consult with us for other specifications.