Performance Polymers Technology Center

Mitsubishi Chemical Corporation

①TEFABLOC™ QE with enhanced scratch and abrasion resistance

TEFABLOC™ QE series has been developed with unique formulation and compounding technology to achieve better scratch and abrasion resistance with smooth surface finishing without treatments such as painting and coating.

Applications: automotive interior skin such as instrument panel, console, grip, knob.

②Polymer/Elastomer with excellent blood compatibilities

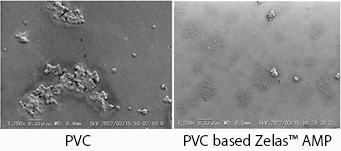

We have developed Zelas™ AMP with hemocompatibility for plasma, platelets. Zelas™AMP can impart hemocompatibility to thermoplastic resins such as vinyl chloride resin (PVC) for blood tubing and bags, TPU for catheter and PP/PMMA for laboratory supplies and diagnosis.

Zelas™AMP is a revolutionary technology that allows thermoplastic resins to be made blood-compatible through normal processing processes (injection, extrusion), eliminating the need for coating processes.

Cooperation of Professor Masaru Tanaka, Soft Materials Chemistry, Institute for Materials Chemistry and Engineering, Kyushu University

https://www.m-chemical.co.jp/en/products/departments/mcc/mcpp/expo/1214423_7758.html

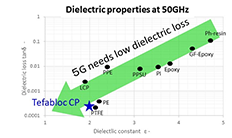

③Material with low dielectric loss

We developed Tefabloc™ CP with low dielectric loss for use in high-speed communication applications such as 5G and 6G .We are able to customize products according to the requests.

We have also developed metal-adhesive and solvent-soluble grades using resin-modification technology, and design products in line with customer requirements.

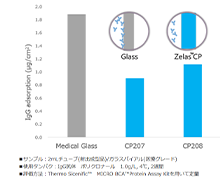

④Zelas™ CP with low adsorption performance of low molecular weight pharmaceuticals/biopharmaceuticals

Using our compound formulation techniques, we have developed Zelas™ CP, which adsorbs less proteins such as antibodies (IgG) and plasma (Fibrinogen). Zelas™ CP also show low adsorption with low molecular drugs.