Advanced Materials Technology Center

Mitsubishi Chemical Corporation

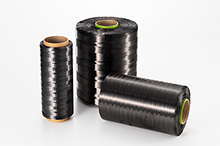

①High quality, high performance carbon fiber

PAN-based carbon fiber

Mitsubishi Chemical is the carbon fiber manufacturer that produces both PAN-based and pitch-based carbon fibers. We have been improving the quality and performance of our carbon fibers by sophisticating the raw materials and manufacturing conditions for these materials. This carbon fiber is used in a wide range of fields, from aerospace and automobiles to sporting and leisure goods.

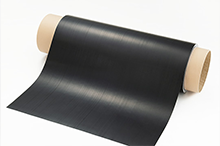

②Intermediate material for carbon fiber reinforced composites

Prepreg (UD)

FMC™ (CF-SMC)

We develop intermediate materials for carbon fiber composite materials represented by prepreg and FMC™ (CF-SMC). These intermediate materials can achieve various physical properties and applications by combining carbon fiber and resin. For this reason, we has already developed intermediate materials with features such as fast curing, heat resistance, high toughness, and high moldability, and in recent years, we have been focusing on plant-derived resins for prepreg.

③Composite parts and their forming process

Prepreg molding

Hollow molding

We design stacking sequence, charge patterns, and molding processes to maximize component performance and mass production. This allows us to provide solutions that meet our customers' requirements. In recent years, we have also developed our own prepreg compression molding(PCM), hollow molding(FCM), and surface treatment technologies.

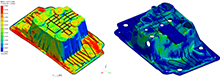

④Computer simulations

(Left)Fiber orientation

(Right)Dynamic fracture

We utilize FEA and CFD to optimize part design and molding processes. For example, in FMC™ (CF-SMC), physical properties change significantly due to fiber orientation that occurs during molding. Therefore, by mapping fiber orientation analysis and mechanical properties, it is possible to predict part performance.

⑤Evaluation of physical properties and performance

Digital image correlation (DIC)

We have abundant facilities for evaluating static, dynamic, and long-term properties, as well as thermal and viscoelastic performance. We also integrate mechanical measurements with DIC or acoustic emissions to simultaneously capture the evolution of deformation and fracture. The consistency with simulations are also evaluated.

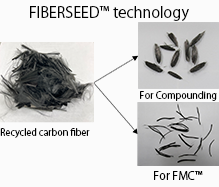

⑥Recycling technology

FIBERSEED™ technology enables us to form fleece-like recycled carbon fibers into bundles aligned in one direction. We are applying this technology not only to compounding applications but to FMC using recycled carbon fibers.