MMA

From KAITEKI Report 2023 issued in September 2023

Build a solid global No. 1 position

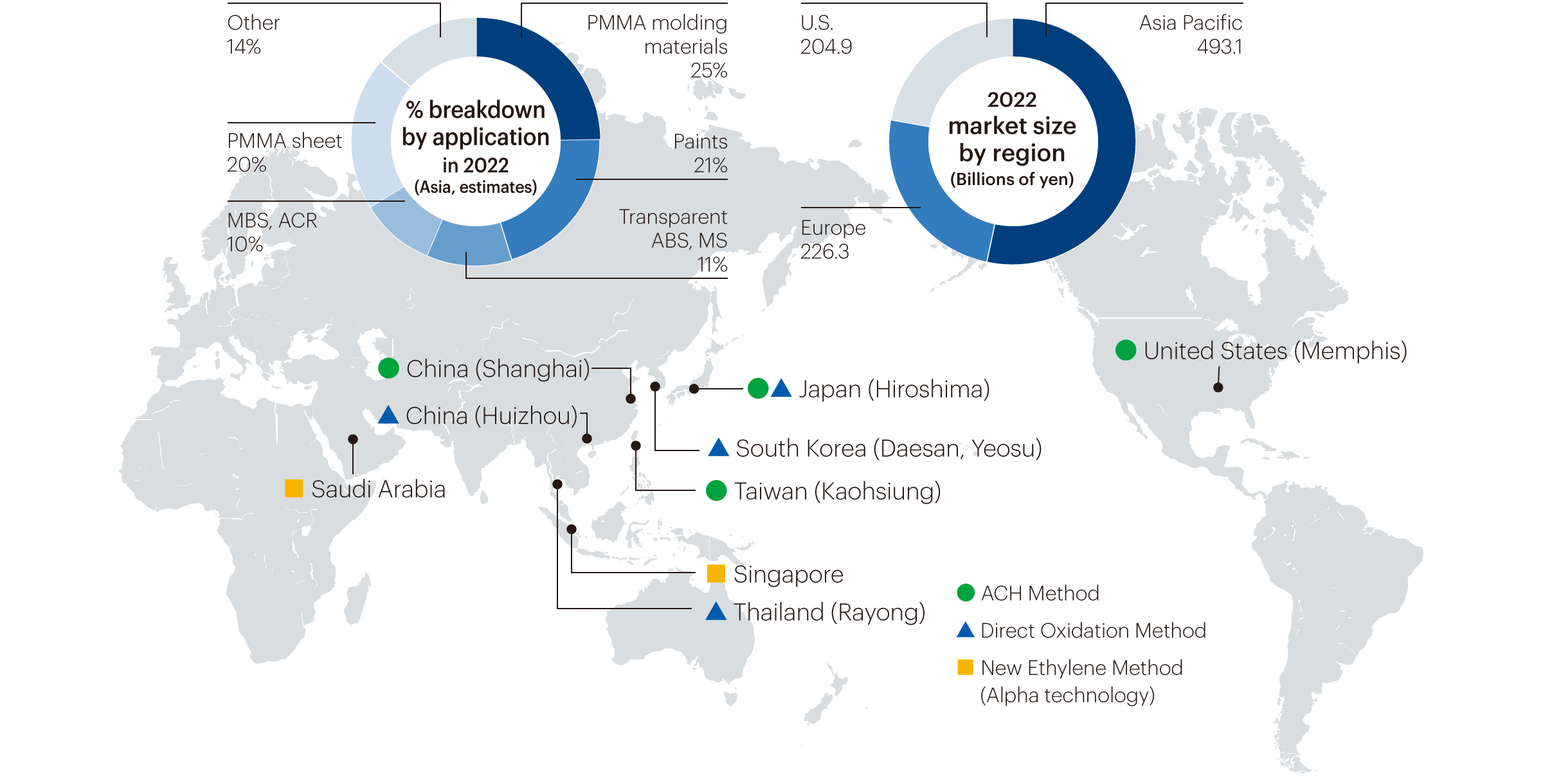

MMA is used for a wide range of applications, including cars, building materials, displays, transparent sheets, and coatings. Demand is expected to rise steadily in line with each country’s GDP. The MCG Group has capabilities in all three main MMA manufacturing methods, including the new ethylene method (Alpha technology) that is the most cost competitive, and is equipped with the world’s largest capacity. We aim to leverage this potential to build a solid global No. 1 position. At the same time, we are working to develop PMMA recycling technology and bio-MMA monomer to contribute to a circular economy.

Strategic focus

- Boost productivity, improve raw material access, and leverage the best technology through an optimized footprint of new facilities

- Benefit from lower demand volatility in the United States

- Strengthen the sustainability focus based on existing PMMA recycling and bio-MMA

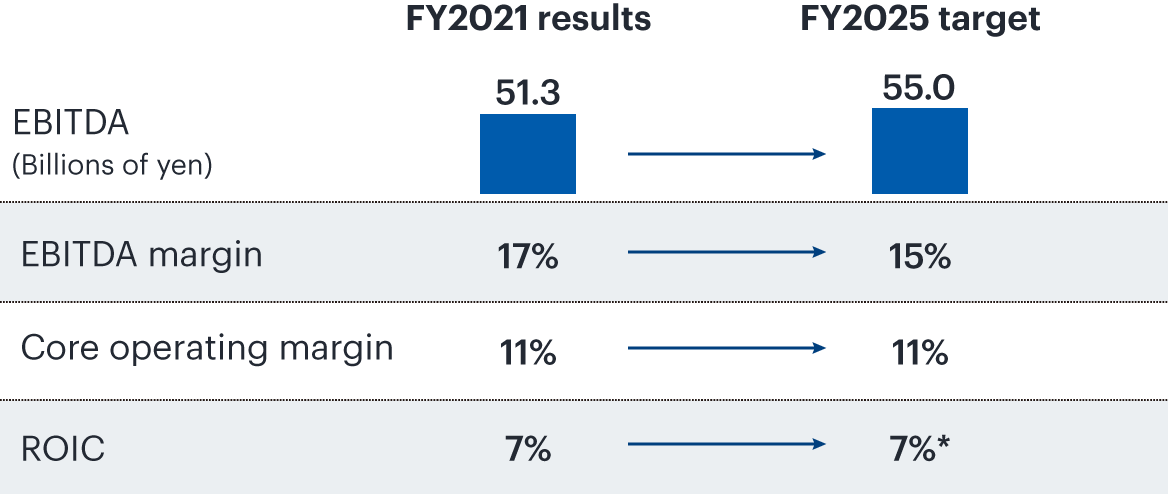

- *Includes the effect of partially complete large investment in a U.S. facility; ROIC excluding the investment is 9%.

SWOT analysis

Strengths

Strengths

- Three manufacturing methods (and the only company worldwide with the new ethylene method called Alpha technology)

- Top share of the global MMA market at around 30%

Weaknesses

Weaknesses

- Fluctuating earnings due to global market conditions

- Fluctuating earnings due to raw material prices

Opportunities

Opportunities

- Business operation network capable of meeting growing global demand

Threats

Threats

- Competition from alternative materials

- Emergence of new, highly competitive manufacturing methods

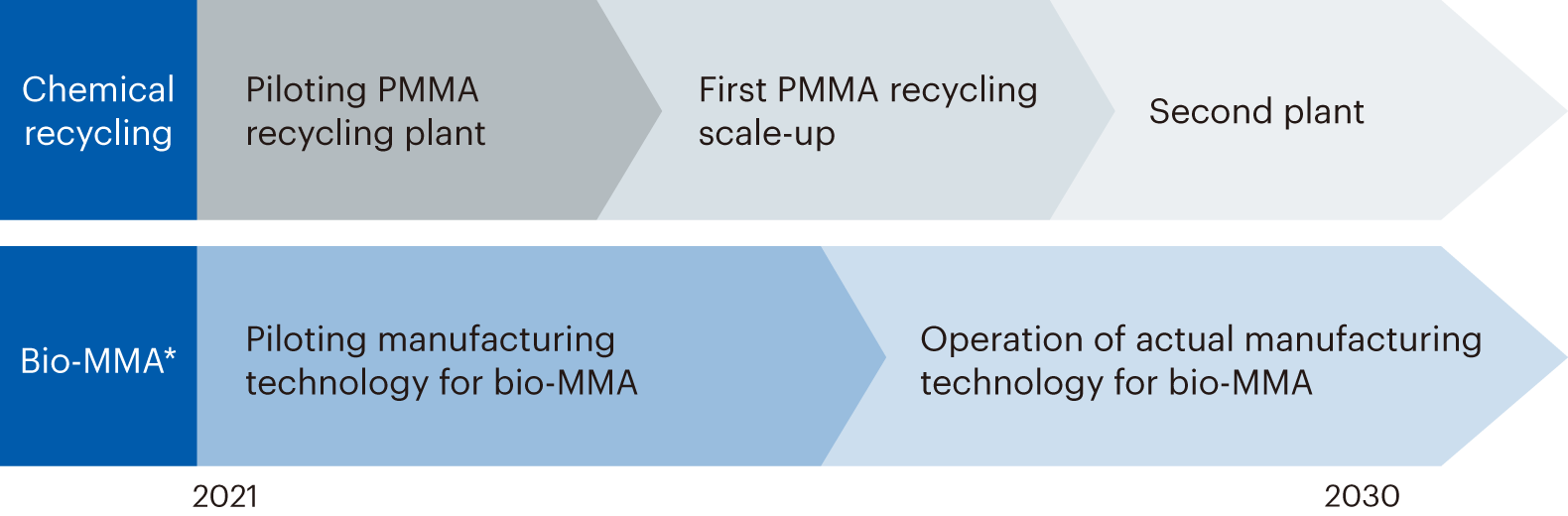

Expanding the sustainable MMA portfolio

The MCG Group defines “sustainable MMA” as MMA monomer manufactured through (1) chemical recycling, where used acrylic resin is collected and broken down for reuse; (2) new manufacturing technologies that use bio-based raw materials with existing MMA monomer production processes; or (3) entirely new manufacturing technologies that use fermentation of bio-based raw materials to produce MMA monomer directly. We are working to develop these technology approaches to MMA manufacturing.

For approach (1), we constructed pilot facilities in Japan in June 2021 and are running tests ahead of commercialization. We have also made progress in the technology development for approach (2) and are now designing a new pilot plant. We will start operating the pilot plant in fiscal 2023 to test the technology and product quality, with the goal of applying this technology to existing commercial-scale plants in 2026. We will take an active lead in initiatives to realize a circular economy by reducing the environmental burden right across the supply chain.

- *Refers to approach (2) in the text above