Supply chain

The Chemicals Industry Unites to Pursue

Joint Logistics (Part 2)

March 21, 2024

/ TEXT BY MCG

*The information, positions and affiliations mentioned in this interview reflect the status at the time of the interview.

*"Mitsubishi Chemical Group" and "Mitsubishi Chemical Group (MCG)" refer to Mitsubishi Chemical Group Corporation and its group companies.

Four companies gathered to exchange ideas on joint logistics in Japan’s chemicals industry: the Mitsubishi Chemical Group, Mitsui Chemicals, Tosoh, and Toray. They are members of the secretariat in the Chemicals Working Group, which is part of the Physical Internet Realization Council led by the Ministry of Economy, Trade and Industry and the Ministry of Land, Infrastructure, Transport and Tourism. In Part 1, we covered the need for joint logistics, the background behind the working group's creation, and its organization. Part 2 includes discussions on the topics the working group is addressing and what's coming next for the group. Let's learn more about what's in store for the industry-wide joint logistics effort. <Back to part 1>

-

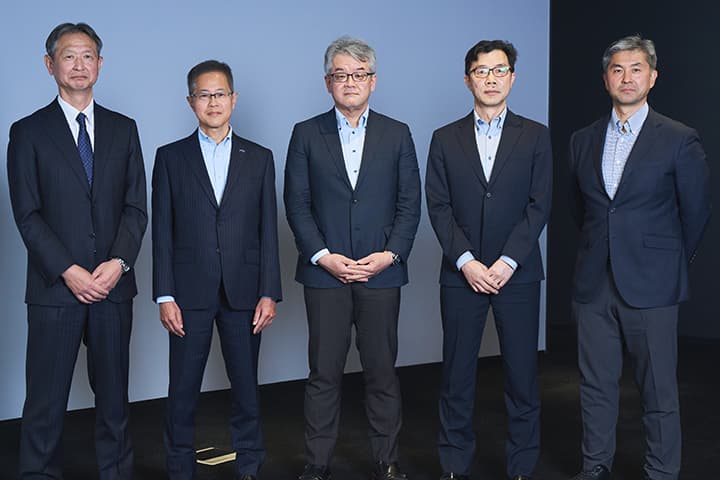

■Members(From left to right)

Hidenori YuriLogistics Group Leader, Purchasing & Logistics Department, Tosoh Corporation

Tomoyuki SuitsuGeneral Manager, Logistics Department, Purchasing & Logistics Division, Toray Industries, Inc.

Kaoru YoritaGeneral Manager, Logistics Division, Digital Transformation Sector, Mitsui Chemicals, Inc.

Hiroshi OshimaGeneral Manager, Strategy & Management Department, Procurement & Logistics Division, Supply Chain, Mitsubishi Chemical Group

Toshiki HayashiGeneral Manager, Logistics Promotion & Support Department, Procurement & Logistics Division, Supply Chain, Mitsubishi Chemical Group

Two goals: implementing “sustainable logistics” and improving business practices

The Chemicals Working Group started with an unprecedented sense of purpose and expectation. The group is engaged in discussions covering a diverse range of issues and solutions, with as many as 19 subcommittees actively involved. The participants spoke about how the group's efforts will extend beyond simply sharing and collaborating on logistics resources.

Suitsu, Toray: A critical issue tied to the 2024 problem is implementing “sustainable logistics,” which refers to better working conditions for people in the industry. Many initiatives are underway to reduce the workload on drivers and create a more conducive working environment. Toray leads the Cargo Wait Time Subcommittee, comprising approximately 20 chemical manufacturers, including industry associations. The Japanese government's issued guidelines primarily emphasize three points: 1) understanding cargo wait times, 2) limiting waiting times to two hours (or one hour if already achieved), and 3) allocating equipment to enhance the efficiency of cargo loading and unloading operations.

In addition to keeping track of time, many companies are trying to reduce cargo wait times by introducing reservation systems to enter factories. One Toray factory has even reduced wait times from one hour to about 15 minutes. Given the circumstances, one logistics firm said it would be inefficient for each company to introduce its own system. Lively discussions that are open to multiple perspectives are precisely what the Chemicals Working Group wants. We are also now considering the selection of a chemicals industry recommendation system.

Additionally, it's important to improve the flow of traffic and berths at factories, ensure that proper cargo handling machinery and personnel are in place, and consider relaxing or eliminating designated delivery times for arrivals and departures. These are some of the issues we need to consider. However, there are cases in which a cargo wait time limit of two hours may be problematic, such as when it impedes a driver from being present with a truck. Looking ahead, we intend to hold discussions with government agencies to individually consider ways to reduce cargo wait times by replacing the time limits with some other methods. It is also our mission to consider how to adapt operations to the nature of our industry.

Tomoyuki Suitsu, General Manager, Logistics Department, Purchasing & Logistics Division, Toray

Oshima, Mitsubishi Chemical Group: One important initiative is the palletization*1 and mechanization of labor-intensive manual handling. For example, Japan has an estimated 130,000 women with licenses to drive large vehicles, but only about 8,000 of them are working as drivers. One reason for this situation is assumed to be the significant physical burden of labor-intensive manual loading and unloading. We believe that creating a work environment with automation and mechanization will contribute to achieving “sustainable logistics” and addressing the labor shortage in distribution networks.

Yuri, Tosoh: Improving business practices. I believe this is the most crucial part of the Chemicals Working Group's work. To improve working environments, we must improve the current business practices that chemical manufacturers and delivery destinations have been following, such as what drivers must do upon delivery, designated delivery times like first thing in the morning, and so on. And these improvements must be implemented in a manner that is acceptable to all three parties: recipients, logistics firms, and chemical manufacturers.

Oshima, Mitsubishi Chemical Group: Our relationships with our customers who receive our goods will be the key factor to success in achieving the goals of implementing “sustainable logistics” and improving business practices. I believe each company has made various proposals from their own standpoints. However, proposals by individual companies have had their limits. Now we can express our opinions as the consensus of the Chemicals Working Group. Putting forth stronger proposals is one significant aspect of the value provided by the Chemicals Working Group.

Hiroshi Oshima, General Manager, Strategy & Management Department, Procurement & Logistics Division, Supply Chain, Mitsubishi Chemical Group

Yuri, Tosoh: In December 2023, the Chemicals Working Group announced a voluntary course of action for the 2024 problem. Based on that, we are currently developing an action plan that runs until 2030. We intend to start by engaging with the industry associations to which our corporate customers belong, using this action plan as a foundation.

The importance of achieving standardization and DX (Digital Transformation)

Hayashi, Mitsubishi Chemical Group: The importance of palletization has come up in our discussion, and when we consider the next step after palletization, one could be standardization to enhance the efficiency of pallet operations. Chemical products come in various forms such as liquids, powders, and gases, and there are many types of packaging materials, so we need different pallets for each type of cargo. Moreover, pallet standards differ from company to company. In discussions on optimizing pallet operation, we are exploring the concept of eventually renting pallets instead of owning them. And in terms of load efficiency, it is better to operate without adding more pallet types. In Japan, where the working-age population is declining, palletization is an indispensable solution for conserving our limited human resources. On the other hand, changing pallets requires investment. It also requires the time to study each company's packing and filling conditions, storage locations, delivery locations, and other factors. Given that the Chemicals Working Group comprises companies keenly aware of the necessity for reform, I think we have created an environment conducive to collaboration toward standardization.

Yorita, Mitsui Chemicals: There's another essential theme for us in driving logistics reforms, and that is digital transformation, or DX. The use of digital technology is crucial to initiatives we've been talking about, such as operating reservation systems for trucks entering factories or standardizing pallets and equipment. I also expect we'll make great progress exploring joint logistics themes, as well as in matching cargo, means of transportation, and routes by employing digital technology. In the near future, we are also considering the development of a substantial platform that contributes to joint logistics. With a digital platform, rather than relying on the knowledge of the personnel in charge and manual calculations, we will fully achieve a modal shift*2 to rail and sea transportation.

Kaoru Yorita, General Manager, Logistics Division, Digital Transformation Sector, Mitsui Chemicals

The future resulting from promotion of joint logistics today

The Chemicals Working Group's action plan will be incorporated into a series of short-, medium-, and long-term activity plans. The chemicals industry will continue transformation for logistics as we organically intertwine physical and digital initiatives over the short, medium, and long term. How does the Chemicals Working Group, established as the standard-bearer of transformation, envision the future?

Oshima, Mitsubishi Chemical Group: The Chemicals Working Group is positioned as a subcommittee within the Physical Internet Realization Council led by the Ministry of Economy, Trade and Industry and the Ministry of Land, Infrastructure, Transport and Tourism. Our vision is to implement the ultimate joint logistics scheme across industries between 2030 and 2040. For our part, we intend to work hard to achieve this goal. One of the primary objectives of joint logistics is to enable the transport of more cargo with fewer assets and personnel to increase load efficiency. This in turn increases sales per truck, lowers cost per ton, and, from an environmental standpoint, reduces greenhouse gas emissions. As a result, I believe that logistics firms, shippers, and society will all benefit.

Yuri, Tosoh: Our collaborative efforts, stemming from the 2024 problem, will evolve toward establishing a sustainable chemicals industry. Firstly, I believe it's crucial to prioritize addressing the labor shortage and tackling various challenges, starting with improving our business practices. Some of these issues may take a long time to work out, but I hope we can achieve more favorable outcomes not only through the efforts of individual companies, but also through the collaboration of the entire Chemicals Working Group.

Hidenori Yuri, Logistics Group Leader, Purchasing & Logistics Department, Tosoh

Suitsu, Toray: I think it's important for each company to view the 2024 problem as its own concern while also working together to establish a sustainable logistics system within the industry. For example, if we can improve load efficiency across the industry, it will lead to further reductions in greenhouse gas emissions. In other words, it will contribute to green logistics. Through this working group, we have paved the way for collaboration between companies. I believe that collaborative efforts across the chemicals industry will extend beyond our sector, promoting progress towards achieving carbon neutrality.

Yorita, Mitsui Chemicals: Today, the four companies of the Chemicals Working Group secretariat have been discussing our thoughts on joint logistics. I believe that our ultimate goal is for the term "joint logistics" to become obsolete. We aim to standardize streamlined logistics across the entire industry, which will mean that logistics will not be an issue anymore. That is the future we aspire to, and I really hope it will be realized in 2030.

Toshiki Hayashi, General Manager, Logistics Promotion & Support Department, Procurement & Logistics Division, Supply Chain, Mitsubishi Chemical Group

Hayashi, Mitsubishi Chemical Group: I consider this working group to be a medium- to long-term initiative. I'd like to involve the next generation in this initiative and aim to build a sustainable logistics system. To achieve this, it is very important to develop young talent. Here in the chemicals industry, we're positioned upstream of many other industries, so we may not have a conspicuous public presence or attract so much attention. However, without our chemicals, many of the products that support people's lives would not be created. Our products support the foundations of life in society and the competitiveness of various industries, business sectors, and companies. By promoting joint logistics in Japan, we can maintain Japan’s chemicals industry supply chain, which in turn will support all industries. We shall continue to encourage collaboration while retaining this determination in mind.

The chemicals industry, which supports a number of other industries, is uniting to co-create joint logistics. This will significantly improve business practices and create new possibilities that would have been difficult for individual companies to achieve. By walking together and developing together, the initiatives to create a sustainable logistics system will spread beyond the chemicals industry and lead to a brighter future.

- *1 Palletization: Goods are loaded onto pallets and distributed on a pallet-by-pallet basis. Distribution with cargo loaded onto the same pallet from departure point to destination is called intermodal palletization.

- *2 Modal shift: The transition from freight transport by trucks and other automobiles to the use of rail and ships, which have a smaller environmental impact.