The lunar rover YAOKI's exterior-crafted almost entirely by the Group:

Learn why they're deeply invested in outer space

Dec 04, 2023

/ Article on Business Insider Japan

*This English text is a translation of a document originally prepared in Japanese.

*The information, positions and affiliations mentioned in this interview reflect the status at the time of the interview.

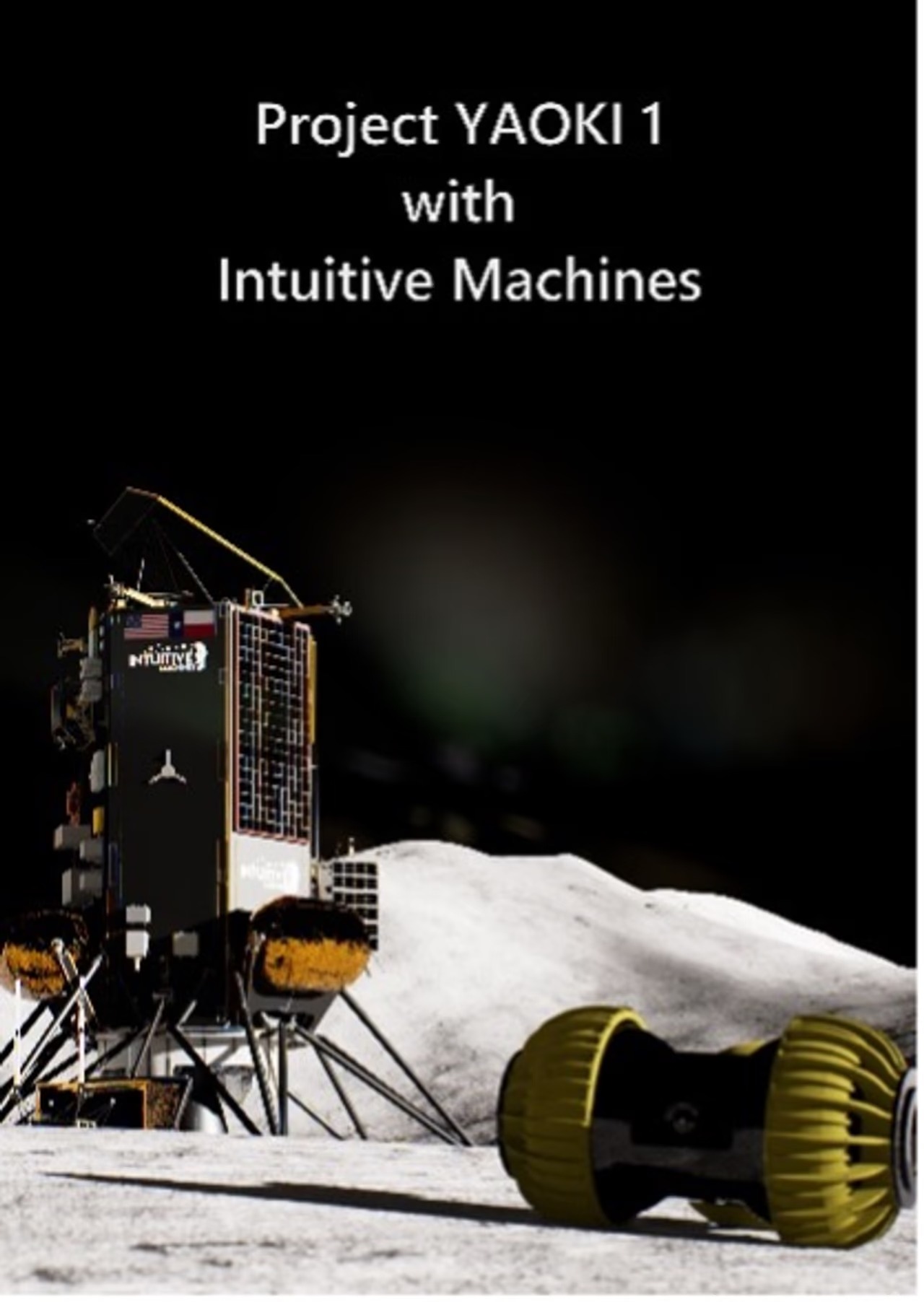

Startup company Dymon seeks to be the first private company in the world and the first Japanese enterprise to explore the Moon. Dymon Co., Ltd. developed YAOKI, the smallest, most lightweight lunar rover, which will go to the Moon in early 2024. After landing on the lunar surface, the vehicle will be remotely operated from Earth to travel around the Moon's south pole for several hours of exploration.

The Mitsubishi Chemical Group (the MCG Group) is a partner behind this tremendous first step. A chemical manufacturer with global reach and world-leading technologies, the MCG Group provides innovative solutions in a wide range of fields. In a collaboration with Dymon that began in 2021, the Group has supported YAOKI's development by supplying carbon fiber-reinforced plastic (CFRP) materials and thermoplastic materials, as well as technical support.

How does YAOKI use the Group’s materials and technologies? And where will this collaboration between the Group and Dymon lead? Dymon’s Shinichiro Nakajima chatted with the Group’s Akira Nakagoshi and Rie Nishida about the nature of the partnership and the role of the materials manufacturer.

Space to become a 300-trillion-yen business by 2050.

The private sector-led space business is picking up steam. According to a research report by MUFG Bank, the global space market is expected to grow from 56 trillion yen in 2023 to 91 trillion yen in 2030. Meanwhile, one forecast projects it will grow to 150 trillion yen by 2040 and 300 trillion yen by 2050.

Given this bullish outlook, the lunar business is one part of the space industry attracting the most interest for its potential.

Akira Nakagoshi, who is in charge of composite products for the mobility market and is involved in the MCG Group’s space business, provided some background. "It started when former President Trump signed the Space Policy Directive (SPD) in December 2017. Later, in March 2019, when the National Space Council held its fifth meeting, it came out with a policy of conducting a manned lunar landing by 2024. To accomplish this, NASA's budget has since grown, more companies have become involved, and competition is intensifying."

This led to NASA announcing the Artemis Program, which seeks to carry out a manned lunar landing by 2024 and to commence construction of a lunar base by 2028. Space development shifted from the traditional government-led approach as NASA introduced Commercial Lunar Payload Services (CLPS), by which the space agency will pay private companies to transport observation equipment, rovers, and other cargo to the Moon.

Dymon, a venture firm specializing in robot and space technology development, is participating in CLPS and has developed the lunar rover YAOKI.

Image courtesy of Dymon

YAOKI comes from the Japanese proverb “Nanakorobi Yaoki”.

This word means “to get back up again and again, no matter how many times you fail”.

And, as the proverb goes, YAOKI is designed to rise no matter how many times it fall.

YAOKI's greatest feature is its incredibly compact size and light weight.

"Generally speaking, transportation to the Moon costs 100 million yen per kilogram. With dimensions measuring 15 x 15 x 10 cm and weighing only 498 grams, YAOKI is incredibly small and lightweight, making it inexpensive to transport. We plan to take advantage of that to send a large number of YAOKI rovers to the Moon, where they will survey the lunar surface while communicating and coordinating with each other."

So says Dymon CEO Shinichiro Nakajima, who developed YAOKI. His goal is to explore caves because they can provide humans with refuge from radiation, meteorite strikes, and the extreme temperature fluctuations between the lunar day and night.

He added, "I think that YAOKI is presently the world's only lunar rover capable of surveying caves. It is equipped with a camera and sensors. Controllers on Earth will operate it to navigate caves and determine their shape and size. We are now working with JAXA to make this a reality."

The secret behind YAOKI's shape and impressive strength lies in the fact that it is the only lunar rover outfitted for cave exploration. Even if it falls over, YAOKI is designed to immediately return to its normal position and continue traveling. It can also withstand impacts of up to 100 G (1 G = acceleration due to gravity on Earth), allowing it to tumble down into caves. The MCG Group is supporting this ultra-lightweight, high-strength design with cutting-edge materials and technologies.

Three materials from the MCG Group that advanced the evolution of YAOKI

YAOKI is built with three cutting-edge materials and technologies developed by the MCG Group. One, in the main unit, is CFRP made of cyanate ester resin.

Nakagoshi says, "Originally, YAOKI's main unit was going to be aluminum, but it was replaced with CFRP due to its strength and lightness. Applying CFRP made of cyanate ester resin, which delivers low permittivity and excellent temperature resistance, makes it suitable for aerospace applications. This made the main unit about 30% lighter and reduced the cost of transportation to the Moon by around 4 million yen per unit. The increased strength has enhanced the safety factor, which has now improved by a factor of five."

Second is the polyamide-imide (PAI), employed in the wheels. This material has excellent cold and heat resistance, wear resistance, and impact strength. The YAOKI rovers will be transported to the Moon in a deployer (i.e., case) stored on the lunar lander's exterior.

When the lunar lander touches down on the Moon, the deployer will open, allowing the YAOKI rovers to drop onto the lunar surface. Thanks to the use of PAI, they can withstand the impact of this fall. Incidentally, the deployer itself is also made of cyanate ester resin CFRP supplied by the Group.

The third is an anti-soiling coating agent that prevents regolith, or lunar sand, from clinging to the camera lens. Rie Nishida, who is engaged in market development for the MCG Group’s coating business, explains:

“Regolith adheres easily due to its jagged, thorny shape and electrostatic properties. If it were to stick to a camera lens, it would obstruct the view of the lunar surface, causing issues during exploration. Working with the development team, we conducted tests in our laboratory on our coating agents and suggested one to help prevent regolith from clinging. After Dymon conducted their own rigorous testing, the challenges were overcome, and they decided to adopt our coating agent.”

Dymon’s Nakajima adds, “As for the exterior, it’s no exaggeration to say it’s made almost 100% by Mitsubishi Chemical. They’re now essential to taking us to the Moon.”

The YAOKI rovers are expected to reach the surface of the Moon in early 2024. They will travel on an Intuitive Machines Nova-C Lunar Lander launched by a SpaceX Falcon 9 rocket and touch down near the Moon’s south pole. This is a NASA mission to search for water resources. After landing, 100 YAOKI rovers will deploy to the lunar surface and explore caves for the next three to five years.

YAOKI is building connections both within the company and externally to enhance the space business.

This is not the MCG Group's first foray into the space business, having supplied materials for satellites since long ago. It all began with the Cassini spacecraft.

Nakagoshi explains, "Our pitch-based carbon fiber was first used in the Cassini spacecraft that was launched in 1997. For the next two decades, it made great achievements observing Saturn. Later, our pitch-based carbon fiber was used in Hinode, JAXA's solar corona observation satellite, as well as a number of other Mars probes."

The knowledge gained from meeting the technical demands for the extreme conditions in outer space has been applied to projects down here on Earth.

For example, because it has zero thermal expansion, pitch-based carbon fiber was used for the ALMA Project, an international joint U.S.-European-Japanese project to explore deep space by constructing a number of large radio telescopes in Chile.

With a sense of pride, Nakagoshi says, "We aim to apply the knowledge gained through our space business collaborations on satellites and YAOKI to projects on Earth. That's indeed the embodiment of our slogan, "Science. Value. Life." We are dedicated to leading the realization of KAITEKI through better Science, by providing Value to all stakeholders and contributing to healthy living and the sustainable Life of people and the planet."

Nishida shares her enthusiasm for the challenges in outer space. "It's truly exciting. I want to work with Dymon on Moon missions to build on our achievements in space, and use that as an opportunity to develop new applications and businesses on Earth and in space."

What has the MCG Group gained from working with Dymon? Nishida says, "Since I became involved in the space business, my colleagues have been telling me I seem to be having lots of fun. It is in fact stimulating. If I can spread this feeling throughout the company and encourage younger employees to have similar experiences, it will change their impressions of the space business and the company's mood. I'm keeping that in mind in my work."

Nakagoshi stresses, "My goal is to foster collaborations both within and outside the company through the YAOKI Project. "

He adds, "Currently, we only provide CFRP and PAI for YAOKI's exterior, but the MCG Group also has expertise in semiconductors, which are the electronic components inside. Leveraging such science to deliver value, we want to collaborate on YAOKI with the collective strength of the Group across our business domains. This cross-functional collaboration extends beyond our own company. YAOKI partner companies regularly meet to exchange information. They visited the Science & Innovation Center, the Group's hub for mid- to long-term R&D, for technical exchanges with our R&D team. These opportunities serve as a platform for expanding our network and fostering collaboration with external parties."

The MCG Group is looking beyond these collaborations to the development of outer space, aiming to make it a new pillar of the Group’s business.

Nakagoshi says, “I believe there is significant potential for the MCG Group's materials and technologies to play an active part in the expanding space industry, such as with heat shield materials. If we can collaborate with American space development companies that move fast and execute well, there is a possibility for the space sector to become a new pillar in the Group's businesses. I want to forge the path that will lead us there."

The New Business Creation Project “Project Space” initiated by the MCG Group’s Polymers & Compounds/MMA Business Group and comprised of mid-career and young employees is actively working on themes associated with creating new value in the space business. One of the themes focuses on the efficient collection of plastic waste in the ocean using satellite data and recycling of collected plastic for space applications including satellites. Nishida is one of the project's members.

She mentions, "This year, space-related professions secured the tenth spot in the ranking of dream careers for first-grade boys in Japan. For me, space represents a venture into uncharted territories. However, space is undoubtedly a part of our children's future.

It is our role to pass it on to those generations as a business. I want to continue embracing challenges while involving younger people. If possible, I want to keep going until my later years."

Lastly, Nakajima shares his thoughts on space.

"So far, it feels like Japanese technology has often been utilized somewhat like a subcontractor in space development. Now, we are at the forefront of lunar exploration. Leveraging this fortunate position, we aim to become platform leaders. I hope YAOKI's achievements will serve as one of the catalysts for securing such a position."