Supply chain

The Chemicals Industry Unites to Pursue

Joint Logistics (Part 1)

March 21, 2024

/ TEXT BY MCG

*The information, positions and affiliations mentioned in this interview reflect the status at the time of the interview.

*"Mitsubishi Chemical Group" and "Mitsubishi Chemical Group (MCG)" refer to Mitsubishi Chemical Group Corporation and its group companies.

In recent years, work-style reform has prompted a reassessment of labor environments, and, starting from April 2024, truck drivers in Japan will be subject to an annual overtime limit of 960 hours. All companies face the urgent task of responding to what has been dubbed the 2024 logistics problem arising from a shortage of truck drivers that could stifle the flow of goods in distribution networks.

In July 2023, the chemicals industry voluntarily raised its voice and established a Chemicals Working Group within the Physical Internet*1 Realization Council led by the Ministry of Economy, Trade and Industry and the Ministry of Land, Infrastructure, Transport and Tourism. More than 70 companies, mainly shippers and logistics firms, have joined the group and begun reforming the chemical logistics system. Recently, four secretariat members—the Mitsubishi Chemical Group, Mitsui Chemicals, Tosoh, and Toray--gathered to discuss the significance of the chemicals industry implementing "joint logistics," their efforts to solve industry-specific issues, and the potential for expansion through co-creation.

-

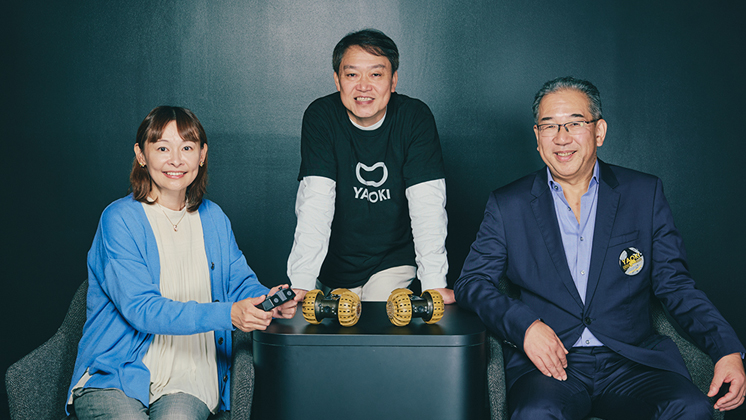

■Members(From left to right)

Hidenori YuriLogistics Group Leader, Purchasing & Logistics Department, Tosoh Corporation

Tomoyuki SuitsuGeneral Manager, Logistics Department, Purchasing & Logistics Division, Toray Industries, Inc.

Kaoru YoritaGeneral Manager, Logistics Division, Digital Transformation Sector, Mitsui Chemicals, Inc.

Hiroshi OshimaGeneral Manager, Strategy & Management Department, Procurement & Logistics Division, Supply Chain, Mitsubishi Chemical Group

Toshiki HayashiGeneral Manager, Logistics Promotion & Support Department, Procurement & Logistics Division, Supply Chain, Mitsubishi Chemical Group

Top priority in meeting joint logistics requirements: addressing the labor shortage

Oshima, Mitsubishi Chemical Group:With Japan's declining working-age population, the logistics industry faces significant challenges from aging drivers and a labor shortage. In addition, in response to the 2024 problem, the chemicals industry confronts the extremely important issue of how to ensure future transportation and storage capacity for its products.

Hiroshi Oshima, General Manager, Strategy & Management Department, Procurement & Logistics Division, Supply Chain, Mitsubishi Chemical Group

Yorita, Mitsui Chemicals:The labor shortage is not restricted to the logistics industry. Challenges such as the aging of logistics personnel and a shortage of manpower also emerge in other sectors. We are in manufacturing, and our business only works when we can safely transport products without delay and ensure that customers can use them. In other words, if labor shortages impair distribution functions, there will be a great impact on our business. Furthermore, chemical manufacturers supply materials to various industries. This means that a slowdown in the distribution of our products would disrupt various other industries as well. In this sense, we share a great sense of mission and responsibility with all industries.

Kaoru Yorita, General Manager, Logistics Division, Digital Transformation Sector, Mitsui Chemicals

Yuri, Tosoh:One solution to the labor shortage is to create a better working environment for women, the elderly, and anyone else who wants to work. This reform is also extremely important in terms of improving productivity. However, unlike general consumer goods, the chemical products we manufacture may be difficult to handle. They may include hazardous, toxic, or deleterious, or come in the form of high-pressure gas. And some of them are heavy and require machinery for transportation. There are limits to what individual companies can do to improve the working environment. I believe that industry-wide collaboration offers a more efficient approach to address these challenges.

Suitsu, Toray:When I talk to transportation managers at other companies, they often express difficulty in recruiting personnel, particularly young talent. The reason is the working conditions characterized by long hours and low wages, especially when compared to other industries. I believe that enhancing the working environment from the shipper's side to address these critical issues will contribute to boosting productivity within the logistics industry. Even during the logistics crisis of 2017, Toray promoted initiatives such as joint logistics, palletization, and modal shifts. To be honest, however, some of those joint logistics efforts were shelved once the crisis was over. With the impending enforcement of legislation for shippers to improve working conditions, companies must align their efforts and ensure a sustained commitment to this cause. In addition, initiatives including joint logistics and modal shifts aimed at improving load efficiency will directly lead to the reduction of greenhouse gas emissions in logistics. I see the 2024 problem as an opportunity to transform our approach to logistics and distribution, making improvements not only within the chemicals industry but also across other sectors.

A joint effort to tackle chemical logistics issues

Yorita, Mitsui Chemicals: Higher logistics costs are also an issue. Naturally, they have a significant impact on business operations, and we would like to hold ours down. On the other hand, it is also true that our business would not be possible without the understanding and support of the logistics companies we work with. It's important to manage the impact that logistics costs have and to control them properly. As for cost increases that individual companies cannot control, we want to promote joint logistics in cooperation with other companies to make efficient use of the logistics infrastructure and optimize costs. I hope we can work together on this.

Hayashi, Mitsubishi Chemical Group:In terms of load efficiency, even if it's difficult for one company to improve it, improvement can be achieved if multiple companies work together. That's why I think joint logistics is very significant.

Yuri, Tosoh:I'd like to go back to the topic of cost. Another key point is clarifying tasks. As I said before, we handle chemicals that include hazardous substances such as flammables, toxins, deleterious substances, and high-pressure gases. Therefore, it's essential to establish a safe work environment and correct the industry-specific business practices to ensure appropriate workloads for laborers. For example, in the case of using trucks, we may conclude a cargo handling agreement with the recipient and clarify the work details and standards. Since tasks come with a cost, clarifying the details also clarifies how costs are allocated. It is difficult for individual companies to make such improvements, so it's essential to establish industry-wide standards. However, long-standing business practices cannot be improved immediately, so I would like to take the time to talk with stakeholders and gain their understanding as we move forward. The working group includes major logistics firms, so we can hear their views as we proceed, which will be a significant advantage.

Hidenori Yuri, Logistics Group Leader, Purchasing & Logistics Department, Tosoh

Hayashi, Mitsubishi Chemical Group:In addition, one of the key points about the working group's significance is that it has established a platform for both shippers and recipients to exchange views. I think that continuous communication between shippers, recipients, and logistics companies will help build sustainable distribution networks.

The starting point of the Chemicals Working Group

What may be difficult for an individual company to achieve can be made more feasible through collaboration. The Chemicals Working Group was established in July 2023. How did it come to be and grow?

Hayashi, Mitsubishi Chemical Group:While joint logistics among individual companies has been practiced before, I think the starting point for a big wave like this is the Sustainable Logistics Declaration*2 made by various companies in response to government requests. The declaration came in anticipation of the 2024 problem, and since then, momentum has been building among companies. In the meantime, Mitsui Chemicals and the Mitsubishi Chemical Group began exchanging information on joint logistics in the autumn of 2021, which led to the launch of the Chemicals Working Group in 2023.

Toshiki Hayashi, General Manager, Logistics Promotion & Support Department, Procurement & Logistics Division, Supply Chain, Mitsubishi Chemical Group

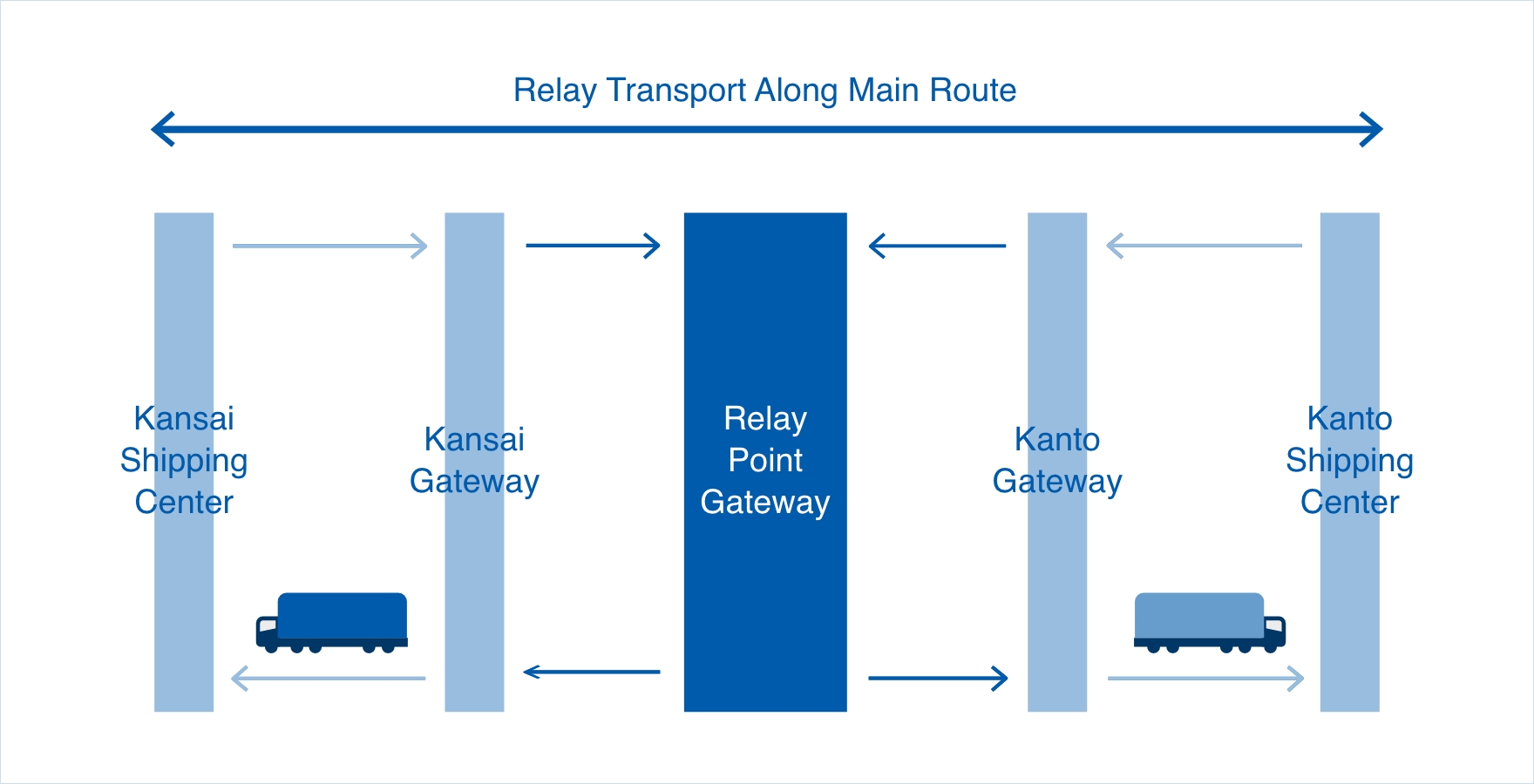

Yorita, Mitsui Chemicals:Yes, recognizing the challenge of advancing logistics reform by a single company, we began exchanging information in 2021, then conducted comprehensive studies on joint logistics in January 2023 before issuing a press release. We also aimed to create momentum for logistics innovation in the chemicals industry. Since the study commenced, concrete measures were undertaken between our two companies. For example, in June 2023, Mitsui Chemicals began utilizing the distribution network of the Mitsubishi Chemical Group spanning from the Chukyo to Kanto regions, and in July, the Mitsubishi Chemical Group began leveraging our network from the Kanto to the Tohoku regions. While network utilization in neighboring areas has occurred in the past, this is the chemicals industry's first instance of mutual utilization between companies over such distances.

Hayashi, Mitsubishi Chemical Group:We trialed "relay transportation," in which trailers are exchanged at intermediate points to reduce the workload on drivers. As the collaboration between our two companies progressed, we retained the strong sense of crisis that we alone cannot mitigate the inefficiencies, along with the unwavering sense of mission and responsibility that our products are the foundation for all other industries. This thinking led to the establishment of the Chemicals Working Group, which calls for broad participation from various companies that will lead to action, as well as the assumption of responsibilities by the secretariat.

Yorita, Mitsui Chemicals:Rather than only two companies considering joint logistics, I believe that if companies in the industry that are stuck on the same issues unite and pool their wisdom and knowledge, further possibilities and new solutions will emerge. With this in mind, we started looking for companies that would be willing to proactively participate.

Hayashi, Mitsubishi Chemical Group:Our two companies visited Tosoh in February 2023 and Toray in March 2023 to express our desire for them to join the secretariat with us. I remember that they were quite enthusiastic and very receptive to our request.

Yuri, Tosoh:At Tosoh, we had a sense of crisis that distribution would cease to function if we didn't take action. Cost reduction used to be at the center of discussions, but around 2015, the distribution labor shortage became apparent, so the focus of our internal discussions shifted to making distribution sustainable. While we had repeatedly exchanged ideas with other companies and engaged in joint logistics initiatives between individual companies, we came to strongly believe that we needed a major industry-wide effort to keep this activity going. It was precisely at this time that the Mitsubishi Chemical Group and Mitsui Chemicals approached Tosoh about joining the Chemicals Working Group and becoming a part of its secretariat. We accepted this opportunity with the determination to give it our best shot.

Tomoyuki Suitsu, General Manager, Logistics Department, Purchasing & Logistics Division, Toray

Suitsu, Toray:When we received the invitation from the Mitsubishi Chemical Group and Mitsui Chemicals to join the secretariat, I could feel their tremendous enthusiasm. We also have a sense of urgency to address the 2024 problem and anticipation regarding the meaningful collaboration of diverse members in this working group, which includes not only chemical manufacturers but also government agencies, logistics firms, and universities. Given this mix, Toray decided to join. Now, more than six months later, we have had the opportunity to discuss the 2024 problem from many different angles, and we have gained many insights. We've also been able to reference the latest information while considering individual challenges, which reminds me of the significance of our participation.

Yorita, Mitsui Chemicals:Indeed, I believe it's important to thoroughly discuss the issues from diverse perspectives. The working group includes not only chemical manufacturers such as us, but also, as Mr. Yuri mentioned, major logistics firms. It's quite significant that we can bring together diverse thinking on issues, ideas for solutions, as well as resources.

Hayashi, Mitsubishi Chemical Group:At the start in July 2023, we had about 40 companies participating in the working group. By the end of the year, that number had increased to around 70. It's noteworthy that the leading role is played by private-sector companies, and such a large participation from various companies is unprecedented in other industries. The people from the Ministry of Economy, Trade, and Industry were very surprised about this.

Oshima, Mitsubishi Chemical Group:I think the realization of cross-industry collaboration is possible because we have a sense of urgency and common recognition of the 2024 problem, and also because we've been able to gain support for our vision of not only cost-efficiency but also sustainable logistics. I believe the collective effort across the chemicals industry will create significant synergies and lead to substantial developments.

In order to tackle the 2024 problem, over 70 companies in the chemicals industry have recognized the necessity for collaboration and shifted from individual efforts to joint logistics through the Chemicals Working Group. In Part 2, we will hear about the concrete action and direction being taken with joint logistics. This discussion will provide insights into the envisioned future of joint logistics initiatives across the entire chemicals industry.

- *1 Physical internet: A concept for companies and industries to share information with each other on logistics resources through efforts such as the standardization of interfaces. The purpose is to streamline distribution, such as through the optimization of storage and transportation routes.

- *2 Sustainable Logistics Declaration: A campaign to boost truck transportation productivity and distribution efficiency, as well as to create better working environments that are welcoming to drivers who are female or age 60 and up. The declaration was issued in response to an increasingly severe shortage of truck drivers. The ultimate aim is to ensure the stable distribution that citizens' lives and industrial activity require, as well as to contribute to economic growth.