Environmental Conservation

Mitsubishi Chemical Corporation

Basic Policy and Key Measures

Aiming to contribute to the global environment, Mitsubishi Chemical (MCC) proactively works to reduce its greenhouse gas emissions, conserve resources and energy, prevent contamination of the air, water and soil, limit waste generation, encourage reuse and recycling, engage in activities and develop technologies that help conserve the natural environment, and develop and produce environmentally friendly products. In these ways, MCC strives to reduce its environmental burden at every level of its business activities.

In addition, to ensure legal compliance, we carry out training on environmental laws and regulations, conduct environmental audits and hold twice annual liaison meetings at which MCC Group managers in charge of environmental issues exchange the latest information about legal amendments and other issues.

In fiscal 2020, we set the annual targets of zero environmental incidents and contributing to the global environment and implemented the following key measures.

- ■ Reducing Environmental Risk

- We are implementing legal education and environmental audits to ensure compliance with environmental laws and regulations while systematically reducing environmental risk by implementing risk assessments.

- ■ Reducing Environmental Impact

- We are working to reduce our environmental impact through such means as cutting greenhouse gas emissions, saving resources and energy, and reducing emissions of pollutants.

- ■ Coexisting Harmoniously with Local Communities

- We are letting local communities know about our environmental conservation initiatives and promoting harmonious coexistence through communication.

Addressing Climate Change

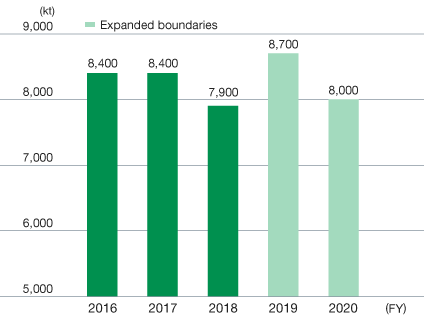

In line with the target set by Mitsubishi Chemical Group Corporation of reducing greenhouse gas emissions at least 17% compared with fiscal 2005 levels by fiscal 2015, MCC worked to cut its greenhouse gas emissions and achieved the fiscal 2015 target. We have maintained emissions at this lower level since fiscal 2016.

Going forward, we will advance initiatives to further reduce greenhouse gas emissions in line with the MCC Group medium-term management plan, which includes initiatives aimed at helping achieve the Japanese government’s emissions reduction targets for 2030.

- *Data for fiscal 2016 are the totals of the figures for the previous Mitsubishi Chemical, Mitsubishi Plastics, Mitsubishi Rayon, and their respective domestic group companies.

- **GHG emissions have been calculated based on the GHG Protocol.

- ***Figures for fiscal 2019 and after have been revised in line with the expansion of the boundaries of Mitsubishi Chemical Group Corporation’s medium- to long-term basic management strategy, KAITEKI Vision 30.

Focus: Reducing GHG Emissions Using Biomass Fuel at the Hiroshima Plant

The on-site power generation facilities of MCC’s Hiroshima Plant use coal-fired boilers to produce and supply electricity and steam. These boilers previously represented approximately 90% of the plant’s CO2 emissions. To reduce this significant environment burden, since 2008, we have been studying the use of fuels that help reduce CO2 emissions. Through the full-scale use of co-firing with biomass fuel, including wood scraps, in fiscal 2019 we achieved an annual CO2 reduction effect of 4,700 tons. Going forward, we aim to further increase the co-firing rate and thereby enhance the CO2 reduction effect.

Balancing CO2 emission reduction with fuel cost, we will continue to work as one to realize KAITEKI using environmentally friendly technologies.

Life Cycle Assessment

Life cycle assessment is an approach that enables the quantitative evaluation of the environmental burden generated by a product or service over its entire life cycle (from resource collection through raw material production, product manufacturing, distribution, consumption, disposal and recycling) or at specific stages of said life cycle. The evaluation of the environmental impact of MCC’s products and services over their entire life cycles better enables the company to develop environmentally friendly products and services and provide them to society.

Preventing Air, Water and Soil Pollution

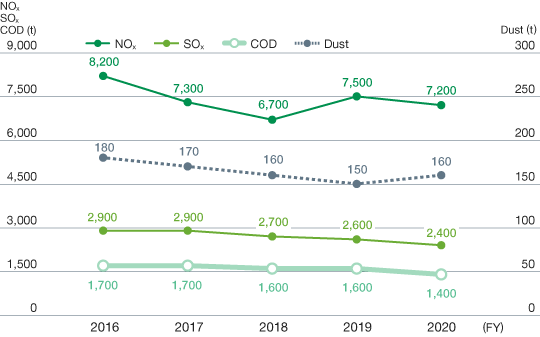

MCC handles a wide range of chemical substances and therefore maintains ongoing measures to reduce emissions of hazardous air pollutants and of pollutants into public bodies of water through such means as installing and improving emission gas and wastewater treatment facilities.

We have been reducing or maintaining at a steady level the environmental burden our businesses place on atmospheric and water quality, as measured by NOX, SOX and dust emissions as well as chemical oxygen demand (COD). MCC’s emissions of PRTR-regulated substances*1 and VOCs*2 have also been declining.

- *1Pollutant Release and Transfer Register (PRTR):

A system for filing notifications of the amounts of chemical substances released and transferred. This system enables the identification, aggregation and publishing of data on the types, sources and amounts of hazardous chemical substances that have been released into the environment or transferred outside facilities as waste. - *2Volatile organic compound (VOC):

Typical substances include toluene and xylene. These compounds became subject to regulation by the amended Air Pollution Control Act of 2006 as source substances of photochemical oxidants (photochemical smog). - ※Figures for fiscal 2019 and after have been revised in line with the expansion of the boundaries of Mitsubishi Chemical Group Corporation’s medium- to long-term basic management strategy, KAITEKI Vision 30.

Focus: Environmental Conservation Initiatives at the Shiga Plant

MCC’s Shiga Plant uses a great volume of plastic pellets as raw materials. The plant takes steps to prevent these pellets from spilling into public waterways, such as setting up pellet-catching nets in rainwater drainage channels.

In addition, every year, the Shiga Plant takes part in a day of mass-cleanup activities around Lake Biwa and Lake Yogo coordinated by Nagahama City and a Nagahama beautification group, working to conserve the environment in the local area. We will continue to implement initiatives to protect the environment and the area’s natural beauty.

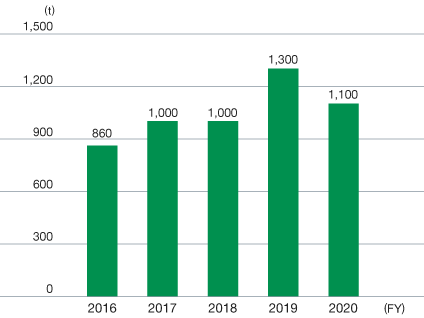

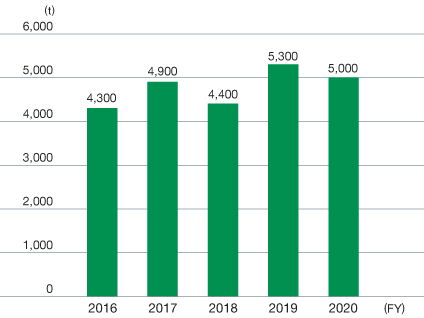

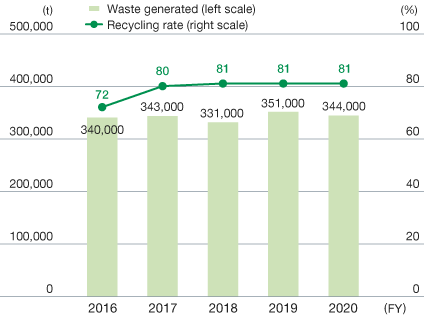

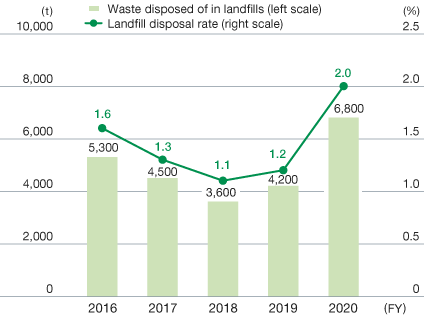

Waste Reduction and Recycling

MCC is advancing 3R activities (reduce, reuse, recycle) in an effort to reduce its waste. The waste recycling rate has been increasing, and the amount of waste disposed of in landfills has been decreasing, but in fiscal 2020, plant demolition generated one-off waste that resulted in an increase in waste disposed of in landfills. Going forward, we will continue working to improve our waste recycling rate by strictly enforcing sorted collection and strengthening coordination with disposal contractors.

- ※Figures for fiscal 2019 and after have been revised in line with the expansion of the boundaries of Mitsubishi Chemical Group Corporation’s medium- to long-term basic management strategy, KAITEKI Vision 30.

Biodiversity Conservation

Based on the

Mitsubishi Chemical Group Biodiversity Preservation Policy

, MCC pursues initiatives that contribute to the global environment and thus conserve biodiversity. Through these initiatives, we work to reduce environmental risk and impact and thereby lessen our business activities’ impact on biodiversity. In addition, we strive to conserve the natural environment by cleaning up neighboring areas and coastal areas and protecting our plants’ green areas.

Environmental Accounting

MCC uses environmental accounting, based on the Ministry of the Environment’s guidelines, to better understand the costs and effects of its environmental burden reduction and conservation efforts.

In fiscal 2020, MCC invested ¥2.2 billion in such areas as reinforcing wastewater management and air pollution prevention and incurred ¥35.1 billion in expenses, including those for the operation and maintenance of pollution prevention equipment and proper waste disposal. Meanwhile, such positive factors as revenue from the sale of valuable materials and savings from energy use and lower waste disposal costs totaled ¥1.2 billion.

Investment and Expenses Related to Environmental Conservation and Process Safety

Environmental conservation costs

(Millions of yen)

| Category | Main initiatives | FY2020 | ||

|---|---|---|---|---|

| Investment | Expenses | |||

| Costs within business areas | Pollution prevention costs | Air pollution prevention, dust countermeasure reinforcement, dust collection system replacement, water pollution prevention, activated sludge consolidation, wastewater management reinforcement, response to deterioration of wastewater facilities and pipes, etc. | 1,639 | 15,642 |

| Global environmental conservation costs | CO2 emissions reduction, operational improvement, etc. | 313 | 902 | |

| Resource-recycling costs | Industrial waste reduction, proper waste disposal, resource conservation, energy conservation, etc. | 241 | 7,851 | |

| Upstream/downstream costs | Waste reclamation, green purchasing, etc. | 0 | 0 | |

| Environmental conservation costs in management activities | Operation of units to address environmental conservation, ISO 14001 compliance and renewal, national exams, environmental education, etc. | 0 | 2,123 | |

| Environmental conservation costs in R&D activities | R&D for increased productivity | 0 | 7,418 | |

| Environmental conservation costs in social contribution activities | Construction and upkeep of factory green spaces | 17 | 489 | |

| Costs of dealing with environmental damage | Cleanup of contaminated soil, etc. | 2 | 72 | |

| Other environmental conservation-related costs | 0 | 570 | ||

| Total | 2,212 | 35,067 | ||

Positive economic effects(Millions of yen)

| FY2020 | |

|---|---|

| Income from recycling | 698 |

| Energy cost savings | 277 |

| Income from resource conservation | 193 |

| Total | 1,168 |