Components with Compliant Mechanism Design Adopted for Lunar Rover YAOKI

April 12, 2024

The Mitsubishi Chemical Group (hereinafter the "MCG Group") is pleased to announce that its resin components with compliant mechanism design have been adopted for the YAOKI lunar rover. YAOKI is a lunar rover being developed by Dymon Co., Ltd. (Headquarters: Ota-ku, Tokyo; President: Shinichiro Nakajima; hereinafter "Dymon"), a robotics and space development startup, with the aim of becoming the world’s first private company to conduct lunar exploration by the end of 2024.

Compliant mechanism is a design concept that allows a product to be molded in one-piece from an elastic material, allowing it to flexibly transmit force and motion to achieve its intended function. In contrast to conventional molded products where movement is achieved by assembling rigid parts and movable parts such as screws and springs, this method allows designers to design components with features such as improved operational accuracy, fewer parts, maintenance-free operation, quieter operation, and improved recyclability from the use of mono-material materials. The MCG Group is promoting product development that utilizes compliant mechanisms as a new approach that marries its knowledge of materials—the Group’s strength as a general chemical manufacturer—with structural design and optimization simulation technology.

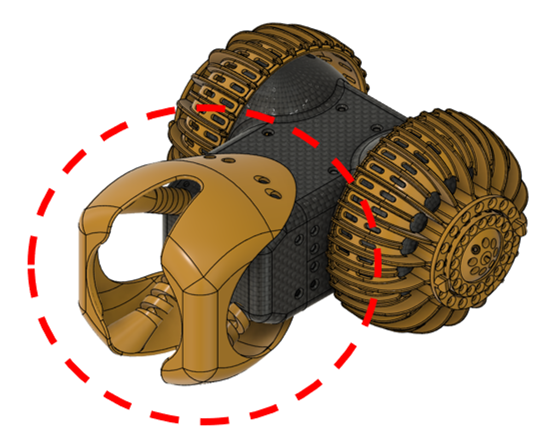

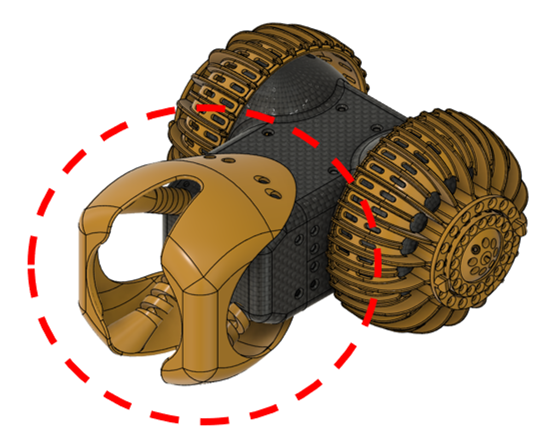

The MCG Group and Dymon have signed a partnership agreement under which the Group provides carbon fiber reinforced plastic components and technical support for the development of YAOKI. One of the required functions of components designed for this project is to stabilize the vehicle body while it is in motion, and be able to resist impact shocks that can occur during falls. The challenge, however, was that a highly rigid design that would lead to increased weight would not be tenable due to the cost of transportation. To address this issue, by incorporating the compliant mechanism concept in our design and reviewing the structures of these components from the materials up, we succeeded in designing a model with significantly better shock resistance compared to conventional products while minimizing increases in weight. We have used the FIM* (Freeform Injection Molding) technology of our group company, MCC Advanced Moldings Co.,Ltd. to injection-mold complex shapes that are impossible to form by ordinary injection molding into one piece using super engineering plastic.

Going forward, the MCG Group will continue to promote compliant mechanism product development by combining its strengths in materials knowledge and molding technologies, with the aim of providing value not only for space applications but also in a wide range of other fields.

* A molding method where a mold is created using a stereolithography 3D printer, resin is injected into the mold, and the mold is then dissolved and removed to obtain the product.

Compliant mechanism is a design concept that allows a product to be molded in one-piece from an elastic material, allowing it to flexibly transmit force and motion to achieve its intended function. In contrast to conventional molded products where movement is achieved by assembling rigid parts and movable parts such as screws and springs, this method allows designers to design components with features such as improved operational accuracy, fewer parts, maintenance-free operation, quieter operation, and improved recyclability from the use of mono-material materials. The MCG Group is promoting product development that utilizes compliant mechanisms as a new approach that marries its knowledge of materials—the Group’s strength as a general chemical manufacturer—with structural design and optimization simulation technology.

The MCG Group and Dymon have signed a partnership agreement under which the Group provides carbon fiber reinforced plastic components and technical support for the development of YAOKI. One of the required functions of components designed for this project is to stabilize the vehicle body while it is in motion, and be able to resist impact shocks that can occur during falls. The challenge, however, was that a highly rigid design that would lead to increased weight would not be tenable due to the cost of transportation. To address this issue, by incorporating the compliant mechanism concept in our design and reviewing the structures of these components from the materials up, we succeeded in designing a model with significantly better shock resistance compared to conventional products while minimizing increases in weight. We have used the FIM* (Freeform Injection Molding) technology of our group company, MCC Advanced Moldings Co.,Ltd. to injection-mold complex shapes that are impossible to form by ordinary injection molding into one piece using super engineering plastic.

Going forward, the MCG Group will continue to promote compliant mechanism product development by combining its strengths in materials knowledge and molding technologies, with the aim of providing value not only for space applications but also in a wide range of other fields.

* A molding method where a mold is created using a stereolithography 3D printer, resin is injected into the mold, and the mold is then dissolved and removed to obtain the product.