Mitsubishi Chemical Group to Commence Full-fledged Verification Testing for the World’s First Commercialization of Polycarbonate Resin Chemical Recycling

Conducting testing for collecting polycarbonate resin from headlamps of end-of-life vehicles in collaboration with Tokio Marine & Nichido and ABT

January 26, 2024

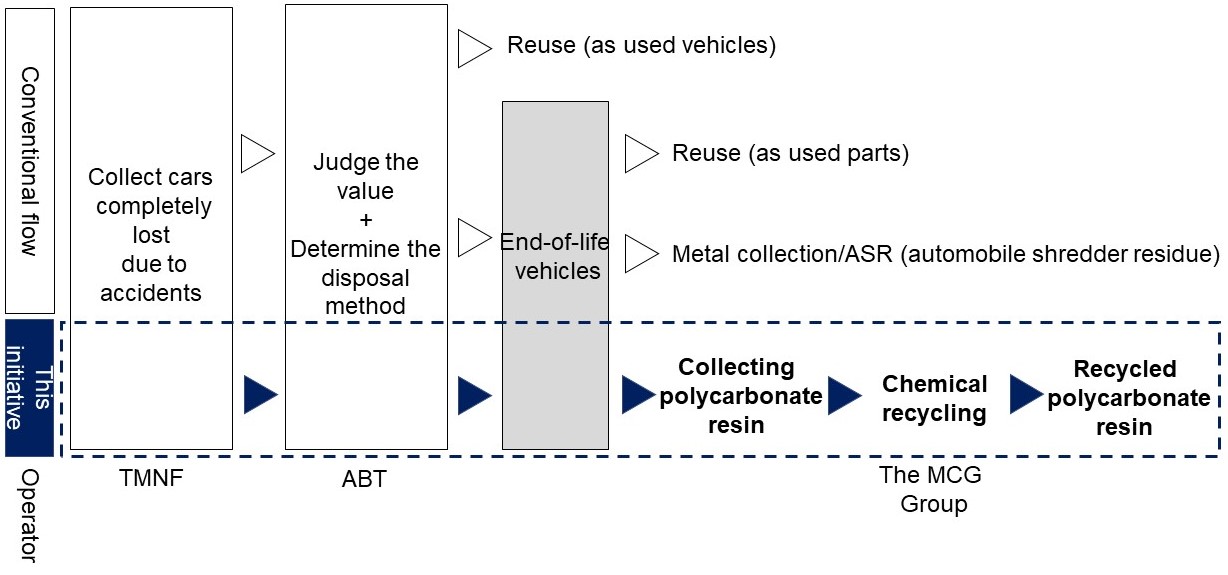

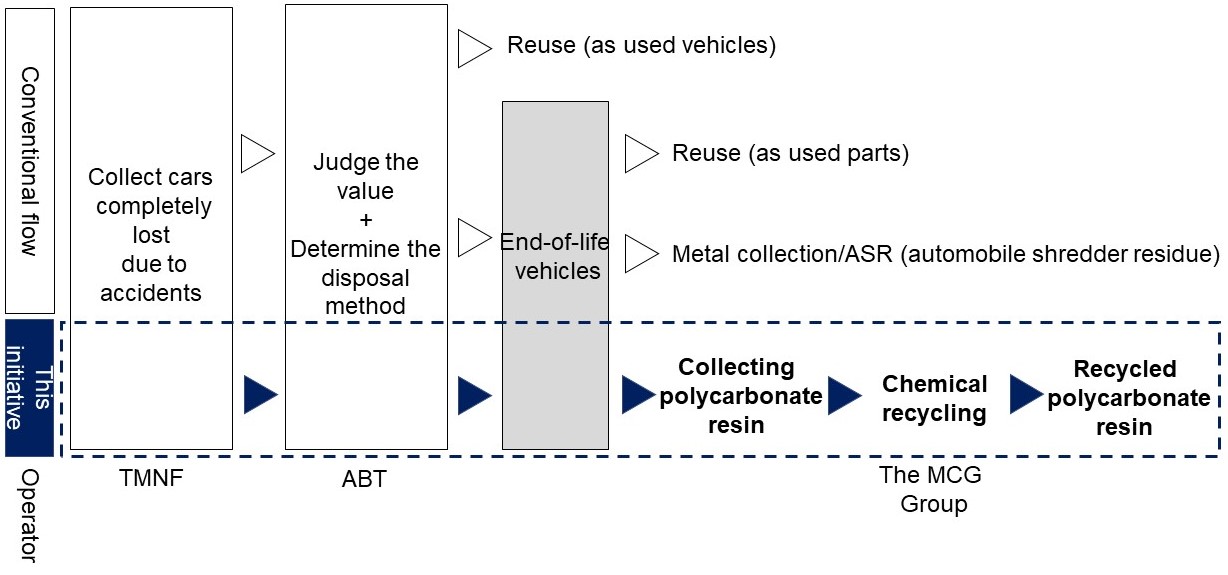

The Mitsubishi Chemical Group (MCG Group) will start verification testing of a scheme for collecting polycarbonate (PC) resin from headlamps of end-of-life vehicles in the Kanto region in January 2024 with a view to the world’s first commercialization of PC resin chemical recycling. The testing will be conducted in collaboration with Tokio Marine & Nichido Fire Insurance Co., Ltd. (TMNF; Head office: Chiyoda-ku, Tokyo; President: Shinichi Hirose) and ABT Corporation*1 (ABT; Head office: Chiyoda-ku, Tokyo; President: Tadashi Fujimoto).

1. MCG Group’s test bench facility for PC resin chemical recycling

The MCG Group completed the construction of a test bench facility for demonstrating PC resin chemical recycling at Mitsubishi Chemical Corporation’s Kyushu Plant in Kitakyushu City, Fukuoka Prefecture, in September 2023 and started in the following month a demonstration to recycle used PC resin collected from the market.

This demonstration project has been adopted as a subsidized project for the Ministry of the Environment’s “FY2022 Demonstration Project for a Plastic Resource Circulation System toward a Decarbonized Society” program.

The MCG Group aims not only to establish chemical recycling technology for producing high-quality recycled PC resin but to build a recycling system for used PC resin. Toward this end, the Group is currently collaborating with companies that use PC resin for their products and exploring ways to recover used PC resin from various end-of-life products, with the goal of achieving the social implementation of a PC resin recycling system.

Headlamps collected from end-of-life vehicles

Chemical recycling test bench facility completed (Mitsubishi Chemical Corporation’s Kyushu Plant)

2. Verification testing to be conducted from January 2024

The MCG Group, TMNF, and ABT have been working together since February 2023 to verify the processes of recovering acrylic resin from automotive tail lamps, etc. by—as the first attempt in Japan—making use of TMNF’s and ABT’s network for the processing and disposal of end-of-life vehicles.

From January 2024, the MCG Group and its partners will start another verification testing in the Kanto region, this time for automotive headlamps, which are more difficult to recover than tail lamps. Based on the verification results obtained from the testing, such as those regarding operations, material quality, and costs, the Group will gradually expand locations in which verification testing is conducted throughout Japan.

While continuing to supply high-value-added specialty products and collaborating with many partners, the MCG Group will also commit itself to developing a recycling system for such products to contribute to the realization of a sustainable society.

*1: ABT Corporation is a wholly owned subsidiary of Central Automotive Products Ltd. (Head office: Kita-ku, Osaka; President: Shinichiro Sakata).

Reference

- Press release dated March 15, 2023 “Study on the World's First Commercialization of Polycarbonate Resin Chemical Recycling”

https://www.mcgc.com/english/news_release/01528.html

- Press release from the Ministry of the Environment dated August 5, 2022 “MOE Japan Selects Entrusted and Subsidized Projects for the "FY2022 Demonstration Project for a Plastic Resource Circulation System toward a Decarbonized Society" Program (First Round)”

https://www.env.go.jp/en/press/press_00350.html

- Press release dated February 20, 2023 “Establishment of Japan’s First Acrylic Resin Collection Scheme in Collaboration with Tokio Marine & Nichido and ABT—Verification testing for the commercialization of molecular recycling will begin—

https://www.mcgc.com/english/news_release/01501.html

1. MCG Group’s test bench facility for PC resin chemical recycling

The MCG Group completed the construction of a test bench facility for demonstrating PC resin chemical recycling at Mitsubishi Chemical Corporation’s Kyushu Plant in Kitakyushu City, Fukuoka Prefecture, in September 2023 and started in the following month a demonstration to recycle used PC resin collected from the market.

This demonstration project has been adopted as a subsidized project for the Ministry of the Environment’s “FY2022 Demonstration Project for a Plastic Resource Circulation System toward a Decarbonized Society” program.

The MCG Group aims not only to establish chemical recycling technology for producing high-quality recycled PC resin but to build a recycling system for used PC resin. Toward this end, the Group is currently collaborating with companies that use PC resin for their products and exploring ways to recover used PC resin from various end-of-life products, with the goal of achieving the social implementation of a PC resin recycling system.

Headlamps collected from end-of-life vehicles

Chemical recycling test bench facility completed (Mitsubishi Chemical Corporation’s Kyushu Plant)

2. Verification testing to be conducted from January 2024

The MCG Group, TMNF, and ABT have been working together since February 2023 to verify the processes of recovering acrylic resin from automotive tail lamps, etc. by—as the first attempt in Japan—making use of TMNF’s and ABT’s network for the processing and disposal of end-of-life vehicles.

From January 2024, the MCG Group and its partners will start another verification testing in the Kanto region, this time for automotive headlamps, which are more difficult to recover than tail lamps. Based on the verification results obtained from the testing, such as those regarding operations, material quality, and costs, the Group will gradually expand locations in which verification testing is conducted throughout Japan.

While continuing to supply high-value-added specialty products and collaborating with many partners, the MCG Group will also commit itself to developing a recycling system for such products to contribute to the realization of a sustainable society.

*1: ABT Corporation is a wholly owned subsidiary of Central Automotive Products Ltd. (Head office: Kita-ku, Osaka; President: Shinichiro Sakata).

Reference

- Press release dated March 15, 2023 “Study on the World's First Commercialization of Polycarbonate Resin Chemical Recycling”

https://www.mcgc.com/english/news_release/01528.html

- Press release from the Ministry of the Environment dated August 5, 2022 “MOE Japan Selects Entrusted and Subsidized Projects for the "FY2022 Demonstration Project for a Plastic Resource Circulation System toward a Decarbonized Society" Program (First Round)”

https://www.env.go.jp/en/press/press_00350.html

- Press release dated February 20, 2023 “Establishment of Japan’s First Acrylic Resin Collection Scheme in Collaboration with Tokio Marine & Nichido and ABT—Verification testing for the commercialization of molecular recycling will begin—

https://www.mcgc.com/english/news_release/01501.html