Products

Thermoplastic Carbon Fiber Prepreg (Kyron™ULTRA)

※This is a product in the development stage.

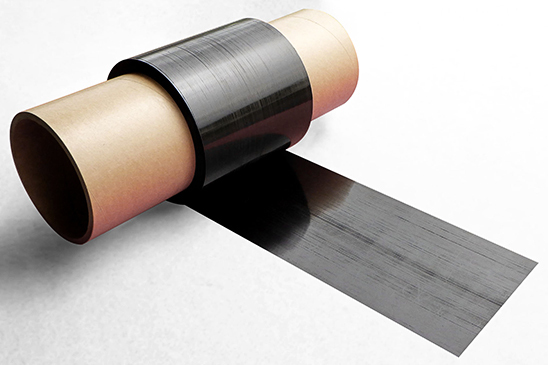

Kyron™ULTRA is a new sheet-like intermediate material

developed by Mitsubishi Chemical, in which carbon fibers are

impregnated with engineering plastics. It is a high performing

carbon fiber composite material in the form of a UD

(Uni-Directional) prepreg with carbon fiber in one

direction.

▶Click here for Thermoset Carbon Fiber Prepregs.

In-page menu

Features

Kyron™ULTRA, which is benefited from Mitsubishi Chemical's expertise in carbon fiber technology, resin engineering, and composite material design, offers the following characteristics:

Performance

A prepreg that makes the most of the characteristics of carbon fiber and thermoplastic resin with our composite material technology.

High quality

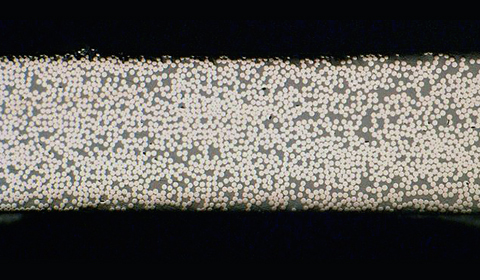

Kyron™ULTRA features ultra-low voids and high dimensional accuracy, making it applicable for thermoplastic ATL (Auto Tape Layup) molding technology, general-purpose stamping technology, etc.

High formability

With ultra-low voids, takt time (process work time) can be shortened in general-purpose stamping. In addition, freezer storage of materials is not required.

This image demonstrates that the internal void is kept to a minimum.

Applications

Making the most of the anisotropic nature of carbon fiber,

UD prepreg can greatly expand the range of product design by

placing the necessary prepreg in the right place.

Harnessing the characteristics of both carbon fiber and

thermoplastic resin, it can be used in a wide range of

fields such as aerospace, industry, mobility, and

snowboards.

Product Lineup

UD Prepreg (Uni-directional Prepreg)

Kyron™ULTRA Development Products

| Product name | Carbon fiber type | Matrix resin | Fiber Volume Fraction (%) |

FAW (g/m2) |

Thickness (mm) |

0°Tensile Strength* (MPa) |

0°Tensile Modulus* (GPa) |

90°Flexural Strength* (MPa) |

Dry Tg (DMA / ℃) |

Thermal conductivity (@150℃) In-plane fiber orientation (W/(m·K)) |

Thermal conductivity (@150℃) Thickness direction (W/(m·K)) |

Processing temperature (℃) | Remarks |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| TR K71F145SH TR K71F190SH |

PAN-Standard Modulus | Oil resistance Poly Ether Imido (PEI) |

60 | 145 190 |

0.135 0.180 |

2360 | 129 | 86 | 225 | <10 | <1 | 320~360 | Advanced Chemical Resistant |

| TR K72F145SH TR K72F190SH |

PAN-Standard Modulus |

Advanced Moldability Poly Ether Imido (PEI) |

60 | 145 190 |

0.135 0.180 |

2350 | 134 | 80 | 215 | <10 | <1 | 280~320 | Advanced Moldability |

| USPK72W150SH | Pitch-High Modulus |

Advanced Moldability Poly Ether Imido (PEI) |

60 | 145 190 |

0.12 | 1670 | 380 | 49 | 215 | 100 | 1.3 | 280~320 | Advanced Moldability |

| TR K42F145SH TR K42F190SH |

PAN-Standard Modulus | Poly Ether Ether Keton (PEEK) |

60 | 145 190 |

0.135 0.180 |

1980 | 131 | 124 | 145 | <10 | <1 | 380~400 | - |

| MR K42F145SH MR K42F190SH |

PAN-Intermediate Modulus | Poly Ether Ether Keton (PEEK) |

60 | 145 190 |

0.135 0.180 |

2490 | 155 | 142 | 145 | <10 | <1 | 380~400 | - |

*Full Consolidate Thickness (FCT) of test pieces are 2.05 -

2.08 mm.

※The values in the table are representative

values and not guaranteed.