Products

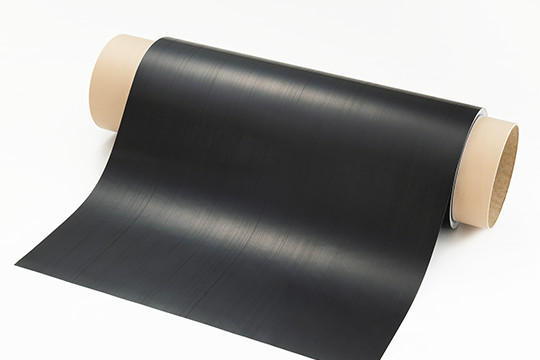

Thermoset Carbon Fiber Prepreg

Thermoset Carbon Fiber Prepreg is an intermediate material in

the form of a sheet of carbon fiber impregnated with thermoset matrix resin. There are various types of

prepreg such as UD prepreg (unidirectional prepreg), in which carbon

fibers are aligned in one direction, and cloth prepreg, in which carbon fibers are woven into a fabric

and impregnated with matrix resin.

▶ Please see this page about thermoplastic carbon fiber

prepreg.

In-page menu

Features

Mitsubishi Chemical offers a wide range of prepreg products, including UD prepreg, cloth prepreg, and special prepreg.

For prepreg consisting of carbon fiber and thermoset

matrix resin, it is necessary to select the most suitable carbon fiber and resin for the particular

application.

Mitsubishi Chemical has developed various of its own thermoset matrix resin to meet

the needs of different application, enabling it to offer prepregs of various characteristics, such

as rapid curing, heat resistance, and high toughness.

Applications

UD prepreg takes advantage of the anisotropic nature

of carbon fiber to greatly expand the range of product design, by placing the necessary prepreg in the

right place at the right time.

Cloth prepreg offers excellent drape property, making it well

suited to creating shapes that follow the contours of product. Due to its good “designability,” it is

also very well suited for exterior applications.

Product Lineup

- Prepreg is available in unidirectional (UD) —with carbon fibers aligned in a single direction—and woven fabric (cloth) formats.

- By selecting the fiber type and fiber areal weight (FAW), together with the resin system and resin content, we supply products tailored to your specifications.

- For representative products, please refer to our catalog.

Matrix Resin List

Epoxy Type

| Resin Code | Curing Temp(℃) | Tg(℃) | Feature | Main Application※ |

|---|---|---|---|---|

| #350 | 130 | 120 | Multi purpose High toughness |

|

| #349 | 130 | 120 | Multi Purpose without addition of haloge High toughness |

|

| #381 | 130 | 120 | Transparent appearance Suitable for exterior application as fabric prepreg |

|

| #302 | 130 | 120 | High impact resistance |

|

| #333 | 130 | 120 | Multi purpose suitable for Pitch-based CF Used for industrial and satellite application |

|

| #392 | 130 | 130 | Rapid curing High rigidity |

|

| #393 | 130 | 120 | Rapid curing Suitable for inner pressure molding |

|

| #395 | 130 | 130 | Rapid curing High toughness |

|

| #362 | 130 - 140 | 170 | Suitable for press molding (PCM method) Excellent surface quality |

|

| #3R2 | 130 - 150 | 170 | Suitable for press molding (PCM method) De-molding at 170℃ possible. |

|

| #367 | 130 - 140 | 140 | Rapid curing High rigidity |

|

| Xlink tech | 130 | 120 | High toughness & High rigidity High properties with high-modulus CF |

|

| #400 series | 130 | 130 - 170 | Made from bio-derived raw materials Segregation method |

|

| #500 series | 130 | 130 - 170 | Made from bio-derived raw materials Mass Balance method (ISCCPLUS) |

|

| #830 | 80 | 80 | 80°C curing Suitable for large object production by oven curing. |

|

| #853 | 80 (Demolding) 180 (Post-curing) |

180 | High Tg after post cure, Low Coefficient of Thermal

Expansion Suitable for industrial and aerospace tools |

|

| #600 | 130 | 130 | Flame retardant, Rapid curing Non halogen and less heavy metal |

|

| HX1(#221) | 180 | 150 | Multi purpose suitable for Pitch-based CF Used for industrial and satellite application |

|

| #261 | 180 | 160 | Heat resistance, transparent appearance Used for industrial and automotive application |

|

| #270 | 180 | 180 | Heat resistance, high toughness and low Coefficient of

Thermal Expansion Suitable for aerospace tools |

|

| #266 | 180 | 180 | Heat resistance, high toughness Multi industrial applications |

|

| #108 | 180 | 160 | Heat resistance, high toughness Aerospace applications |

|

Special Type

| Resin Code | Curing Temp(℃) | Tg(℃) | Feature | Main Application※ |

|---|---|---|---|---|

| #290 | 135 (Demolding) 250 (Post-curing) |

270 | Cyanate ester resin Heat resistant, high toughness and low water absorption 180°C curing without post-curing also possible. |

|

:

Aerospace

:

Aerospace

:

Automotive

:

Automotive

:

Space

:

Space

:

Sports

:

Sports

:

Industrial

:

Industrial

Standard product specifications

- Width : UD prepreg 1,000mm, Woven fabric prepreg 1,000mm or 1,270mm

- Length : UD prepreg 125m, Woven fabric prepreg 50m.