High-Molecular weight saturated polyester resin

Nichigo-POLYESTER™

Feel free to contact us for technical inquires and ordering or to request catalogs, pricing estimates, etc.

- SPR Dept.

These are links for moving within this page

Crystalline polyester resins possessing a high level of structural cohesion, and which are resistant to dissolution in organic solvents. These resins display excellent adhesion with base materials including polyester films, vinyl chloride resins, metals, and fibers. They are ideal for use as hot-melt adhesives and hot-melt extrusion coatings.

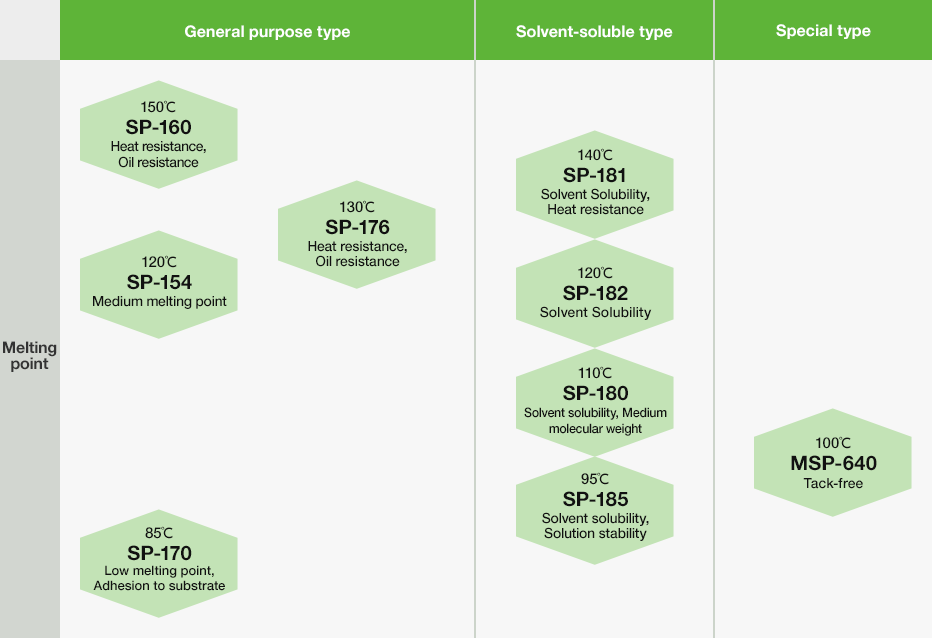

SP-154

Medium Melting point standard type. Mainly used as an additive for adhesive or a raw material for molding

SP-160

Highest melting point type, offering excellent heat resistance and oil resistance. Mainly used as an adhesive.

SP-170

The lowest melting point type in this series. Mainly used as an adhesive.

SP-176

High melting point type, offering excellent heat resistance and oil resistance. Mainly used as an adhesive.

SP-180

Medium molecular weight solvent-soluble type. Mainly used as an adhesive.

SP-181

Solvent-solublle type, offering excellent heat resistance. Mainly used as an adhesive.

SP-182

Solvent-soluble type, mainly used as an adhesive.

SP-185

Solvent-soluble type, offering comparatively good solution stability. Mainly used as an adhesive.

MSP-640

Tack-free after coating and drying, and able to wound. Mainly used as an adhesive for various films.

| Grade | Form | Molecular weight | Melt viscosity (Pa・s/190℃) |

Tg (℃) |

Melting point (℃) |

Flow start point (℃) |

Hardness (Shore D) |

Hydroxyl Value (mgKOH/g) |

Acid Value (mgKOH/g) |

Tensile strength (N/mm2) |

Tensile elongation (%) |

SP-154 | Pellet | 19000 | 150 | -20 | 120 | 132 | 57 | <5 | <2 | 23 | 900 | Medium melting point, standard type |

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SP-160 | Pellet | 19000 | 100 | -20 | 150 | 157 | 43 | 3~7 | <4 | 17 | 580 | High melting point, heat resistance, oil resistance |

|||||||||||||

| SP-170 | Pellet | 19000 | 200 | -20 | 85 | 98 | 38 | 3~7 | <2 | 10 | 950 | Low melting point, adhesion to base materials |

|||||||||||||

| SP-176 | Pellet | 22000 | 560 | 0 | 130 | 135 | 60 | 2~6 | <2 | 43 | 500 | High melting point, heat resistance, oil resistance |

|||||||||||||

| SP-180 | Pellet | 10000 | 130 (160℃) |

10 | 110 | 120 | 58 | 8~14 | <2 | 8 | 400 | Solvent solubility, medium molecular weight |

|||||||||||||

| SP-181 | Pellet | 22000 | 400 | 15 | 140 | 150 | 60 | 2~6 | <3 | 15 | 600 | Solvent solubility, heat resistance |

|||||||||||||

| SP-182 | Pellet | 22000 | 400 | 10 | 120 | 128 | 58 | 2~6 | <3 | 9 | 700 | Solvent solubility | |||||||||||||

| SP-185 | Pellet | 20000 | 100 | 5 | 95 | 110 | 57 | 2~7 | <3 | 8 | 800 | Solvent solubility, solution stability |

|||||||||||||

| MSP-640 | Solution | 10000 | 150 | 37 | 100 | 105 | 59 | 4~9 | <6 | 8 | 150 | Tack-free, solvent diluted |

High-Molecular weight saturated polyester resin

Nichigo-POLYESTER™

Feel free to contact us for technical inquires and ordering or to request catalogs, pricing estimates, etc.

This is the end of this page