UV Curable Urethane Acrylate Oligomer SHIKOH™

Feel free to contact us for technical inquires and ordering or to request catalogs, pricing estimates, etc.

- Coating Dept.

These are links for moving within this page

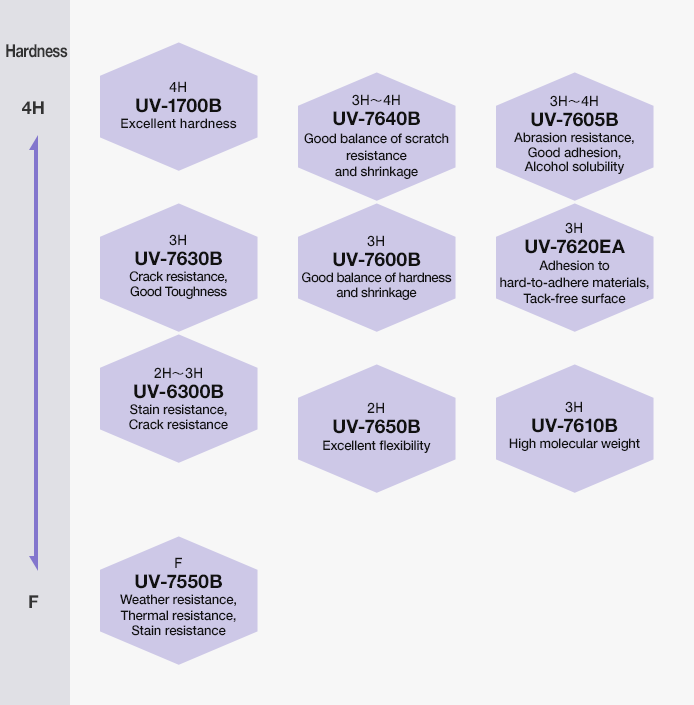

UV-1700B

Provides excellent UV curing performance and delivers the hardest surface of all product grades. Has relatively low viscosity.

UV-6300B

Creates a high-hardness coating ideal for hard coating applications. Provides greater stain and crack resistance compared to DPHA.

UV-7550B

Creates a hard coating with good weather resistance. Also provides excellent chemical, thermal, yellowing and stain resistance.

UV-7600B

Provides excellent adhesion and creates a high-hardness coating on treated PET and TAC films and other types of platic.

UV-7605B

Provides excellent adhesion and creates a high-hardness coating on various plastic materials. Its low viscosity provides excellent solubility in various solvents.

UV-7610B

Provides excellent adhesion and creates a high-hardness coating on various plastic materials.

UV-7620EA

Ideal for creating a high-hardness coating on hard-to-adhere materials. Provides a tack-free surface begore UV curing. Diluted in a solvent (contains 35% ethil acetate).

UV-7630B

Provides excellent adhesion and creates a high-hardness coating on various plastic materials. Also provides good crack resistance and good toughness.

UV-7640B

Provides excellent adhesion to various plastic materials. Also provides good curability, low shrinkage, high hardness, and excellent abrasion resistance.

UV-7650B

Provides good flexibility and excellent adhesion to plastic materials and treated PET and TAC films.

Diverse lineup with various characteristics such as good olefin adhesion and slight adhesion.

| Grade | Resin properties | Properties after UV curing | Characteristics & Applications | ||||||||

| Viscosity (mPa・s/60℃) |

Molecular weight (Mw) |

Oligomer functionality | Pencil hardness (PET) | Shrinkage ratio (%) | Adhesion to plastic* | ||||||

| PC | ABS | PMMA | Treated PET | TAC | |||||||

| UV-1700B | 1400~2000 | 2000 | 10 | 4H | 9.0 | ◎ | ◎ | ◎ | ◎ | ◎ | Excellent hardness Hard coating on plastic |

| UV-6300B | 2000~4000 | 3700 | 7 | 2H~3H | 7.3 | ◎ | ◎ | ○ | ◎ | ◎ | Stain resistance, Crack resistance Hard coating on optical films |

| UV-7550B | 10000~15000 | 2400 | 3 | F | 3.8 | △ | ○ | ○ | ◎ | △ | Weather resistance, Thermal resistance, Stain resistance Building materials |

| UV-7600B | 2000~4000 | 1400 | 6 | 3H | 6.3 | ◎ | ◎ | ○ | ◎ | ◎ | High hardness, Low shrinkage Hard coating on optical films |

| UV-7605B | 800~1400 | 1100 | 6 | 3H~4H | 7.7 | ◎ | ◎ | ○ | ◎ | ◎ | Abrasion resistance, Alcohol solubility Hard coating on optical films Hard coating on plastic |

| UV-7610B | 7000~27000 | 11000 | 9 | 3H | 8.4 | ◎ | ◎ | ○ | ◎ | ○ | High molecular weight Hard coating on metalizing materials Hard coating on plastic |

| UV-7620EA | 70~270(20℃) | 4100 | 9 | 3H | - | ◎ | ◎ | ○ | ◎ | ◎ | Adhesion to hard-to-adhere materials Tack-free surface Diluted in 35% ethyl acetate |

| UV-7630B | 3000~7000 | 2200 | 6 | 3H | 6.4 | ◎ | ◎ | ○ | ◎ | ○ | Crack resistance, Good toughness, Good balance of hardness and flexibility |

| UV-7640B | 2000~5000 | 1500 | 6~7 | 3H~4H | 6.6 | ◎ | ◎ | ○ | ◎ | ◎ | High hardness, Low shrinkage, Abrasion resistance Hard coating on optical films |

| UV-7650B | 3000~10000 | 2300 | 4~5 | 2H | 5.3 | ◎ | ◎ | ○ | ◎ | ◎ | Excellent flexibility Hard coating on plastic |

* ◎: Excellent adhesion ○: Good adhesion according to formulation △: Poor adhesion

UV Curable Urethane Acrylate Oligomer SHIKOH™

Feel free to contact us for technical inquires and ordering or to request catalogs, pricing estimates, etc.

This is the end of this page