Artificial Photosynthesis

A dream technology, converting CO₂ into a resource

Feb. 1, 2023 / TEXT BY YUYA OYAMADA / ILLUSTRAIONS BY SHINJI HAMANA

※ Article updated on Mar. 26, 2021

- Artificial Photosynthesis is a promising approach to reducing GHGs that uses CO₂ emitted from factories and power plants as a raw material for chemical products while using clean hydrogen produced from water by using solar energy.

As a member of the Japan Technological Research Association of Artificial Photosynthetic Chemical Process (ARPChem), which was established in October 2012, Mitsubishi Chemical Corporation (MCC) participated in an Artificial Photosynthesis project being conducted by New Energy and Industrial Technology Development Organization (NEDO) and has been pushing forward with joint development in partnership with domestic chemical manufacturers, universities, national institutes and other research institutions.

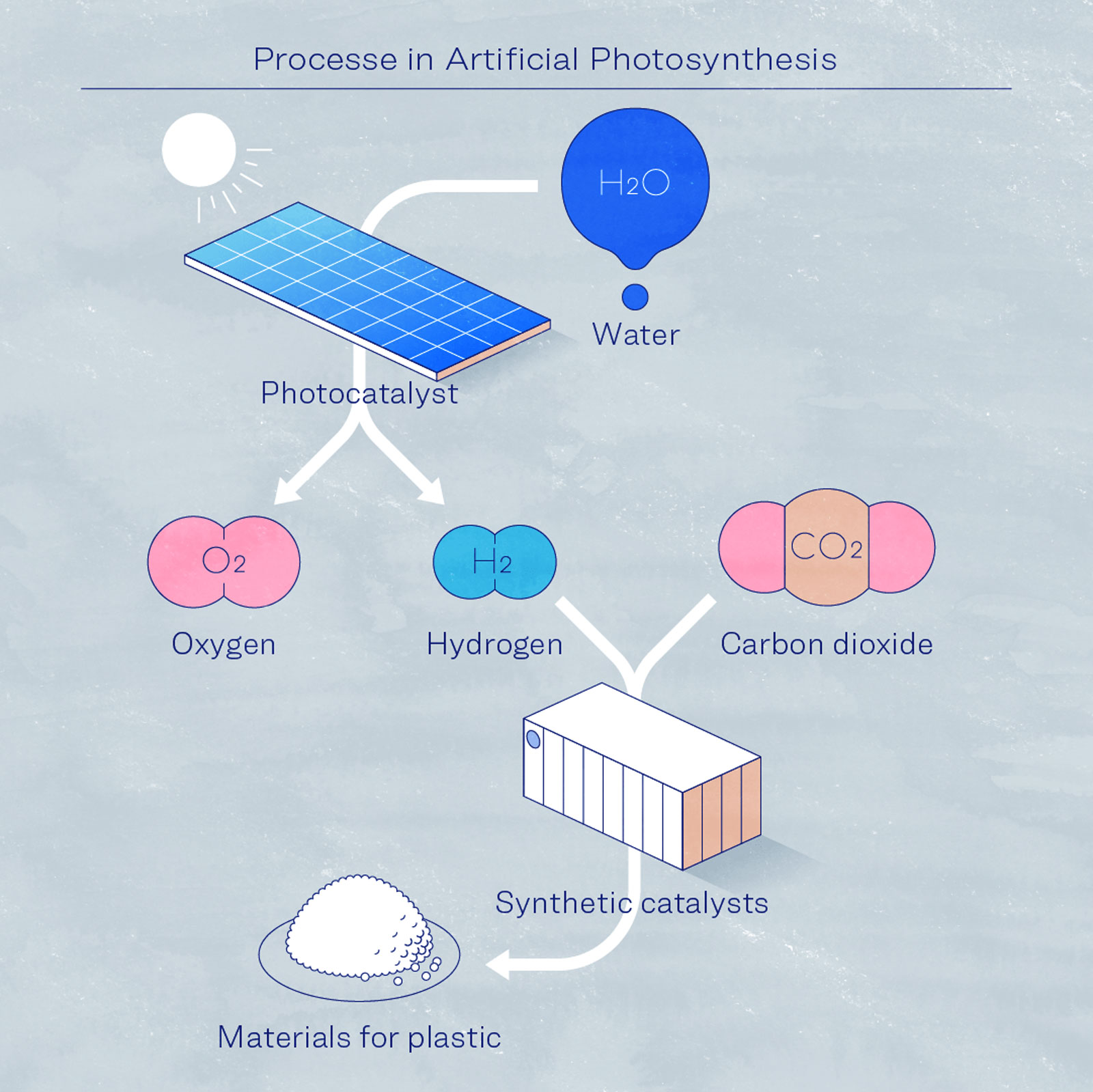

In Artificial Photosynthesis, solar energy is used to produce hydrogen from water. By using this hydrogen and the CO₂ emitted from factories and power plants to produce olefin, a large shift will be made to a CO₂ absorption process from chemical product production processes that previously emitted CO₂. MCC has been undertaking technological development for all of the three-step process for Artificial Photosynthesis.

Three processes in Artificial Photosynthesis

1. Splitting water into oxygen and hydrogen using sunlight and a photocatalyst

2. Using a separation membrane to split hydrogen from the emitted mixed gas, consisting of hydrogen and oxygen

3. Using catalyst to create a reaction between hydrogen and CO₂ to produce olefin

Splitting water into oxygen and hydrogen using sunlight and a photocatalyst

In the process of converting water into hydrogen and oxygen, the photocatalyst plays an important role. Light is shone on the catalyst, which is in sheet form and soaked in water, separates the water into hydrogen and oxygen without using electricity. A feature of this process is that, at the production stage, the process does not emit CO₂ as solar energy is used. In Artificial Photosynthesis, an important factor is the energy conversion efficiency rate, in other words how efficiently can energy conversion be carried out when producing hydrogen from solar energy. Research is in progress aimed at achieving an energy conversion efficiency rate of 4% by 2024 and 10% by 2030 using a photocatalytic sheet that can be produced in large size, which is expected to slash costs, and using the sheet to verify efficiency rates through outdoor testing at a testing site with an area of tens of thousands of square meters. Ahead of the implementation of Artificial Photosynthesis, the project’s photocatalyst is gaining attention as a technology that will lead the world.

Using a separation membrane to split hydrogen from the emitted mixed gas, consisting of hydrogen and oxygen

The hydrogen and oxygen gas mixture is explosive therefore it is immensely important to safely and efficiently separate the hydrogen and oxygen. In this project, in addition to the development of a high-performance separation membrane (for separating hydrogen from the mixed gas), the development of an extremely safe separation module is also underway.

Using catalyst to create a reaction between hydrogen and CO₂ to produce olefin

A synthetic catalyst is crucial to the production of olefin. This production is carried out by making the separated hydrogen react with CO₂. A catalyst and process technologies to realize high yields and high-level production were developed and proof-of-concept verification has already proven successful on a small- pilot scale. Olefin that is produced using this set of processes thereby becomes a raw material for producing plastic.

Commercial Development of Artificial Photosynthesis-based Chemical Raw Material Production was selected as a Green Innovation Fund Project by NEDO in February 2022. The Artificial Photosynthesis project was moved to the next stage for social implementation. To achieve carbon neutrality, MCC will convert raw materials from petroleum and drive development of plastic production technology using carbon dioxide by utilizing petrochemical manufacturing technology, catalyst development technology and other technologies it has cultivated while collaborating with universities and research institutes affiliated with other companies participating in the project.