A Hollow Fiber Membrane Ideally Suited for Water Treatment Solutions STERAPORE™

- Language

Outstanding Filtration Functions for Diverse Applications

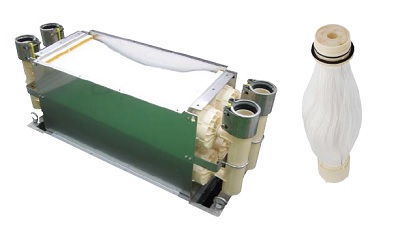

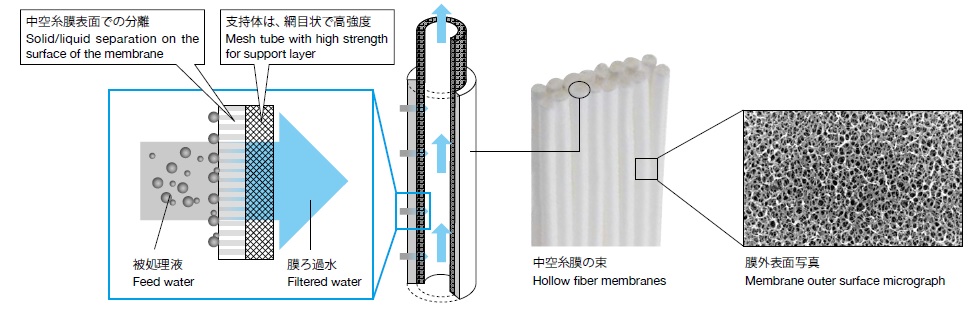

STERAPORE™ is an extremely thin, straw-shaped hollow fiber membrane. The countless number of micropores on the membrane’s surface serve to filter any liquid or air that passes through, efficiently removing fine particles and bacteria. With the ability to filter substances in excess of 0.1 μm, STERAPORE™ is widely used in home-use water filters, water purification and sewage/wastewater treatment systems, and even industrial separation, refining, and concentration equipment.

STERAPORE™ comes in two membrane types: a polyethylene (PE) membrane and a polyvinylidene fluoride (PVDF) membrane. The PE membrane was the first to be developed, and since it doesn’t contain any solvents or plasticizers, it is a clean option with low dissolution of impurities. As such, among other applications, it is used in water filters and pure water filters for medical and electronic material applications. Later, to cater to market needs, MCC(Mitsubishi Chemical Corporation) developed the PVDF membrane for use in wastewater treatment. With strong oxidation resistance, long service life, and high functionality, the PVDF membrane type is increasingly being adopted in predominantly sewage treatment and factories’ wastewater facilities. MCC then further developed the PVDF membrane to have the same environmental performance as the PE membrane. As a result, since 2013, the PVDF membrane has seen increased use in drinking water treatment facilities.

By interweaving the straw-shaped hollow fiber membranes into a sheet, and then either creating multiple layers or folding the sheet into a tubular shape, STERAPORE™ can create up to severalfold the membrane surface area of flat membranes. Not only does the material boast excellent filtration performance, but it can also help to make facilities more compact. The material has a range of other advantages, too—as the membrane quality can be easily visually inspected, the replacement cycle is extended, reducing costs throughout the service life of the membrane.

- Taking on New Markets and Domains

-

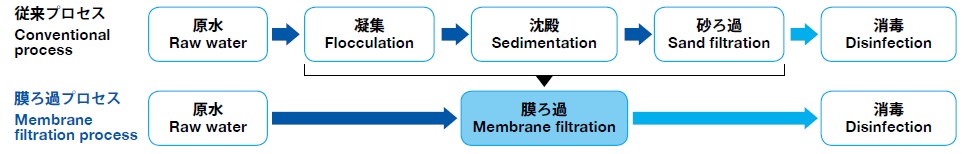

Drinking water purification comparison

Taking on New Markets and Domains

With over 5,000 projects installed worldwide, water treatment systems using STERAPORE™ are widely being used for the treatment of municipals and industrial wastewater. In particular, membrane bioreactors(MBR) —a wastewater treatment technology that combines biological treatment with membrane separation—are garnering worldwide attention. With no need for a sedimentation tank, MBR have a space-saving design, while also generating high-quality treated reusable water, unlike conventional systems. While improving its track record in Asia, where it holds a high share of the market, MCC is working to expand its global sales network to take the top spot worldwide.

In Japan, MCC is moving forward with the installation of submerged type PVDF membrane filtration equipment at water purification plants alongside Swing Engineering Corporation[別窓表示]. Technology centered on hollow fiber membranes can cover conventional processes such as flocculation, sedimentation, and sand filtration, enabling stable quality in treated water, more compact facilities, and simple maintenance and management. Using these strengths, MCC has begun making proposals for largescale projects that cover entire metropolitan areas.

In the future, MCC is looking at ways to contribute to the resolution of social issues using STERAPORE™. It is also making progress with initiatives that contribute to more environmentally friendly operations, such as proposals for reusing treated wastewater internally, and using hollow fiber membranes for gas separation and collecting CO2 from the flue gas.

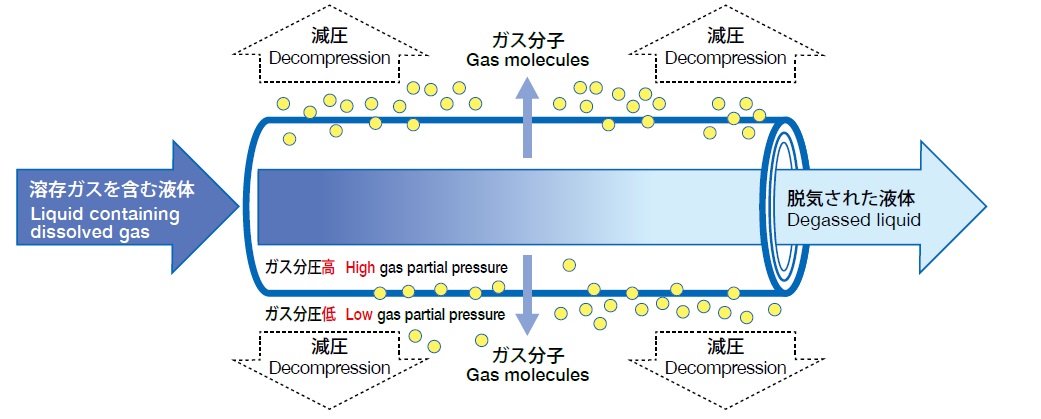

Solutions for Society Using Gas Separation

In inkjet printers and biochemical analyzers, dissolved gas is removed from the ink and blood samples to prevent malfunctions due to gas bubbles. This is done with multi-layered hollow fiber membranes MHF™. Using the capabilities of MHF™, we are currently examining the development of hollow fiber membranes that can remove specific gases from a mixture. Elsewhere, as we move toward a carbon-recycling society, Carbon dioxide Capture, Utilization, and Storage (CCUS) technology is attracting attention, and in environmental fields like this, too, we believe our hollow fiber gas separation membranes will be extremely effective.

- Degasification mechanism

-

Lowering the pressure on the outside generates gas pressure differences between the inside and outside of the hollow fiber membrane. In turn, gas molecules spontaneously move from the inside to the outside.