Please note: This contact form is managed by an external site.

- Mitsubishi Chemical Corporation

- Food / Healthcare Dept.

These are links for moving within this page

Dextranase reduces polysaccharide viscosity by dissolving the dextran in juice in the sugar manufacturing industry. This greatly reduces labor.

"Dextranase" page | Food & Healthcare Department Site[Open in a new window]

[Close]

Chaetomium gracile

Dextranase activity:3,900~4,800 u/g

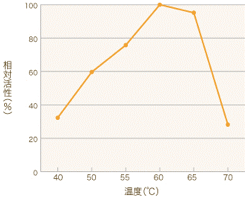

In the sugar industry, one major problem is caused by damage to beet and cane tissue resulting from the formation of polysaccharides, in particular dextran, on reaction with contaminating microorganisms. The formation of dextran in the sugar manufacturing process not only hinders filtration, but also retards crystallization, elongates sugar crystals, and reduces sugar recovery. DEXTRANASE 2F is derived from non-recombinant strains of Chaetomium gracile and is an endo-type dextranase, which exclusively hydrolyses the α-1,6-linkage of dextran and reduces the viscosity of the sugar juice rapidly and prevents sucrose crystal elongation. As DEXTRANASE 2F is a very stable enzyme at high temperatures, it is the best choice for the sugar manufacturing process.

[Close]

Dextran hydrolysate, Improvement of sugar yield.

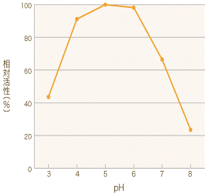

In laboratories, sufficient effects were obtained using approx. 10.4 units of Dextranase on 1g of dextran. Further, the sugar manufacturing industry required many high-temperature processes and heat resistance in the enzymes used, so Dextranase 2F is applicable as it can be used effectively up to 70ºC.

[Close]

|

Component |

Blending quantity (%) |

Notes |

|

DEXTRANASE |

25% |

Main agent |

|

Glycerin |

56% |

Vice agent |

|

Food ingredients |

19% |

Water |

20kg:PE container

200kg:(drum)liquid

[Close]

pH activity Temperature activity

Please note: This contact form is managed by an external site.

View the products of Food / Healthcare Dept., Mitsubishi Chemical[Open in a new window]

This is the end of this page