Characteristics

[Close]

Coke (from German "Koks") is manufactured by carbonizing (coking) coal at a high temperature of about 1200 ℃ in a coke oven. Coke is one of the essential raw materials for iron-making in blast furnaces. Coke mainly consists of carbon.

Mitsubishi Chemical's Kagawa plant has one of the world's largest coke ovens with 150 ovens and produces 1.5 million tons of high-quality coke per year. Each year, Kagawa plant imports 30-40 different types of coals from various countries. In order to ensure stability, over 10 types of coals are blended.

Applications

[Close]

Iron-making Raw Material

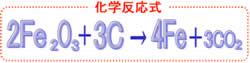

The coke has functions as heat source, reducing agent and spacer in blast furnaces.

Because it is more favorable for the oxygen to combine with carbon than with iron, the following change occurs in which oxygen is removed from iron.

Inquiries Concerning Products

View the products of Coke Dept., Mitsubishi Chemical[Open in a new window]