Aluminum Composite Material (ACM)ALPOLIC™

Mitsubishi Chemical Infratec Co.,Ltd.

ALPOLIC is Aluminum Composite Material (ACM) composed of two sheets of aluminum and the thermoplastic core.

ALPOLIC has been global leading ACM since 1970s and has been used worldwide in more than 130 countries.

We have a variety of product lineups with design and function using different types of materials on surface and core materials

including ALPOLIC A1 which passed European fire classification A1 as the first ACM in the world, ALPOLIC/fr series which passed fire regulations around the world, and ALPOLIC/fr SCM with stainless steel on its surface.

For the details of products, visit ALPOLIC dedicated website.

Characteristics

[Close]

- Lightweight and high rigidity

Lightweight and rigid material enables weight saving.

- Corrosion and weather resistance

The surface finish has excellent corrosion and weather resistance and the material is suitable for decorative use.

- Finish quality

Consistent finish quality is secured by a continuous coil coating system.

- Heat insulation, sound absorption, and vibration damping

A composition of the sandwiched structure provides less thermal conductivity, better sound absorption, and vibration damping properties.

- Flatness

High rigidity derives superior flat panel.

- Variety of finishes

Stone, timber, and natural metal look finishes are available.

- Easy processing and fabrication

It is easy to cut, bend, and fasten with conventional machines and tools for processing and fabrication.

- Fire safety

ACM with fire-retardant core (fr core)

- Water-resistance

Superior water or moisture resistance to steel or wood

- Easy and economical maintenance

Clean surface can last with simple cleaning and it will reduce running costs for the maintenance.

- Impact resistance

It is hard to break under impact load comparing with other board or sheet materials e.g. made of calcium silicate, cement, plaster and plastic.

- Recyclability

ALPOLIC is a recyclable material.

Titanium Composite Material (TCM):

National Grand Theater (Beijing, China)

Stainless Composite Material (SCM):

Marina Bay Sands (Singapore)

Applications

[Close]

ALPOLIC is used in many different applications due to its various characteristics.From the added safety with fire-retardant core material to the color variations through the use of high-quality, highly durable coatings as well as mirror finish options and variety of available metal materials,ALPOLIC is keep improving for customer satisfactions.

Building Exteriors

Marina Bay Sands(Singapore)

ALPOLIC products are in compliance with fire prevention standards in many countries and are used in many applications including some of the most famous landmarks in each country.

Building Interiors

Palace Building (Tokyo)

GaGa Milano shop (Tokyo)

Offering extensive lineup of attractive products in different styles such as metallic, woodgrain, marble, and mirror finish.

Exterior Building and Roof Materials

Bicycle parking roof

Applying to roofs as a non-combustible material for carports, bicycle ports, passageway shelters, and so on.

Signage

Canopy sign in a petrol station

Utilizing for signage area such as gas stations and car dealerships.

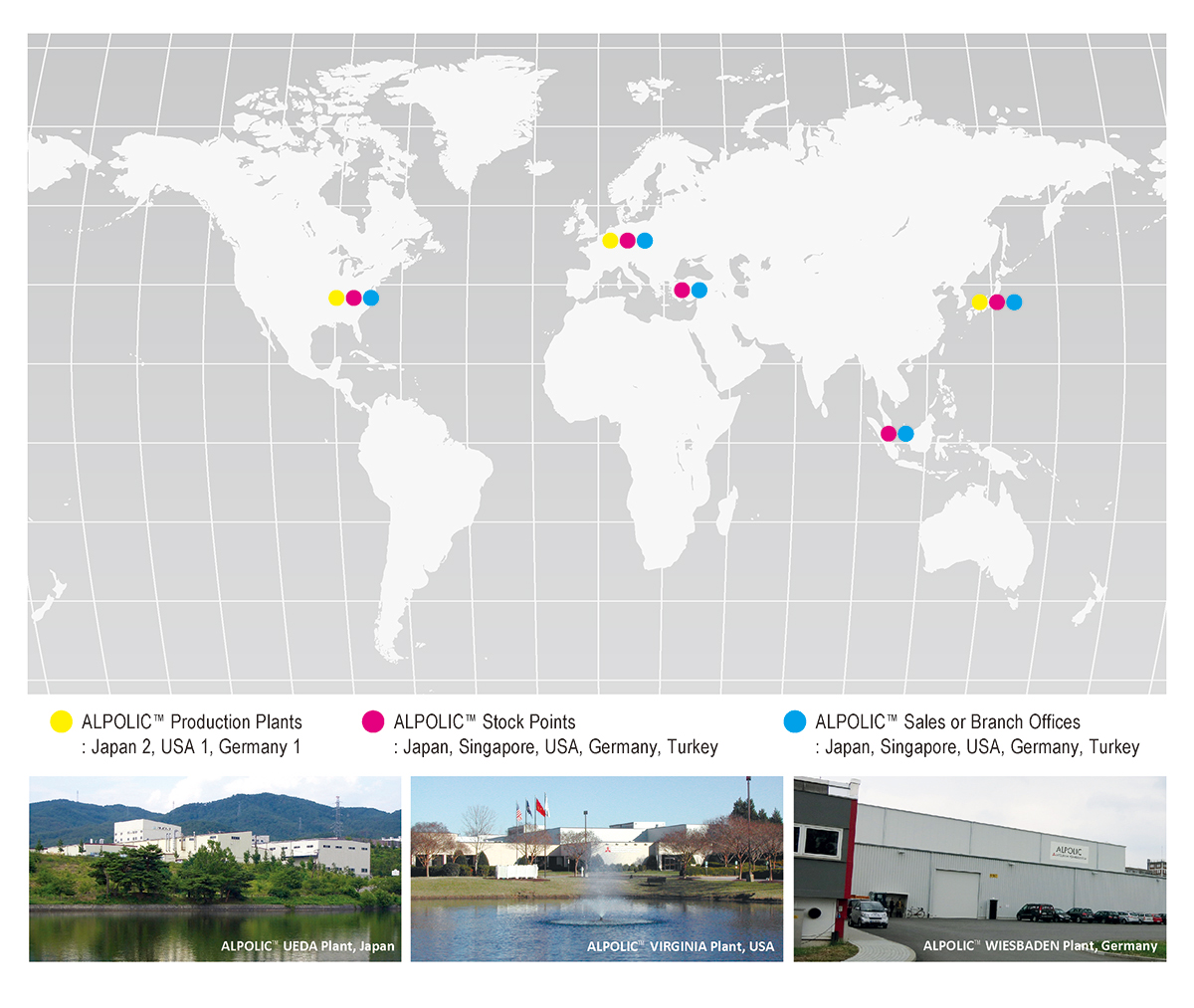

Global Development

[Close]

The ALPOLIC Business of Mitsubishi Chemical Group is in global sales operation with offices in Asia, Europe, and North America. ALPOLIC products are manufactured in Japan at our Ueda Plant in Nagano Prefecture, in North America at Virginia Plant, and in Europe at our Wiesbaden Plant in Germany.

Related Products

[Close]

ALPOLIC™/fr RF and ALPOLIC™ RF

The ALPOLIC surface is anodized and given a reflective finish. This reflective material will not break like glass. It is also lightweight and easy to fabricate. This product is ideal for interior, alternatives of full-length mirror, and display applications.

AL-LEADER™/AL-CHAMP™

This product combines a foamed plastic core with an extremely thin aluminum skin to achieve further improvements in weight and cost reduction. This also enables the material to be easily cut, drilled, and otherwise fabricated. Being light and also highly rigid, this material is often used in face panels for doors, signs, and equipment covers.

Inquiries Concerning Products

View the products of Mitsubishi Chemical Infratec[Open in a new window]