Case Study

Wind Power Generation

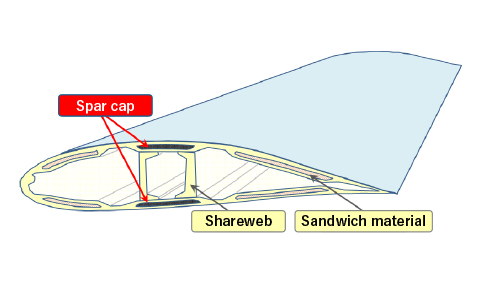

In the wind power generation market, progress with installation is being made mainly in Europe and China, and global demand is expected to continue to grow in future. In particular, demand for carbon fiber reinforced plastics (CFRP) is increasing as offshore wind power generation expands, and blades become larger. Here we introduce a case study of application to a spar cap.

Spar Cap:

Contributions to increased blade size and market expansion

A spar cap is a reinforcing plate that provides structure for the main girder. Carbon fiber reinforced plastics (CFRP) are often used for large wind turbine blades with diameters exceeding 100 meters.

Lighter weight and greater rigidity

- Reduction of blade deflection using the highly rigid carbon fiber reinforced plastics (CFRP).

- Being lighter than conventional glass fiber composite materials makes construction easier.

In the past, glass fiber composite materials have been used for wind turbine blades. Increase in the size of wind power generation blades means that there is a high probability of the blade striking the support pillar and breaking due to deflection if it is made of glass fiber composite material only. Therefore, the highly rigid carbon fiber reinforced plastics (CFRP) are required, and use of carbon fiber for wind power generation is increasing due to its light weight and ease of construction.