Case Study

Aircraft

In the aircraft industry, carbon fiber reinforced plastics (CFRP) have become indispensable materials for improving fuel efficiency by reducing aircraft weight.

They have a wide range of applications, from primary structural materials such as wings and fuselage, to secondary structural materials such as seats and floor panels.

New applications such as engine parts are expected in the future.

Here we introduce a case study of application to an engine structural guide vane.

Engine Structural Guide Vane:

The world's first engine structural guide vane for civil aircraft

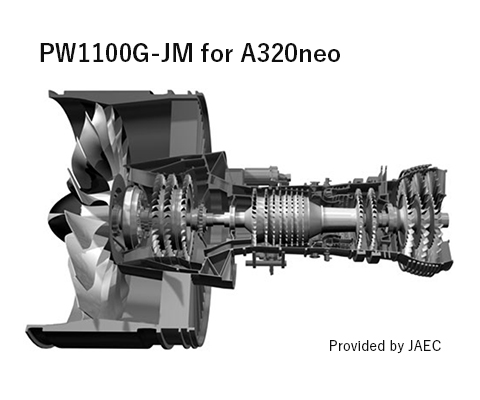

PAN-based, medium-elasticity-grade carbon fiber is used in the fan structural components of the engine PW1100G-JM for Airbus's new A320neo aircraft. PW1100G-JM is a civil aircraft engine developed on the basis of international collaboration by Pratt and Whitney (in the USA), MTU Aero Engines AG (in Germany), and Japanese Aero Engines Corporation (in Japan), involving establishment of a collaborative body, International Aero Engines LLC (IAE LLC). The structural guide vane that is positioned inside the fan and draws air in from the front of the engine is the first in the world to be made of composite material.

By increasing

the fan diameter

of civil aircraft engines,

fuel consumption is improved by 15%,

and noise reduction is achieved.

- Carbon fiber reinforced plastics (CFRP), which are lightweight and have high strength performance,

are materials used to achieve larger fan sizes. - Structural guide vanes further reduce weight by integrating the vane and structural components.

- Geared Turbo Fan, an advanced gear system with an increased fan diameter, enables reduced fan rotation speed, high propulsion efficiency, and reduced noise.

PW1100G-JM uses the advanced gear system Geared Turbo Fan, which has a bypass ratio of approximately 12, almost three times that of the current system, V2500, and this high bypass ratio enables high propulsion efficiency (low fuel consumption) and low noise.

By replacing the conventionally used titanium and aluminum with lightweight, strong carbon fiber reinforced plastics (CFRP), the engine diameter can be increased while maintaining sufficient strength to withstand bird collisions, contributing greatly to engine weight reduction and fuel efficiency improvement.

In addition, the structural guide vane now adopted has the function of a structural part that supports the fan case, thus achieving further weight reduction.

NB:

In a turbofan engine, the bypass ratio is the ratio between the flow rates of air flowing through the fan but not the engine (bypass air), and air flowing through the engine. The larger the bypass ratio, the more efficient the engine propulsion at subsonic speeds, the lower the fuel consumption rate at low speeds, and the lower the engine exhaust noise.

Thermoplastic CFRP

has both high impact resistance,

enabling it

to withstand bird collisions,

and high productivity.

The structural components of civil aircraft engine fans are subject to bird collisions during flights. High impact strength is required to ensure integrity as a structural component even after a bird collision. Our mid-elasticity-grade carbon fiber, which has shown very high impact resistance, is used in thermoplastic CFRP to achieve high productivity, and has been accepted for use in the PW1100G-JM structural guide vane, which is currently in mass production and commercial distribution.

In addition, we conduct rigorous quality control in accordance with Aerospace Quality Control System JISQ9100, and we develop, produce and distribute materials that are appropriate for a wide range of structural and interior applications in aircraft.

In future, progress is expected with application of CFRP composite materials to aircraft engines, as they become larger, and require lighter materials. We will strive to increase the applications of carbon fiber in aircraft engine parts, making use of the opportunities to use it in structural guide vanes.