|

|

| July 30, 2009 |

| Mitsubishi Rayon Co., Ltd. |

|

|

Announcing launch of ACRYPLEN 3D-MR |

|

New acrylic film combines excellent

heat-moldability with superior mar- resistance |

|

|

Mitsubishi Rayon Co., Ltd. announces a new addition to its ACRYPLEN series of acrylic films. ACRYPLEN 3D-MR, which goes on sale in August 2009, is a film made by coating a special light-cured acrylic resin onto ACRYPLEN. For this reason, we have named this product 3D (three-dimensional) MR (mar-resistance).

|

|

| Background to development of ACRYPLEN 3D-MR |

|

Mitsubishi Rayon's ACRYPLEN series of acrylic films all exhibit excellent weatherability, transparency, and heat-moldability, and enable users to achieve attractive decorative effects such as a jet-black color or a metallic sheen after printing or vapor deposition processes. For these reasons, these products are widely used in such fields as construction materials, reflective materials, and automobile interior materials. They are also employed as alternatives to paint undercoatings, thus avoiding the need to use organic solvents and thereby lowering the environmental burden imposed by normal painting processes.

While the market applications of the ACRYPLEN series have been expanding, the need for more mar-resistant films has been growing. The problem hitherto has been that the application of a hard coating to a film reduces its heat-moldability, resulting in cracks and bleaching. By applying a light-curing process after heat-molding, Mitsubishi Rayon has succeeded in creating an acrylic film that exhibits both three-dimensional heat-moldability and mar-resistance.

|

|

|

| Features of ACRYPLEN 3D-MR |

| 1. |

Combines superior heat-moldability and mar-resistance |

| 2. |

Boasts excellent chemical resistance |

|

|

|

| Expected applications of ACRYPLEN 3D-MR |

| Vehicle exterior and interior materials, external casing materials for IT equipment and electronic appliances |

|

|

| Product specifications |

|

The product comes in roll form

|

| 1. |

83μ (film thickness 75μ + 3D-MR layer of 8μ): 1,040mm-wide strip, 700-meter roll |

| 2. |

133μ (film thickness 125μ + 3D-MR layer of 8μ): 1,040mm-wide strip, 500-meter roll |

|

|

|

| Initial sales target |

| 100,000 square meters per month |

|

|

| For reference: |

| 1. |

Configuration of product |

|

|

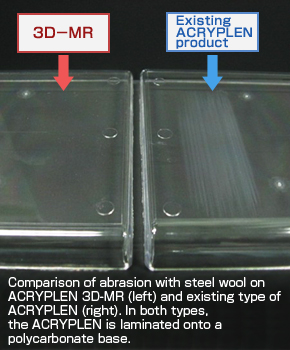

| 2. |

Mar- resistance comparison |

|

|

|

|

|

| For further inquiries, please contact: |

| Public and Investor Relations Office |

|

|

|

The contents shown herein are accurate as of the time of posting.