|

|

| October 7, 2002 |

| Mitsubishi Rayon Co., Ltd. |

|

|

| Gas diffusion layer developed for

Proton Exchange Membrane Fuel Cells |

|

| Mitsubishi Rayon will set up a commercial

production line within the Toyohashi Production Center with

the aim of producing gas diffusion layers (GDLs) used in proton

exchange membrane fuel cells(PEMFC). |

|

|

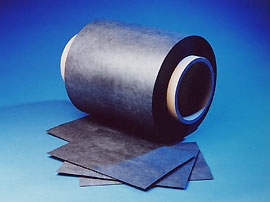

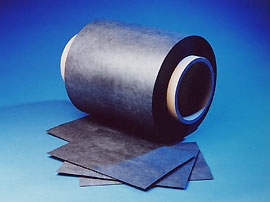

GDLs are key components of

electrodes in fuel cells, required not only gas permeability

and electrical conductivity as the physical properties, but

also ease of handling and cost reduction in mass production

of PEMFC. The PYROFILTM GDL that has been developed

by Mitsubishi Rayon is of the rolled carbon paper format, utilized

advanced technologies of our core acrylic fiber manufacturing

and carbon fiber manufacturing to improve the flexibility of

carbon paper, and enable mass production by making the manufacturing

process continuous.

We recently examined the manufacturing technology and conducted

pre-marketing for the production of 30 cm-wide continuous rolls of GDL at the

Corporate Research Laboratories (Otake City, Hiroshima Prefecture). We have received

a large number of inquiries from domestic and overseas fuel cell and membrane

electrode assembly (MEA) manufacturers, and on the basis of our forecast that

the fuel cell market will be fully developed in 2004, we decided to establish

a mass production line within the Toyohashi Production Center.

The new line will enable the production of GDL up to 80 cm

width. We have a target production capacity of 250,000 square meter annually,

and plan to increase our capacity to meet future demand. We are planning to make

our first shipments from the new line in January 2003.

In 1998, Mitsubishi Rayon invested in Dynetek Industries Ltd.,

a Canadian manufacturer of high-pressure containers, and began supplying them

with carbon fiber. Dynetek manufactures compressed natural gas (CNG) tanks and

hydrogen tanks for vehicles powered by fuel cells. As our development of the

gas diffusion layer is timely, we are able to make a direct offer of a key component

to the proton exchange membrane fuel cell market, and we expect to expand our

business due to these synergistic effects. As part of a project to find broader

industrial uses for carbon fiber, we are developing new markets for carbon fiber

in the fields of energy and environmental production.

|

|

|

|

Rolled gas diffusion

layer for fuel cell

reference

materials: |

|

|

|

Dynetek Industries Profile

1. Company

name: Dynetek Industries Ltd.

2. President:

Robb Thompson

3. Head

Office: Calgary, Alberta, Canada

4. Establishment:

1990

5. Paid-in

capital: CA$50.25 million

6. Equity

stake: Mitsubishi Rayon - 7.5% (Capital participation

in June 1998)

7. Business

lines: Light-pressure gas tank manufacture and sales

8. Sales:

CA$8,013 thousand (term ended December 2001)

9. Employees:

68 |

|

|

| For further informaiton,please contact

to: |

|

| Public & Investor Relations Office:tel

+81-3-5495-3100 |

e-mail : koho@mrc.co.jp |

| Carbon Fiber & ACM Division |

e-mail : gdlinfo@mrc.co.jp |

|

|

The contents shown herein are accurate as of the time of posting.