Inquiries Concerning News

Corporate Communications Div.,

The Mitsubishi Chemical Group

TEL: +81-3-6748-7140

Mitsubishi Plastics develops a new high gas-barrier SiOx film for Retort-food packaging,

Jan. 29, 2015

Mitsubishi Plastics, Inc. (Head Office: Chiyoda-ku, Tokyo; President: Takumi Ubagai) developed a new transparent high barrier SiOx coated film for retort-food packaging named “TECHBARRIERTM LS”.

“TECHBARRIERTM LS” improves highly oxygen and water vapor barrier properties compared to the current “TECHBARRIERTM*” series.

The oxygen transmission rate is 0.1 cc/(m2•d•atm) (measurement condition: 25°C, 80% RH), the water vapor transmission rate is 0.1 g/(m2•d) (measurement condition: 40°C, 90% RH).

The higher barrier of “TECHBARRIERTM LS” will benefit a longer shelf, the transparency will deliver readily visible, microwavable retort packaging.

Both of them will bring an innovative packaging to switch from glass bottles and metal cans. It can contribute “New Carbon Society” and “KAITEKI*”.

Mitsubishi Plastics will launch “TECHBARRIERTM LS” on 1st April, 2015.

Mitsubishi Plastics aims to complement its diverse product portfolio in barrier film business through the development and sales of “TECHBARRIERTM LS”.

* TECHBARRIERTM

“TECHBARRIERTM” is a transparent high gas-barrier film in which SiOx (Silica)* is vacuum-deposited with added oxygen and water vapor barrier by Mitsubishi Plastics developed original technologies. Thanks to the unique technologies, it’s making more practical for a wide range of uses, including as a packaging material for food, pharmaceutical, industrial, and cosmetic contents, or as a comportment of a protect sheet for photovoltaic.

* SiOx (Silica, Silicon oxide)

Silica is a silicon oxide that constitutes about 60% of the earth’s crust. This is one of the most common materials on earth.

* KAITEKI

KAITEKI, an original concept of the Mitsubishi Chemical Holdings Group, means “a sustainable condition which is comfortable for people, society and the earth, transcending time and generations.”

Through our corporate activities, we realize KAITEKI by proposing new value that contributes to resolving environmental and social issues in various fields including living, information and electronics, health and medical care, environment and energy. This is the corporate ideal that the Mitsubishi Chemical Holdings Group seeks to realize.

[Main features of TECHBARRIERTM LS]

1. Superior oxygen and water vapor barrier properties

2. Retortable, keeping high-barrier characteristics even after retort sterilization

3. Gelbo-Flex Durability, keeping high-barrier characteristics even after gelbo flex test

4. Metal free, available to use metal detector, microwave oven

5. Easy to print on

6. Superior acid resistance and oil resistance. High barrier property is maintained even for vinegar and oil contained in retort pouch

7. No chlorine gas is emitted if burnt in isolation

[Gas Barrier Property ]

| TECHBARRIERTM LS | Our conventional products | ||

|

Oxygen transmission rate |

Pre-retort | 0.1 | 0.5 |

| Post-retort (121°C × 30 minutes) |

0.2 | 0.5 | |

| ater vapor transmission rate g/(m2•d) Measurement conditions: 40°C/90% RH |

Pre-retort | 0.1 | 0.5 |

| Post-retort (121°C × 30 minutes) |

0.3 | 0.5 | |

[Measurement sample]

Laminated film with TECHBARRIERTM LS, BOPA, and polypropylene

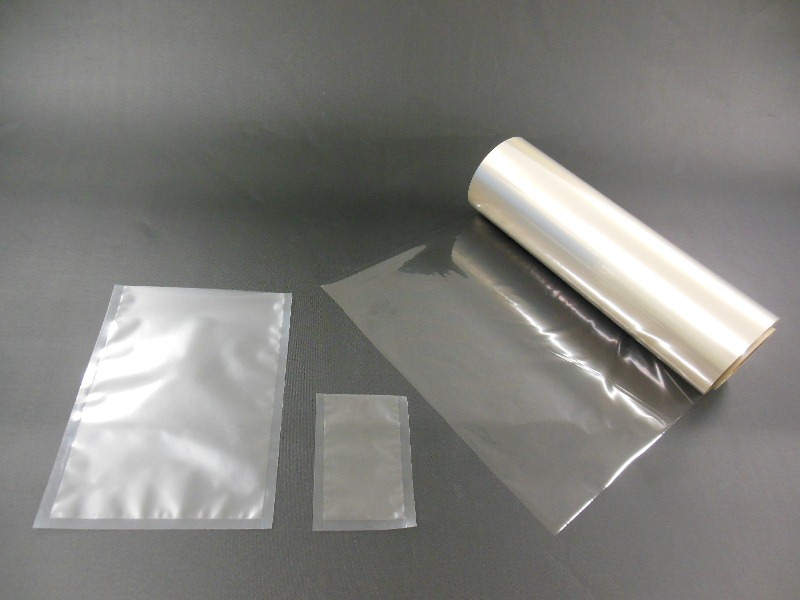

Photo: TECHBARRIERTM LS film and sample packages

< media contact >

Public Relations and Investor Relations office,

Mitsubishi Chemical Holdings Corporation.

TEL: +81-3-6748-7140