Inquiries Concerning News

Corporate Communications Div.,

The Mitsubishi Chemical Group

TEL: +81-3-6748-7140

Mitsubishi Plastics establishes a production line for alumina fiber

Aug. 5, 2014

Mitsubishi Plastics, Inc. (Head Office: Chiyoda-ku, Tokyo; President Takumi Ubagai) has decided to construct an additional line for “MAFTEC™”, alumina fiber. The new line is to be installed at its Sakaide Plant located in Sakaide City, Kagawa Prefecture.

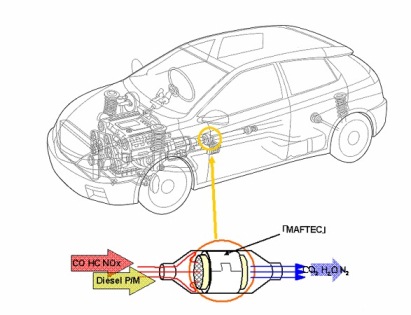

MAFTECTM is being manufactured at the company’s Sakaide and Naoetsu plants. It has various excellent properties, including the ability to maintain a long-term heat-insulating performance and cushioning effect even under temperatures topping 1,600 degrees C. For this reason, it has been given high reputation from customers as heat insulation material in steel mills and supporting material for catalytic converters and DPF* used in automotive exhaust gas treatment systems. More specifically, its share of the global market for supporting materials for catalytic converters and DPF* reaches about 40 percent (as estimated by Mitsubishi Plastics).

At present, we are coping with the surging demand in the market associated with automotive exhaust gas treatment systems by steps such as increasing the capacity of our existing production lines. We nevertheless are projecting that the limits to our supply with our current capacity (about 6,000 tons per year) will be reached in fiscal 2015. In response, we made the aforementioned decision to add a capacity of about 500 tons per year to our manufacturing facilities. We also decided to make this expansion at our Sakaide Plant. This is because the time required for the construction can best be shortened by use of the existing infrastructure there, and because that plant can response most swiftly to the surging demand in the market. The construction is slated for completion in the spring of 2015.

There is a movement under way for tightening restrictions on exhaust emissions in countries around the world. Along with this trend, the demand for alumina fiber is forecast to continue expanding, mainly in connection with supporting material for catalytic converters and DPF* used in automotive exhaust gas treatment systems. Mitsubishi Plastics is considering a further expansion of capacity in order to provide for a stable supply as a manufacturer while monitoring the situation in the market.

*DPF: Diesel particulate filter

(a unit for purification of exhaust by removal of soot-form substances emitted from diesel engines)

Alumina fiber MAFTECTM

Support mat for catalytic converters for exhaust-gas treatment equipment in cars

< media contact >

Public Relations and Investor Relations office,

Mitsubishi Chemical Holdings Corporation.

TEL: +81-3-6748-7140