Inquiries Concerning News

Corporate Communications Div.,

The Mitsubishi Chemical Group

TEL: +81-3-6748-7140

Mitsubishi Plastics launches a compact adsorption chiller with the highest cooling capacity per volume in the world

Mar. 14, 2012

Mitsubishi Plastics, Inc. (head office: Chuo-ku, Tokyo; President Hiroshi Yoshida) has developed in collaboration with Union Industry Co., Ltd. a compact adsorption chiller with the highest cooling capacity per volume in the world1. This new chiller (cooling capacity of 10kW) uses a heat exchanger coated with “AQSOATM”, the Company’s unique zeolite-based adsorbent which can efficiently remove water vapor at low temperatures. It can be incorporated into a waste heat recycle/cogeneration system for industrial sites, thus significantly reducing electricity consumption and saving energy. Mitsubishi Plastics plans to launch the chiller from April 2012.

“AQSOATM” is a zeolite-based vapor-adsorbent material that can absorb and desorb water vapor more efficiently in a relatively low temperature range (50-80°C) compared with conventional ones such as silica gels. By applying a heat exchanger coated with “AQSOATM” to an adsorption chiller, it becomes possible to make efficient use of low-temperature waste heat, thereby significantly reducing electricity consumption of the chiller. “AQSOATM” has already been used for large adsorption chillers with a cooling capacity of 100-350kW in the Japan as well as for compact adsorption chillers distributed in the EU, gaining a high reputation for its quality around the world. In addition, Mitsubishi Plastics has launched in January 2012 compact adsorption Chiller U-TYPE, an adsorption chiller with an integrated cooling tower developed in collaboration with Union Industry Co., Ltd.

The new chiller M-TYPE (cooling capacity of 10kW) to be launched in April has the world’s highest cooling capacity per volume. This was achieved by improving the application process of “AQSOATM” to a heat exchanger with a triple amount of the adsorbent. The new chiller enables plants to optimally reduce electricity consumption by up to 50% if it is applied to a waste heat recycle system, or up to 20% if it is applied to a cogeneration system. The chiller is not an integrated type with a cooling tower, but it is designed for easy connection. Furthermore, the chiller can be connected with a multiple number to a general cooling tower, making it possible to provide a cooling capacity of more than 10kW if needed.

Recognizing the ever-increasing awareness of environmental issues such as electricity/energy saving due to energy depletion and higher electricity rates as well as CO2 emissions reduction, Mitsubishi Plastics aims to achieve its sales target of 3 billion yen for the compact adsorption chiller series by 2015.

1 Projection of Mitsubishi Plastics calculated based on the published data of adsorption chillers on the market.

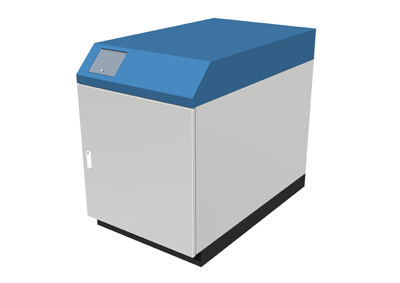

Product image: compact adsorption chiller M-TYPE

External size: Length 1,340mm x Width 800mm x Height 1,150mm

Inquiries by media regarding this material should be directed to the

Public Relations Section, General Administration Dept., Mitsubishi Plastics Inc.

TEL: +81-3-3279-3800