Inquiries Concerning News

Corporate Communications Div.,

The Mitsubishi Chemical Group

TEL: +81-3-6748-7140

Test-Market Compact Adsorption Chiller with Integrated Cooling Tower to the U.S. Market

Jan. 17, 2012

| Mitsubishi Plastics, Inc., in collaboration with Union Industry Co., Ltd., has developed an easy-to-install compact adsorption chiller with an integrated cooling tower (cooling capacity of 10 kW). The chiller, which uses the zeolitic water vapor adsorbent AQSOATM, is capable of being incorporated into a solar water-heater, making it possible to significantly reduce electricity use and save energy. Mitsubishi Plastics will start test-marketing the chiller to the U.S. market beginning January 23, 2012. Since 2008, Mitsubishi Plastics (Headquarters: Chuo-ku, Tokyo; President: Hiroshi Yoshida) has been manufacturing parts, such as heat exchangers, coated with AQSOATM, a zeolitic water vapor adsorbent that is able to efficiently release water vapor – even at relatively low temperatures (140℉-176℉). Since heat exchangers coated with AQSOATM are able to reduce the consumption of energy, the parts are already being used in many adsorption chillers (cooling capacity of 9-350 kW) in Japan and Europe, with the product performance being praised around the world. |

Photo of the product

|

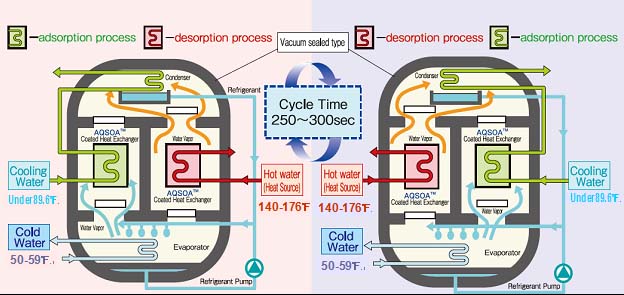

●Mechanism of the Adsorption Chiller:

For economic reasons, air conditioning units using compressors, not adsorption chillers, have traditionally been used in small facilities. However, there is a growing demand across the globe for energy efficient air conditioning units that can reduce CO2 emissions.

To address such issues, Mitsubishi Plastics and Union Industry have developed a compact adsorption chiller, featuring an easy installation process. This compact adsorption chiller can be used for cooling data centers or domestic houses through the use of hot water from solar water heaters and cogeneration systems, or by waste heat from small factories.

When combined with a solar water-heater*, the cooling performance of this product throughout the day will be superior by 50% from that of traditional silica gel adsorption chiller. (The temperature of recycled water is assumed at 149℉.)

When the product is combined with a cogeneration system, the system is expected to reduce electricity consumption by up to 20% from that of coolers with compressors (based on Mitsubishi Plastics research). In addition, the superior durability of AQSOATM reduces running costs due to fewer maintenance requirements.

Furthermore, with the technology of the adsorption chiller developed by Union Industry and the knowledge of cooling towers that Mitsubishi Plastics has long cultivated, for the first time in the world, the adsorption chiller and cooling tower have been integrated, making it significantly easier to install the system in comparison with traditional products.

Mitsubishi Plastics will exhibit this easy-to-install compact adsorption chiller with an integrated cooling tower at the International Air-Conditioning, Heating, Refrigerating Exposition (AHR EXPO) to be held in Chicago from January 23–25, and additionally, will conduct various marketing activities to sell the product to the U.S. market.

*In certain cases, this enables federal and states tax credits for energy efficiency.

| ■For more information, please contact: | |

|

Dr. Hiroyuki KAKIUCHI, |

|